An indexing device for ultra-precision instruments

A technology for indexing devices and precision instruments, which is applied in the direction of electromechanical devices, transmission devices, supporting machines, etc., can solve the problems of affecting the processing accuracy of ultra-precision instruments, increasing the accuracy level, and huge load-bearing devices, so as to avoid one-time measurement errors, Improved accuracy level and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

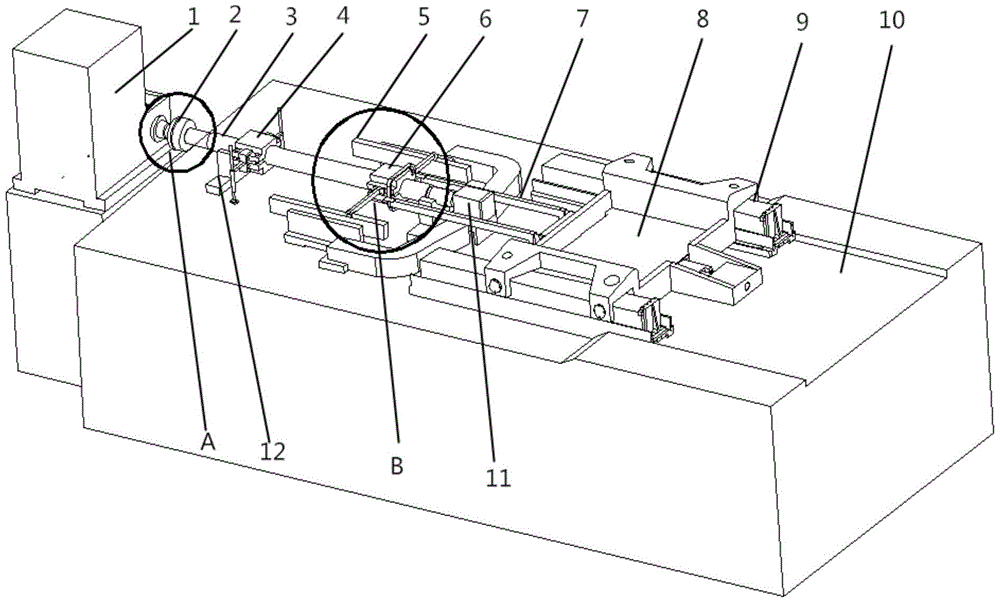

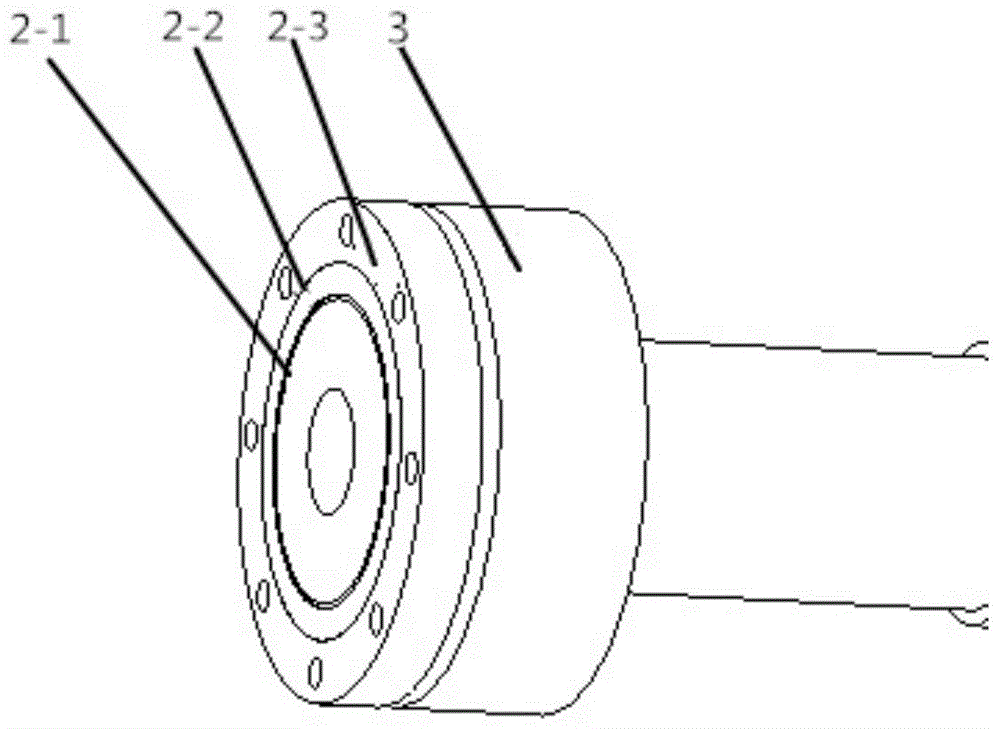

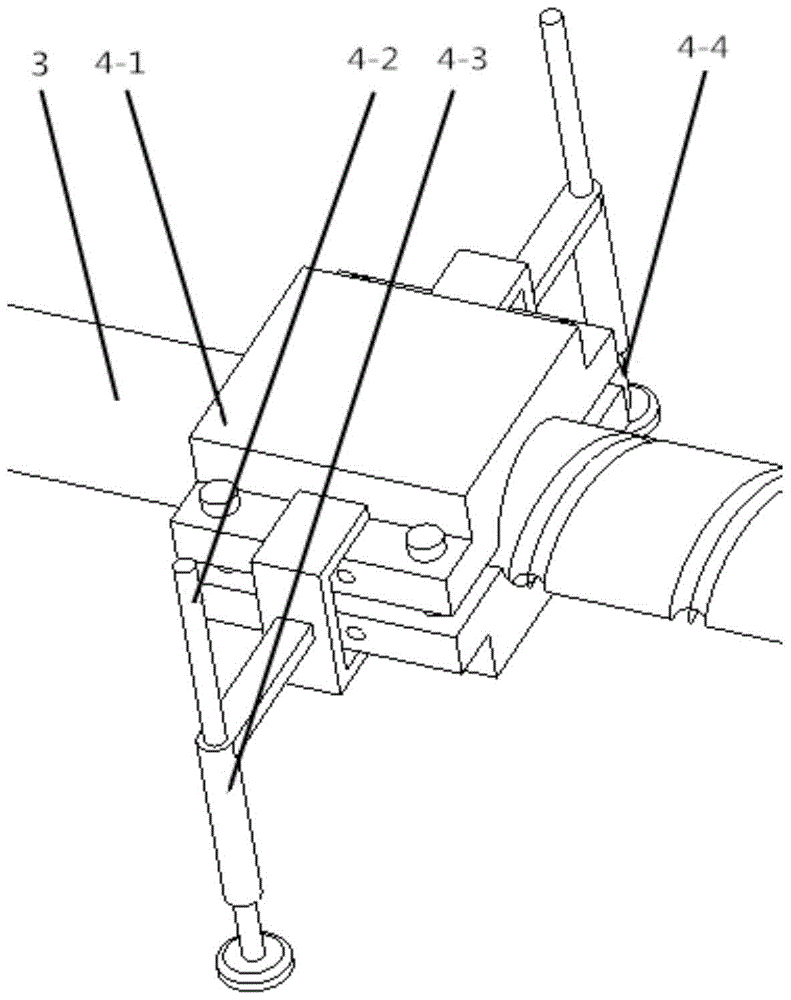

[0031] see Figures 1 to 6 , In this embodiment, an indexing device for ultra-precision instruments is set on the workbench, including: 1 motor, 2 harmonic reducers (2-1 wave generator, 2-2 flexible wheel, 2 -3 rigid wheels), 3 lead screws, 4 load-bearing devices, 5 roller guide rails, 6 opening and closing nut pairs, 7 tie rods, 8 inner and outer table assemblies, 9 guide rail assemblies, 11 indexers and 12 lead screw supports;

[0032] see figure 2 and Image 6 , the output shaft of the motor 1 and the lead screw 3 are connected in series through the harmonic reducer 2, which greatly reduces the error caused by turning the rotary motion into a linear motion; the lead screw support seats are located at both ends of the lead screw 3; A load-bearing device 4 and an opening and closing nut pair 6 are respectively provided between the two ends of the lead screw support bases; an indexer 11 is provided at the front end of the lead screw 3; The opening and closing nut pair 6 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com