Glass curtain wall cleaning device

A glass curtain wall and cleaning equipment technology, applied in the direction of walls, building maintenance, building components, etc., can solve the problems of casualties and property, easy to scratch the glass surface, difficult to work, etc., to improve operational safety and prevent people from falling. effect of accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

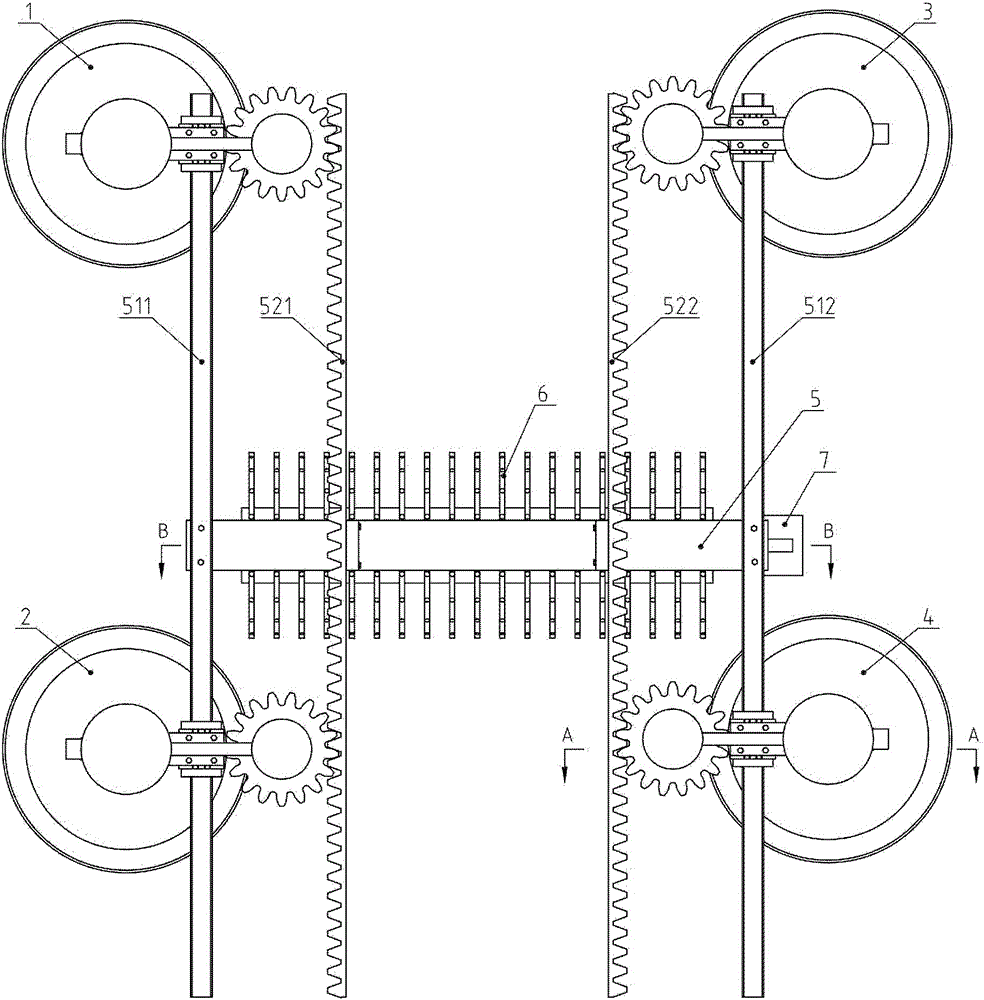

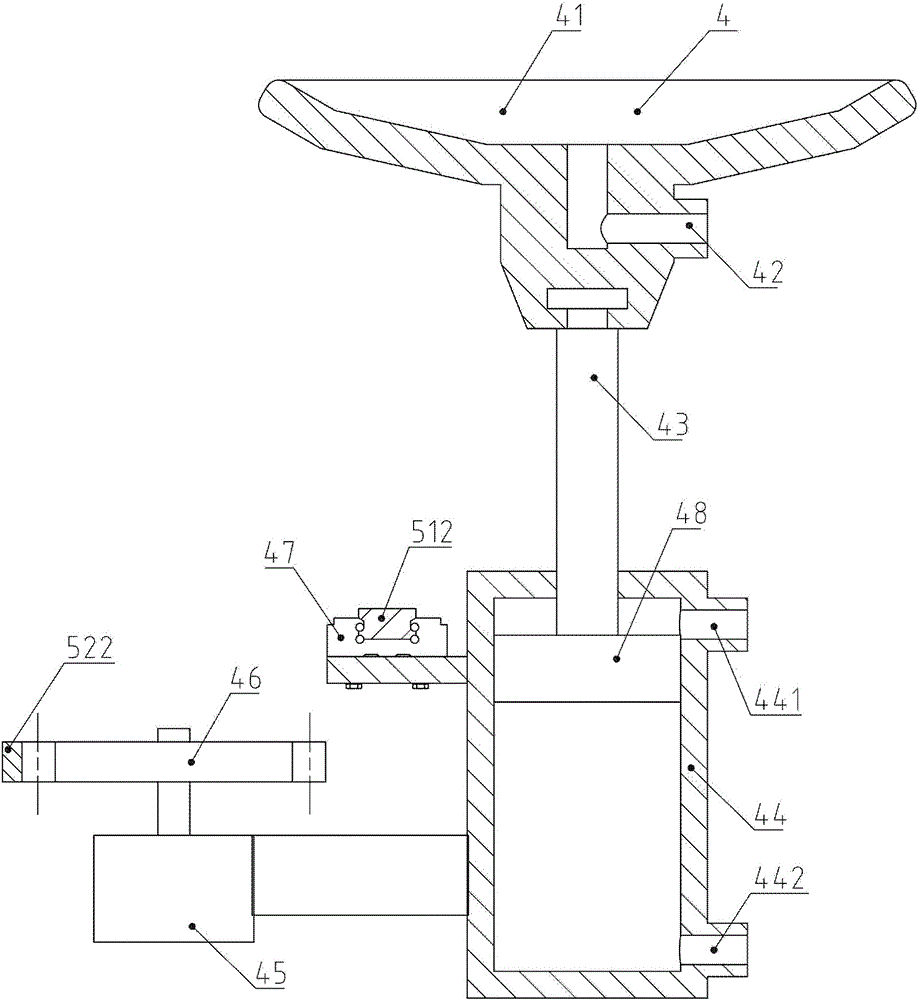

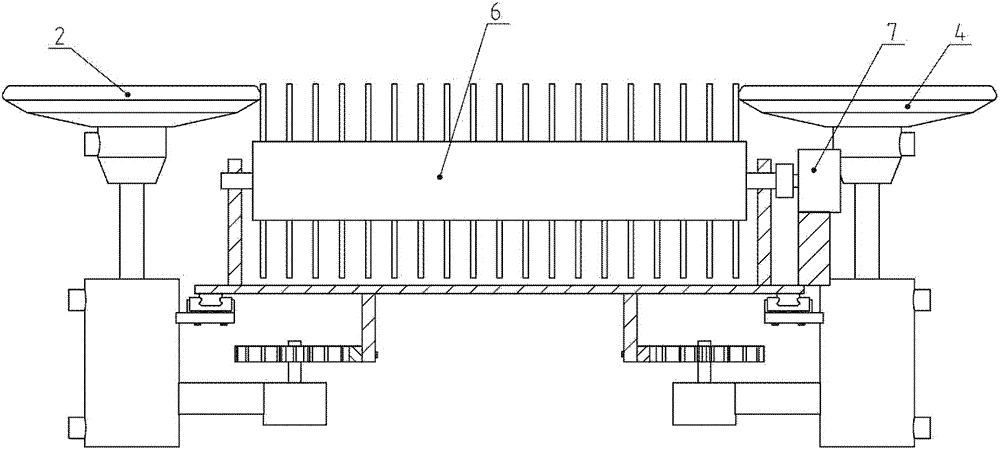

[0049] Embodiment 1: see Figure 1 to Figure 8 .

[0050] A glass curtain wall cleaning equipment, comprising a left upper suction cup assembly 1, a left lower suction cup assembly 2, a right upper suction cup assembly 3, a right lower suction cup assembly 4, a frame 5, a cleaning roller brush 6 and a cleaning motor 7; the frame 5 includes a left guide rail 511, Right guide rail 512, left rack 521 and right rack 522, these four parts are vertically arranged; Cleaning roller brush 6 has hairbrush on the circumferential surface, and cleaning roller brush 6 is connected with frame 5 through rotating pair, and cleaning motor 7 It is fixedly connected with the frame 5, and the output shaft of the cleaning motor 7 is connected with the shaft of the cleaning roller brush 6. When the cleaning motor 7 is energized and rotates, the cleaning roller brush 6 runs continuously, and the brush can continuously clean the surface of the glass curtain wall; The suction cup assembly 1, the lower...

Embodiment 2

[0072] Example 2: see Figure 9 to Figure 13 .

