Combined incineration device for rotary furnace fire grate

A technology of incineration device and rotary kiln, which is applied in incinerators, combustion methods, combustion types, etc., can solve problems such as unsatisfactory combustion effects, and achieve the effect of improving combustion effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

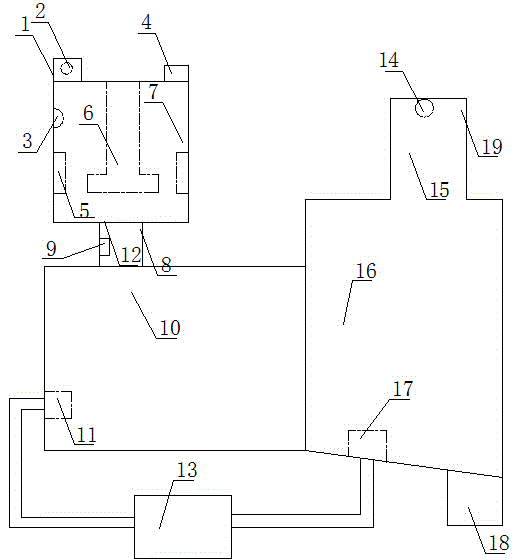

[0015] Such as figure 1 The combined incineration device of a kind of rotary furnace grate comprises a rotary furnace 10, a grate furnace 16 is arranged on one side of the rotary furnace 10, a crushing chamber 7 is arranged at the upper end of the rotary furnace 10, and a crushing device 6 is arranged in the crushing chamber 7, A waste material inlet 1 is arranged on one side of the upper end of the crushing chamber 7, a dryer 5 is arranged in the crushing chamber 7, and a waste material outlet 12 is arranged at the lower end of the crushing chamber 7, and the waste material outlet 12 is connected to the rotary furnace 10 through a connecting pipe 8, and in the rotary furnace 10 A first-level burner 11 is set, a second-level burner 17 is set in the grate furnace 16, an exhaust fan 13 is arranged outside the rotary furnace 10, and the exhaust fan 13 is respectively connected to the first-level burner 11 and the second-level burner 17 through pipelines. The lower end of one side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com