Coaxial-output rotation and revolution transmission method and device

A technology of coaxial output and transmission device, which is applied in the direction of transmission device, gear transmission device, rotary piston type/swing piston type pump components, etc., and can solve the problems of inability to actively output rotation and revolution, wear and deformation of rotor and stator inner cavity, Problems such as low stability of the transmission system, to achieve the effect of improving high-speed stability, simple and compact structure, and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

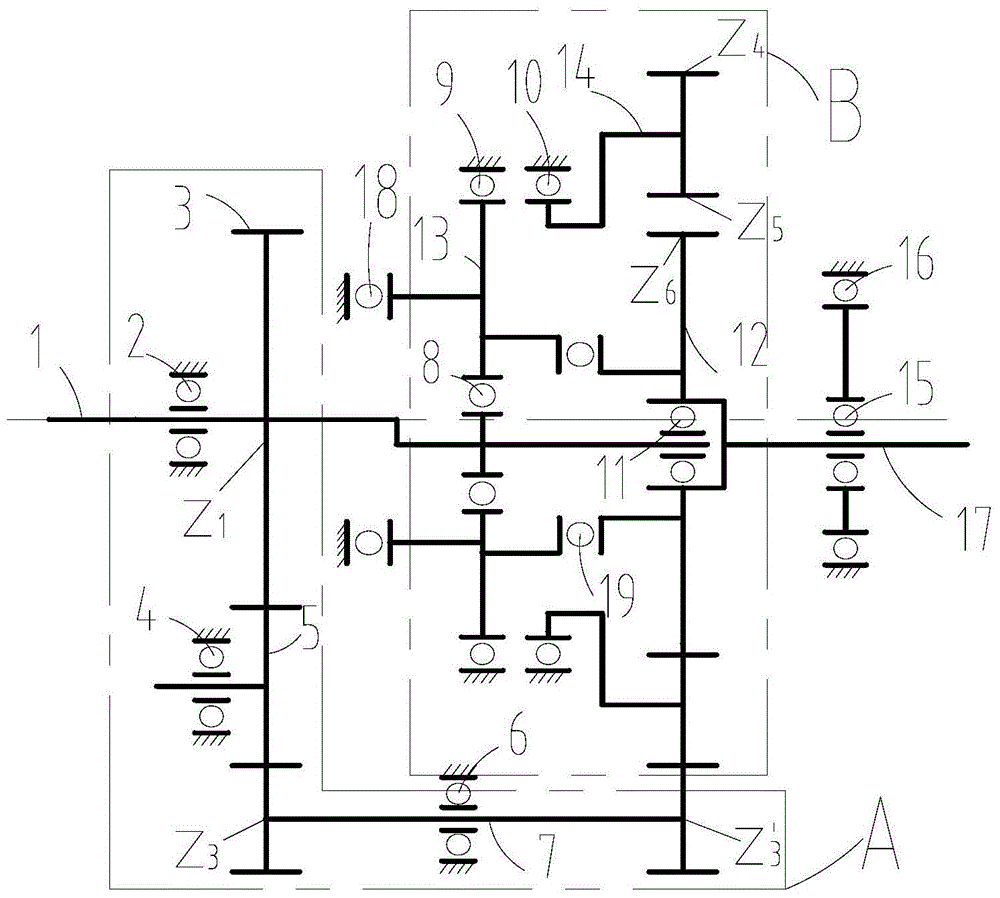

[0043] This embodiment is a transmission method for coaxial output rotation and revolution. The power input shaft is an eccentric shaft, including a connected main shaft and a shaft; the power output shaft revolves around the main shaft axis of the power input shaft, and at the same time the power output shaft revolves The axis rotates at a constant speed and reverses, and can bear axial loads, specifically:

[0044] The power input shaft is transmitted through the K-H-V planetary gear train with small tooth difference, so that the axis of the power output shaft coincides with the shaft axis of the power input shaft, and the power output shaft revolves around the main shaft axis of the power input shaft, and the revolution speed is the same as that of the power input shaft. At the same time, the active force of the power input shaft is superimposed by the transition gear system and the K-H-V planetary gear system with small tooth difference, so that the power output shaft produ...

