Manual tobacco mulch film laying machine

A technology of mulching and manpower, which is applied in the direction of digging/covering ditches, agricultural machinery and implements, shovels, etc., and can solve problems such as unfavorable transportation and use, heavy weight and low efficiency of mulching equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

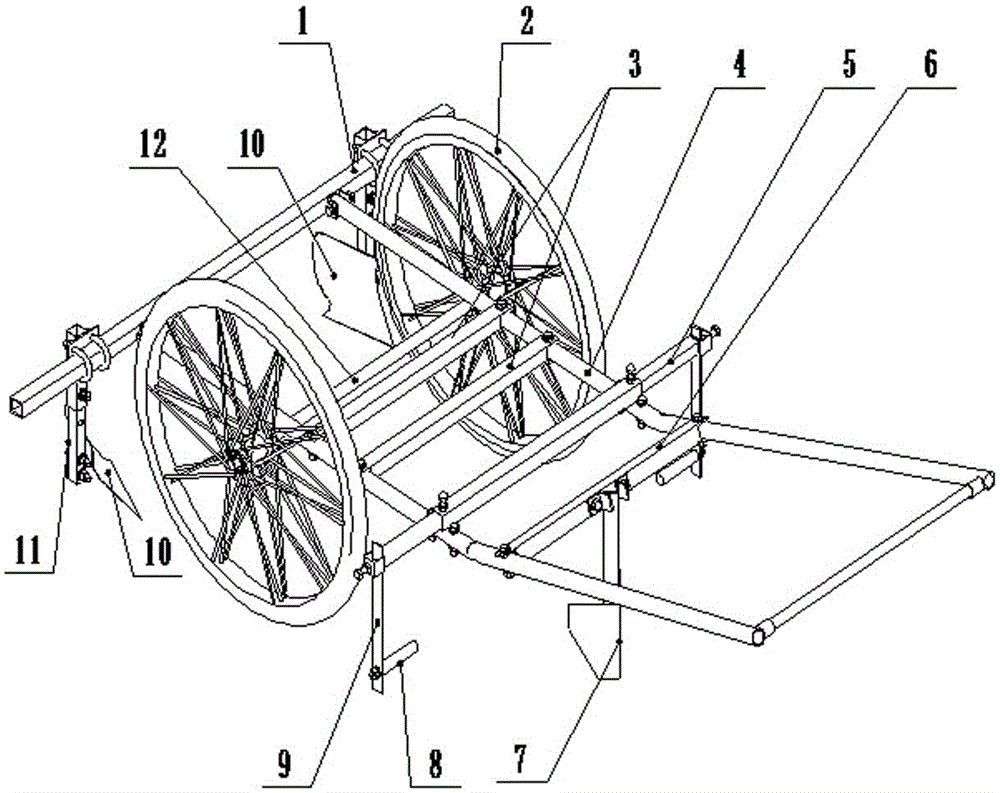

[0017] figure 1 Shown is the structural representation of the manpower tobacco leaf mulching machine of the present invention, will know from the figure, it comprises frame shape manpower handrail bar 4, wheel 2 and wheel shaft 12 thereof; Wherein, the two ends of wheel shaft 12 respectively actuate with wheel 2 Connect, the middle part of frame-shaped human handrail bar 4 is fixedly connected with the two ends of wheel shaft 12 by welding, constitutes the rickshaw of simple structure. At the rear end of both sides of the frame-shaped manpower handrail bar 4, a soil-covering shovel device 1 is fixedly connected with a bolt; The side shovel 10. Above the frame-shaped manpower handrail bar 4 middle parts, the sprayer installation frame 3 is fixedly connected with the frame-shaped manpower handrail bar 4 both sides bars by bolts, and is used to install the sprayer; B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com