Improved sandwiched color-steel plate and manufacture and construction method thereof

A manufacturing method, color steel plate technology, applied in the direction of chemical instruments and methods, building structures, building components, etc., can solve problems such as easy to cause fire, not resistant to water, easy to absorb moisture, etc., to achieve improved application value and high insulation level , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

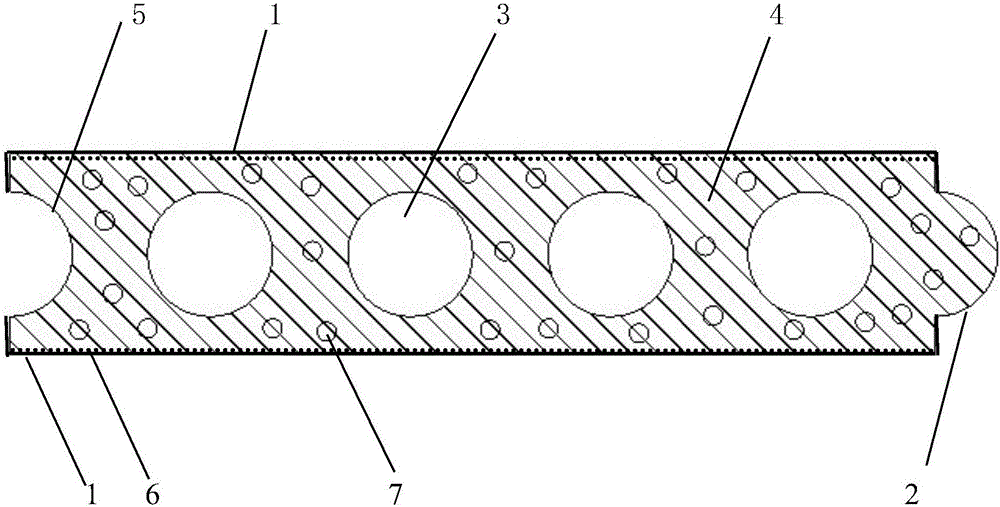

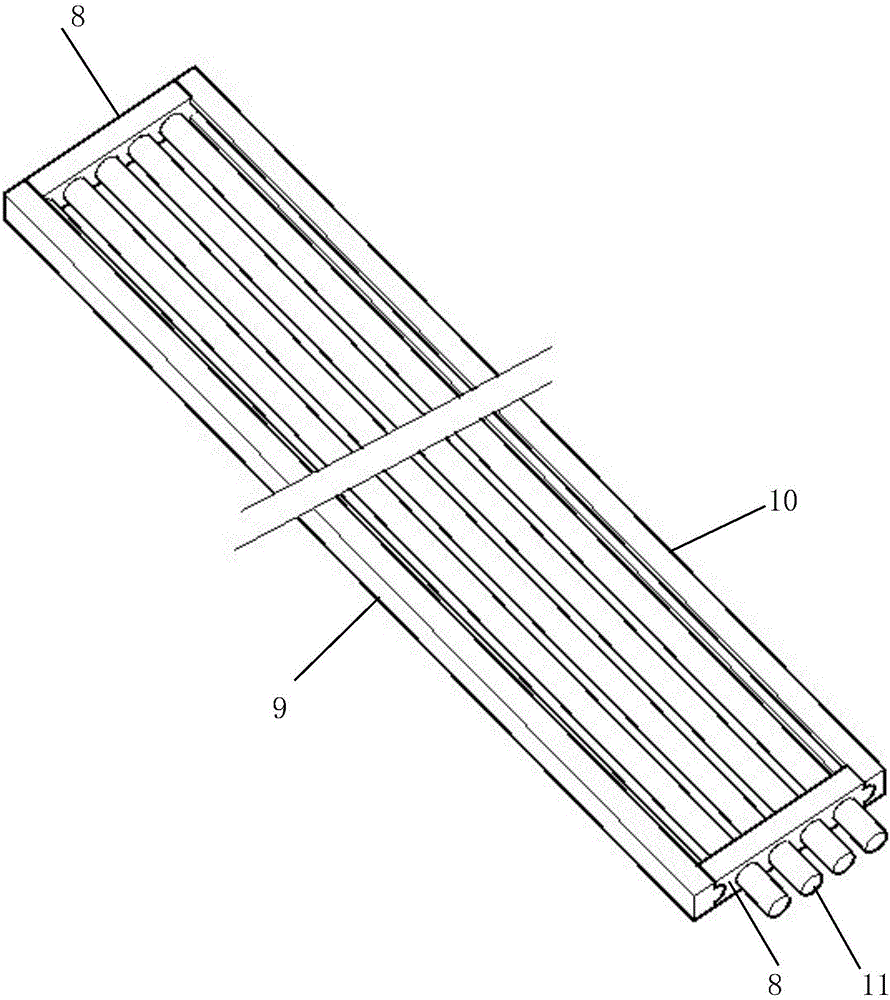

[0033] Embodiment 1: refer to attached Figure 1-3 , an improved sandwich color steel plate, including a panel 1 and a core plate 4, the color steel plate is in the shape of a rectangular plate, the core plate 4 is foam concrete, the core plate 4 is provided with a round hole 3 along the length direction, and the diameter of the round hole 3 is It is 1 / 3-2 / 3 of the thickness of the core board 4, set several according to the width of the core board 4, the distance between the two round holes 3 is usually 20-40mm, and the upper and lower sides of the round hole are 10-20mm away from the panel; the core board 4 There are panels 1 on both sides. The exterior of panel 1 is provided with blue or white or any color paint coating for protection and aesthetics. The lower part of panel 1 and core board 4 are provided with an adhesive layer, and the two sides of panel 1 face inward. Fold the edge at 90°, and the edge width is 10-20mm; one side of the core plate 4 is provided with a protr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com