Embodiment 2

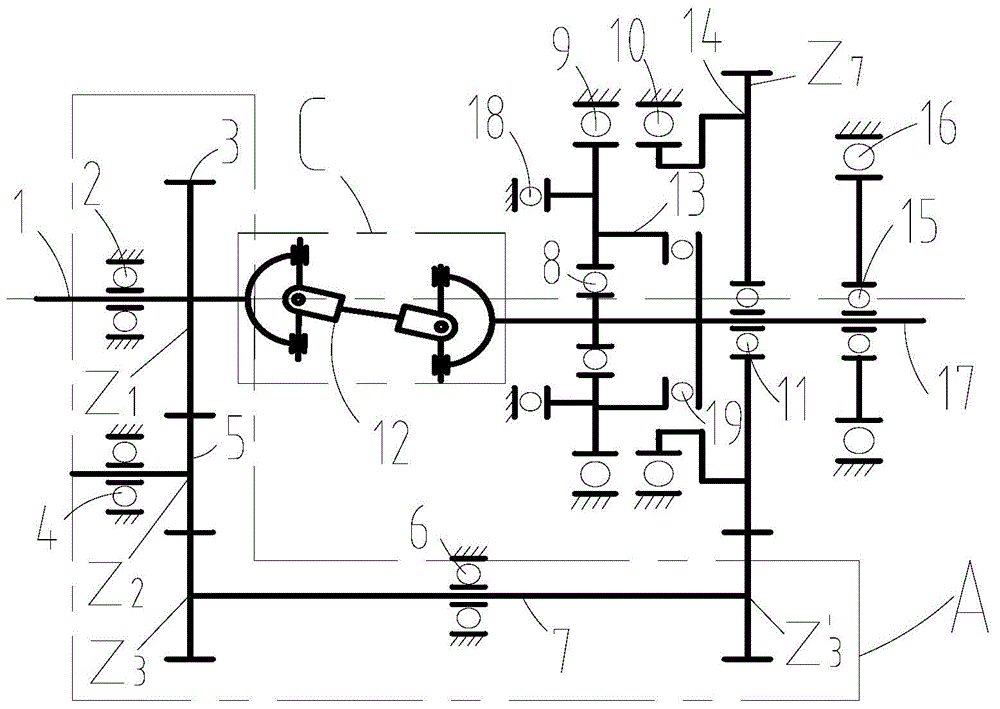

[0053] This embodiment is a transmission method for coaxial output rotation and revolution. The power output shaft revolves around the axis of the power input shaft, and at the same time, the power output shaft rotates at a constant speed and reverse around its own axis, and can bear axial loads. Specifically for:

[0054] The axis of the power output shaft is eccentric with respect to the axis of the power input shaft by using the power input shaft through the universal joint transmission system, and through the transmission of the transition gear system, the power output shaft revolves around the axis of the power input shaft, and the revolution speed and power The rotational speed of the input shaft is equal, and the revolution direction is opposite to that of the power input shaft; at the same time, the active force of the power input shaft passes through the transmission of the universal joint drive system, so that the power output shaft produces an autorotation motion at ...

Embodiment 3

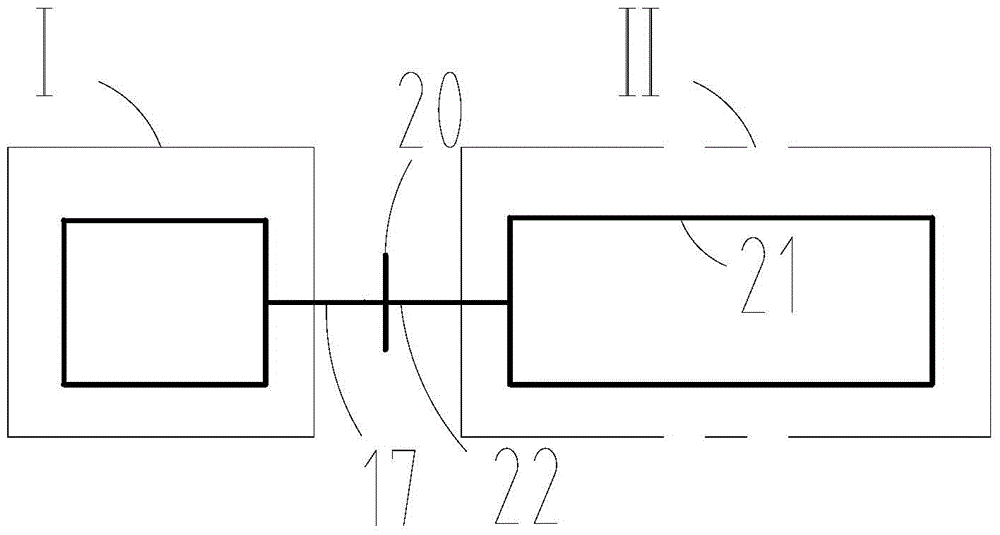

[0066] This embodiment is an extruder formed by a combination of a coaxial output rotation and revolution transmission device and an eccentric rotor volume pulsation deformation plasticization transportation device.

[0067] Wherein, the transmission device I with coaxial output rotation and revolution can adopt the transmission device described in embodiment 1 or embodiment 2. The eccentric rotor volume pulsating deformation and plasticizing transportation device II can adopt the eccentric rotor volume pulsating deformation and plasticizing transportation device disclosed in the patent application with application number 201410206552.8, such as Figure 4 As shown, a stator 21 and a rotor 22 are included.

[0068] Such as image 3 As shown, the transmission device I with coaxial output rotation and revolution is connected with the eccentric rotor volume pulsation deformation plasticization transportation device II through a connecting piece 20 . The power output shaft 17 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com