High-performance steel bridge deck paving structure

A steel bridge deck, high-performance technology, applied in the direction of on-site coagulation pavement, bridges, bridge parts, etc. Good fatigue performance, strong interlayer adhesion, good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

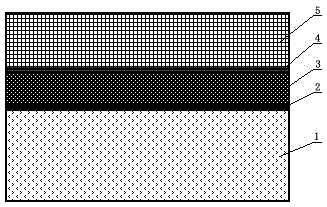

[0050] as attached figure 1 As shown, the present invention constitutes a complete bridge deck pavement layer with a waterproof adhesive layer 2, a sand-grain asphalt concrete layer 3, a modified emulsified asphalt adhesive layer 4 and a surface anti-skid wear layer 5 laid in sequence on the steel bridge deck 1. The structure, specific implementation steps and technical requirements are as follows:

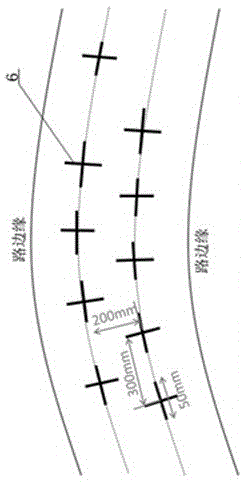

[0051] 1. Anti-skid structural surface setting: as attached figure 2 As shown, the eight-point welding process is adopted on the steel bridge deck 1, and the punched and rolled cross-shaped steel bar shear member 6 is set. The specification width×length×thickness of the cross-shaped steel bar shear member 6 is 5mm×50mm ×5mm, each row of cross-shaped steel bar shear members is arranged at a distance of 300mm in the curved direction and 200mm in the radial direction, and the centers of adjacent cross-shaped steel bar shear members in two adjacent rows are staggered 150mm rear arr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com