Intelligent numerical control machine tool, robot and system

A technology of CNC machine tools and robots, which is applied to automatic control devices, metal processing mechanical parts, measuring/indicating equipment, etc., can solve the problem that the transmission rate cannot keep up with the processing rate, etc., so as to reduce labor intensity and operation preparation time, and reduce occupation. Land area and cost, the effect of saving training fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

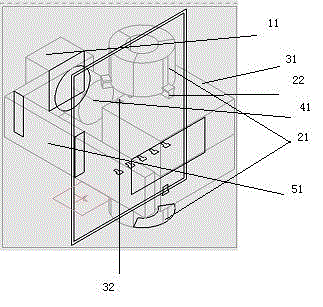

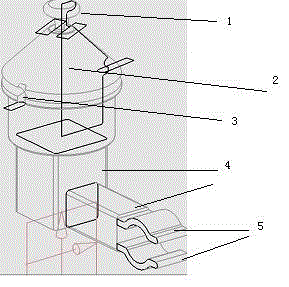

[0020] See Figure 1 to Figure 2, is an intelligent numerical control machine tool, a robot and a system provided in an embodiment of the present invention. In this embodiment, the working platform and the chuck are fixed, and the main shaft moves to realize processing, and the angle rotation device is also installed in the main shaft. When it is used for milling, the robot is installed first, and the workpiece is clamped on the working platform. The device measures the parallelism between the workpiece and the standard axis, and the robot adjusts the angle rotation device so that each reference plane of the workpiece coincides with or is parallel to the reference plane of the machine tool, then determines the origin of the workpiece, sets the coordinate system of the workpiece, changes the tool, and sets the tool length compensation , After transferring or writing the processing program, the processing is completed, the robot is replaced, and the workpiece is inspected. If it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com