[0073] A glass curtain wall cleaning equipment, including a left upper suction cup assembly 1, a left lower suction cup assembly 2, a right upper suction cup assembly 3, a right lower suction cup assembly 4, a frame 5, a cleaning roller brush 6 and a cleaning motor 7; it also includes four walking cylinders 8 And cylinder rod-piston combination 9, walking cylinder barrel 8 and cylinder rod-piston combination 9 form walking cylinder, rear chamber air port 81 and front chamber air port 82 are arranged on walking cylinder barrel 8, and walking cylinder barrel 8 is fixedly connected with frame 5, The walking cylinder 8 and the cylinder rod-piston combination 9 form a moving pair. If the compressed air is connected to the air port 81 of the rear chamber or the air port 82 of the front chamber, the cylinder rod-piston combination 9 can reciprocate and translate along the moving pair; the cylinder rod-piston The end of the cylinder ro...

Embodiment 3

[0090] Embodiment 3: see Figure 14 .

[0091]This embodiment includes 6 suction cup assemblies, which are upper left suction cup assembly 1 , lower left suction cup assembly 2 , upper right suction cup assembly 3 , lower right suction cup assembly 4 , upper suction cup assembly 101 and lower suction cup assembly 102 . For a glass curtain wall with a relatively small area of single glass, many splicing seams, and a large number of rivets, if the suction cup is just at the seam or rivet, the suction cup and the glass surface will not be in good contact, and the adsorption effect will be lost. Let it idle temporarily, the other five suction cups can still work, wait until the suction cup is moved to avoid seams or rivets, and then let it continue to work.

[0092] Other structures, functions and beneficial effects are the same as those in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com