Preparation method for bionic super-hydrophobic graphene thin film on aluminum alloy surface

A graphene film and aluminum alloy surface technology, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems of chloride ion corrosion and limit the application of aluminum alloy, and achieve high reproducibility and high Stability and durability, effect of uniform hydrophobic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for preparing a biomimetic superhydrophobic graphene film on an aluminum alloy surface, specifically comprising the following steps:

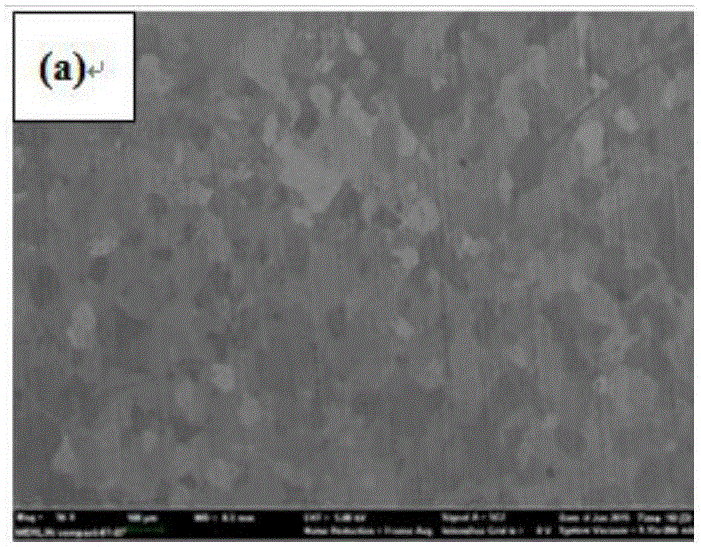

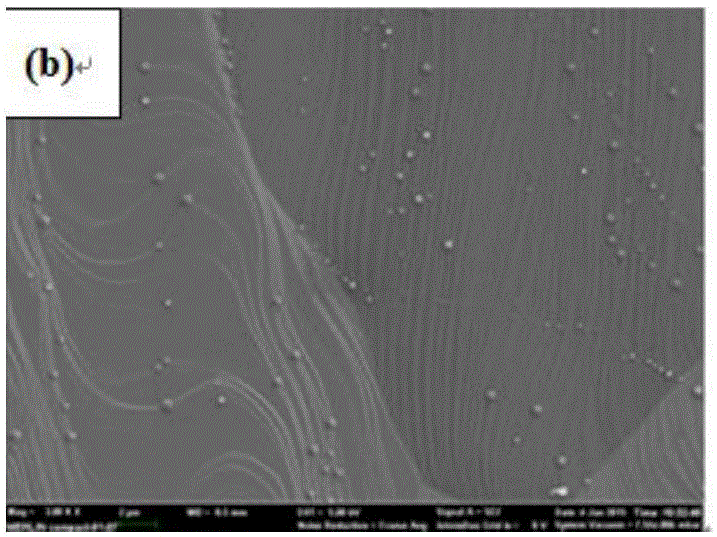

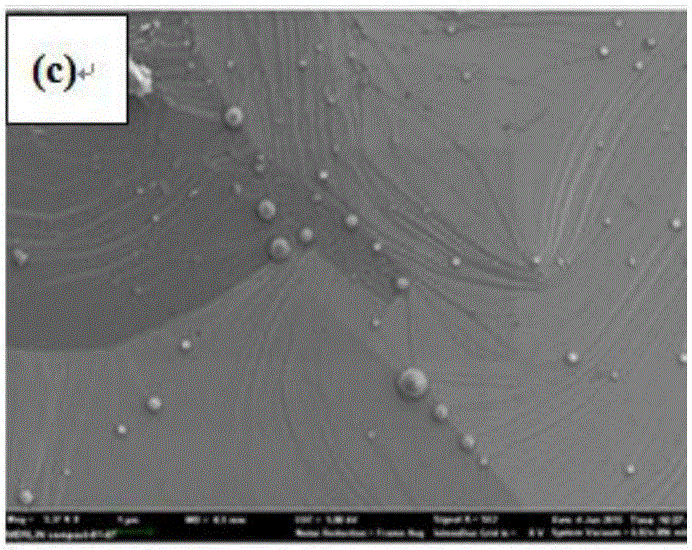

[0048]Aluminum alloy machining: choose 2024 aluminum alloy as the substrate, and perform bionic microstructure processing on the surface of the aluminum alloy. First, the aluminum alloy substrate was cut into splines with a size of 15×15×1 mm. Next, the surface of the cut aluminum alloy is polished with 400-2000 mesh sandpaper, in order to remove the oxide layer on the surface. Then, it was polished and cleaned ultrasonically in absolute ethanol for 10 min, and finally dried in a vacuum oven at 80°C for 2 h. Finally, using mechanical processing technology, an array of cylindrical convex hull structures is processed on the surface of the aluminum alloy. The diameters of the cylindrical convex hulls are 100 μm and 250 μm, the height of the convex hulls is 10 μm, and the distance between adjacent convex hulls is 200 μm and 350 μm....

Embodiment 2

[0053] A method for preparing a biomimetic superhydrophobic graphene film on an aluminum alloy surface, specifically comprising the following steps:

[0054] Aluminum alloy machining: choose 2024 aluminum alloy as the substrate, and perform bionic microstructure processing on the surface of the aluminum alloy. First, the aluminum alloy substrate was cut into splines with a size of 15×15×1 mm. Next, the surface of the cut aluminum alloy is polished with 400-2000 mesh sandpaper, in order to remove the oxide layer on the surface. Then, it was polished and cleaned ultrasonically in absolute ethanol for 10 min, and finally dried in a vacuum oven at 80°C for 2 h. Finally, using mechanical processing technology, an array of cylindrical convex hull structures is processed on the surface of the aluminum alloy. The diameters of the cylindrical convex hulls are 100 μm and 250 μm, the height of the convex hulls is 10 μm, and the distance between adjacent convex hulls is 200 μm and 350 μm...

Embodiment 3

[0059] A method for preparing a biomimetic superhydrophobic graphene film on an aluminum alloy surface, specifically comprising the following steps:

[0060] Aluminum alloy machining: This patent selects the aluminum alloy of grade 2024 as the substrate, and performs bionic microstructure processing on the surface of the aluminum alloy. First, the aluminum alloy substrate was cut into splines with a size of 15×15×1 mm. Next, the surface of the cut aluminum alloy is polished with 400-2000 mesh sandpaper, in order to remove the oxide layer on the surface. Then, it was polished and cleaned ultrasonically in absolute ethanol for 10 min, and finally dried in a vacuum oven at 80°C for 2 h. Finally, using mechanical processing technology, an array of cylindrical convex hull structures is processed on the surface of the aluminum alloy. The diameters of the cylindrical convex hulls are 100 μm and 250 μm, the convex hull height is 10 μm, and the distance between adjacent convex hulls i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap