Rapid imaging detection method for gear appearance defect

A technology for image detection and appearance defects, applied in image analysis, image data processing, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

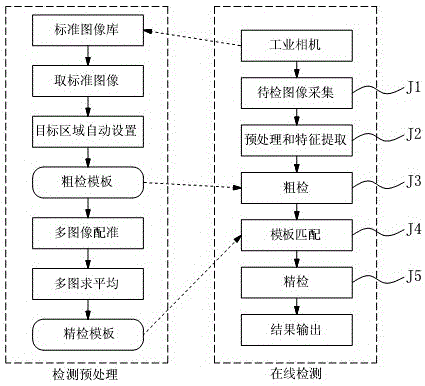

[0054] Referring to the accompanying drawings, the invention's rapid image detection method for gear appearance defects includes two stages of detection preprocessing and online detection.

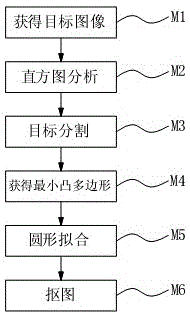

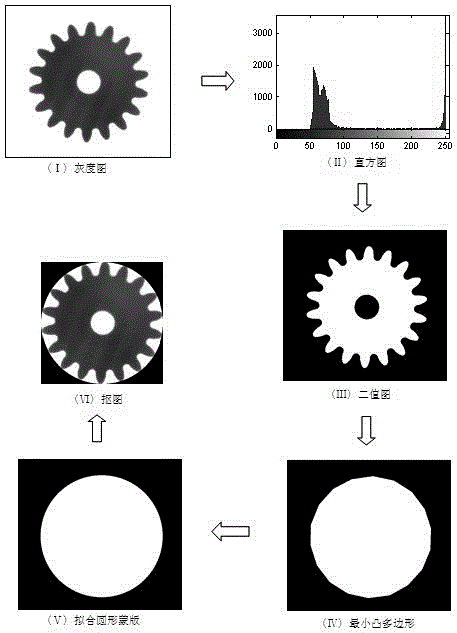

[0055] Referring to the accompanying drawings, the detection preprocessing stage includes three processes of automatic setting of the target area, generation of a rough detection template and generation of a fine detection template. like figure 2 and image 3 As shown, the process of automatically setting the target area specifically includes the following steps:

[0056] Step M1) Take the target gear to obtain the target image;

[0057] Step M2) using an iterative method to analyze the target image histogram to obtain a threshold;

[0058] Step M3) Obtain the binary image of the target image by thresholding segmentation;

[0059] Step M4) Obtain the minimum convex polygon based on the binary image of the target image;

[0060] Step M5) performing curve fitting based on the convex po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com