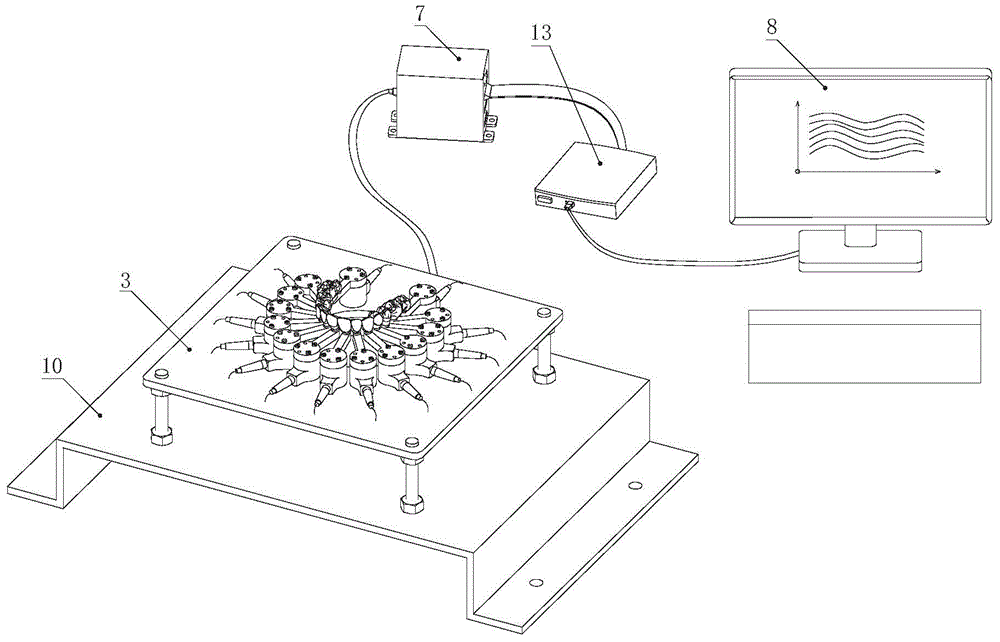

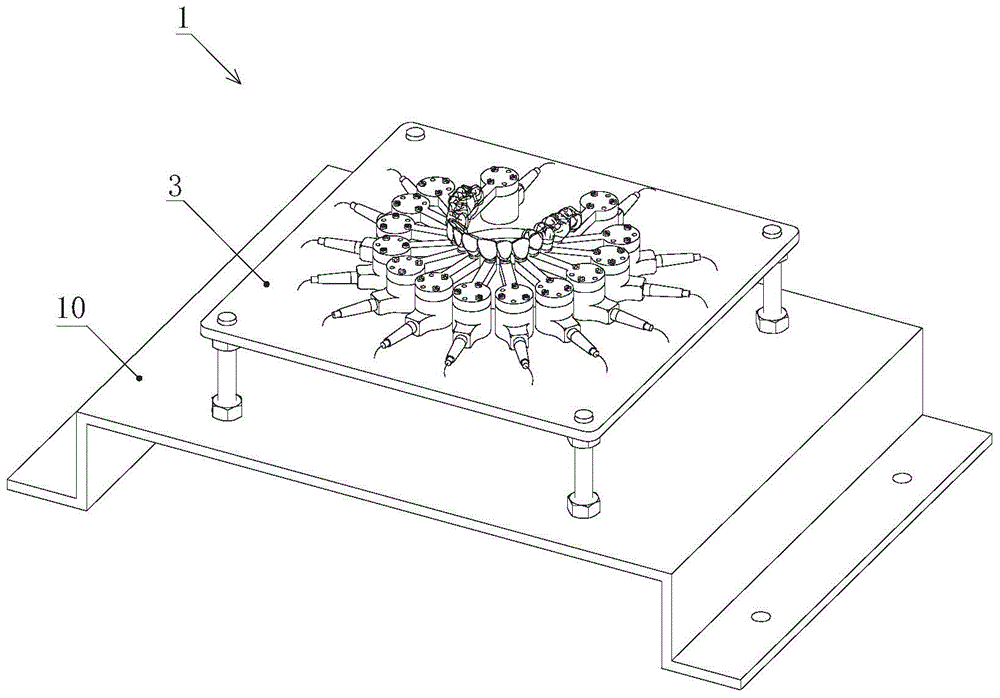

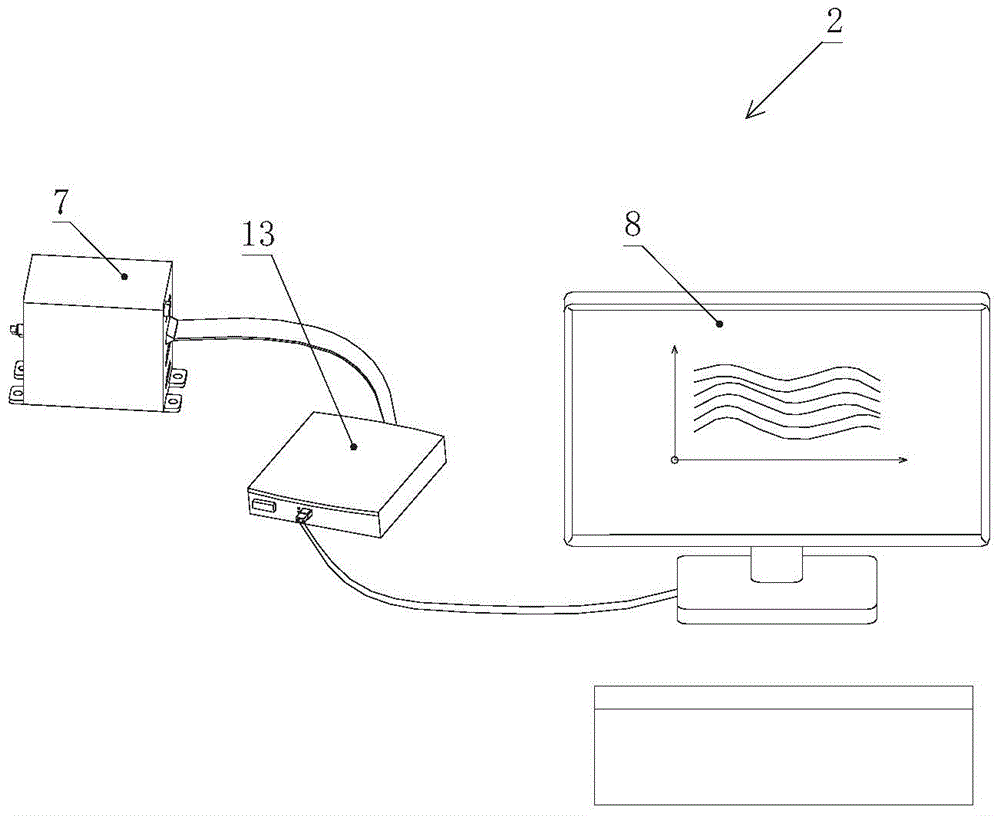

Tooth received-force testing device and method

A technology for testing devices and teeth, applied in dentistry, medical science, etc., can solve problems such as shortages, and achieve the effects of reducing processing errors, improving appliance performance, and improving orthodontic solutions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] The preparation method of the dental crown simulation part 4 will be described in detail below.

[0074] A digital model of the patient's current teeth is first obtained. For example, the state of the dentition arrangement can be obtained by taking an impression, thereby generating a physical dental model, and then performing a three-dimensional scan on the physical dental model to obtain a digital model. It is also possible to directly obtain images of teeth, or teeth and their surrounding tissues by means of optical scanning, X-ray imaging, ultrasonic imaging, three-dimensional photography, three-dimensional imaging, or medical CT scanning, and generate digital models of teeth in a computer. That is, the digital model of each tooth, that is, the digital model of the crown 14 is obtained by digitizing the patient's teeth. Among them, the obtained plaster model can be cut with a knife, saw, or other cutting tools to obtain a physical model of each tooth, and a three-di...

specific Embodiment approach

[0102] Moreover, according to another specific embodiment of the present invention, the force measuring device can also be used to measure the influence of the thickness of the attachment and the appliance on the orthodontic force of the teeth.

[0103] For example, in practical applications, a digital model representing the three-dimensional shape of the invisible aligner can be set so that the thickness of the aligner for each tooth is different; The corresponding thickness of the part of the appliance reduces the rigidity of the part of the appliance and increases the elasticity, so that the teeth are easy to move during the orthodontic process. For the teeth that do not want to move during the orthodontic process, the thickness of the corresponding part of the appliance can be increased, so that the stiffness of the appliance in this part is increased, while the elasticity is reduced, so that the tooth is not easy to move during the orthodontic process. . Correspondingly,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com