Integral-horizontal-moving pure mechanical toggle rod type drawing cushion with permanent magnet synchronous servo motor for double-ended drive

A servo motor, permanent magnet synchronous technology, applied in the field of press stretch pad manufacturing, can solve the problems of large system heat generation, complex electronic control system, high maintenance cost, etc., and achieve high controllable precision, accurate movement, and service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

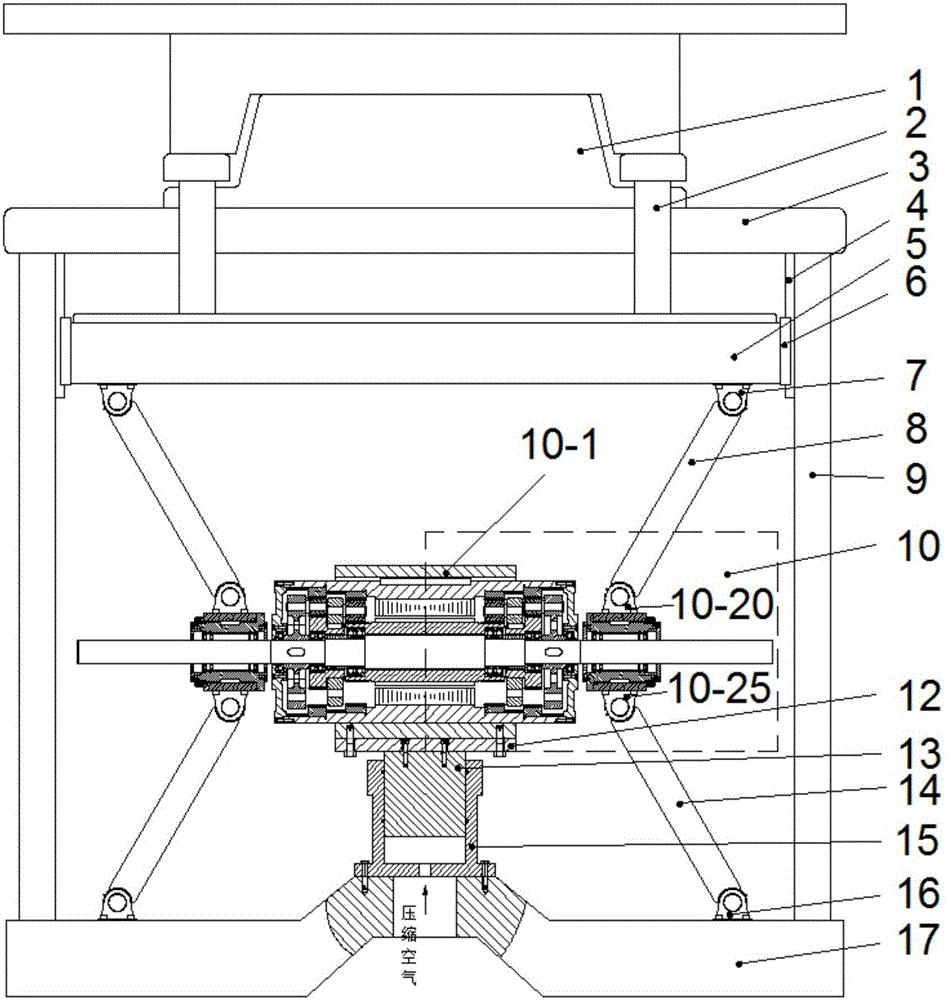

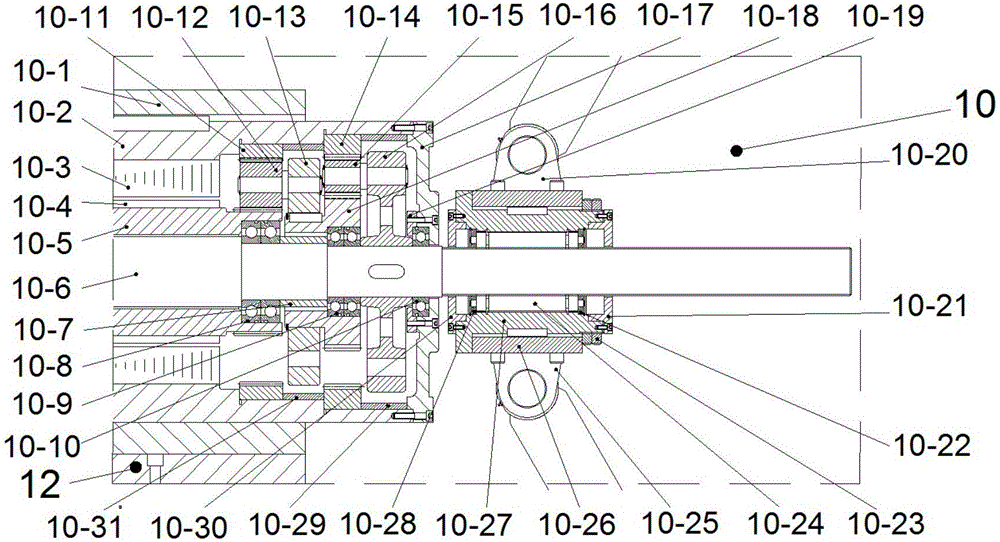

[0011] Such as figure 1 As shown, the purely mechanical toggle-type stretching pad with biaxial extension permanent magnet synchronous servo motor and overall translation is a completely symmetrical structure on the left and right. There are more than two support frames 2 arranged in the circumferential direction of the lower mold 1 as required, the lower end of the support frame 2 passes through the through hole on the workbench 3 and is fixed on the box body 5, and the two ends of the workbench 3 are fixed on the upper end of the column 9 , the left and right sides of the box body 5 are connected with the slider 6, the slider 6 cooperates with the guide rail 4, and slides on the guide rail 4, the guide rail 4 is fixed on the column 9, and the lower end of the column 9 is connected to the base 17, and the box body 5 passes through the first The supporting b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com