A clamping method of a micro-sample clamping device

A clamping device and micro-sample technology, used in workpiece clamping device, preparation of test samples, manufacturing tools, etc., can solve the problems of large linear expansion coefficient, insufficient machining accuracy, and small tightening force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings. Those skilled in the art should understand that the embodiments are only for illustration and do not constitute any limitation to the present invention.

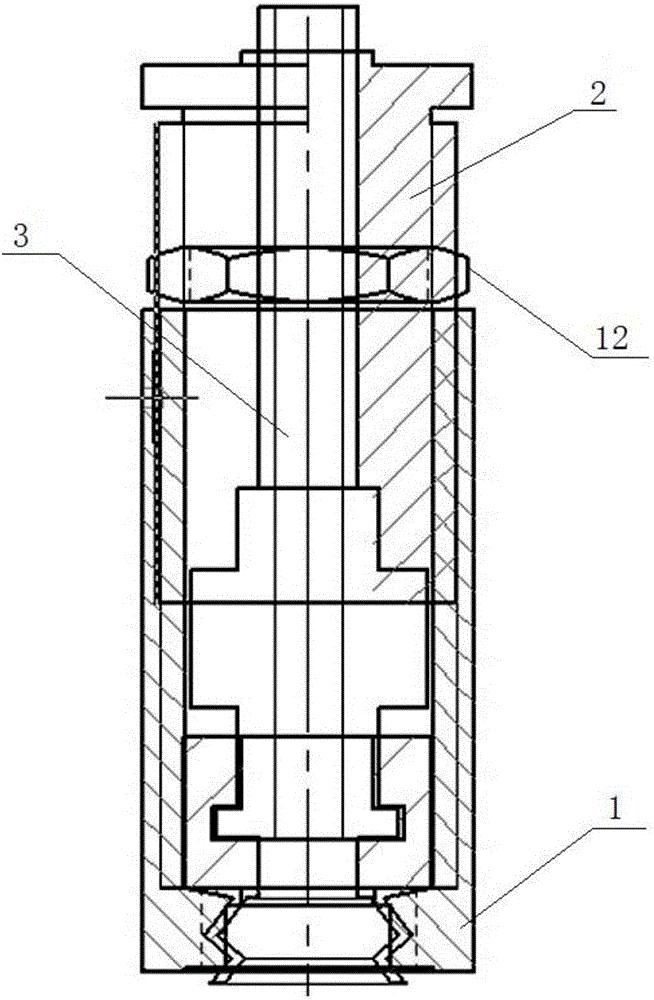

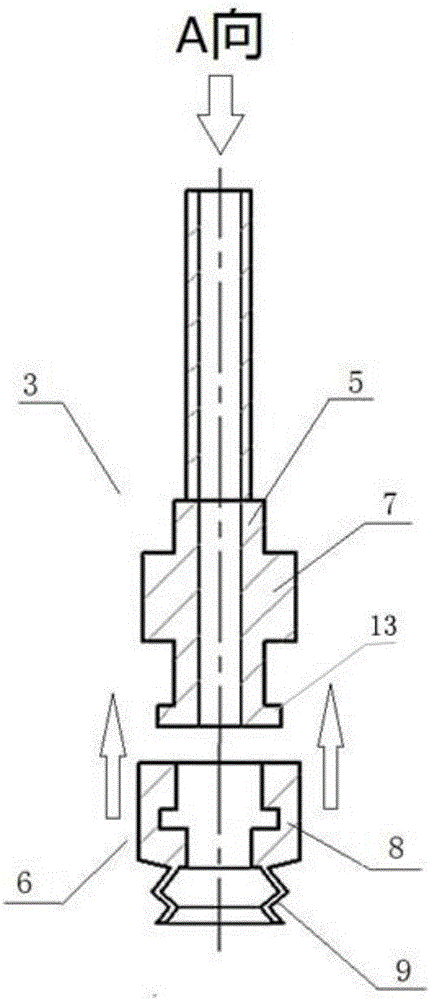

[0055] This embodiment specifically relates to a micro-sample clamping device. The micro-sample clamping device includes an adsorption part, a clamping part, and an adjustment part. After the three parts are assembled, they are connected to a vacuum pump to clamp the micro-sample in the Processing on a grinding machine.

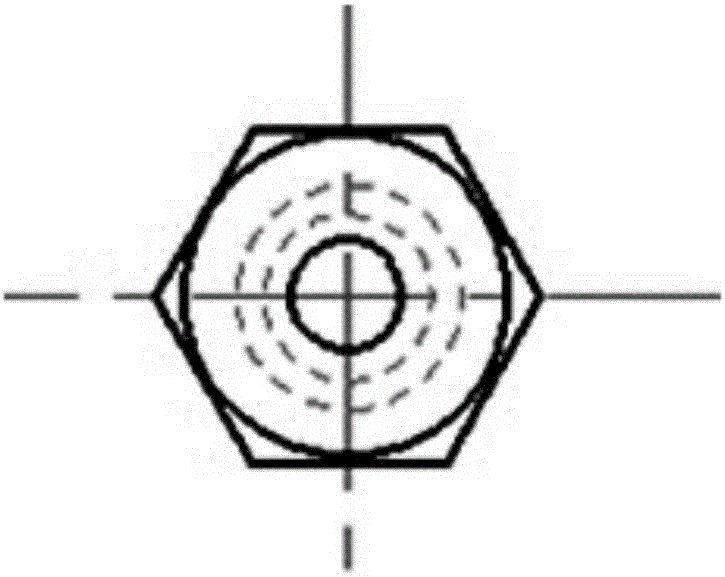

[0056] The adsorption part is composed of a hollow core rod 5, a silica gel suction cup 6 and an air nozzle joint (not shown in the figure). platform 7, and an outer flange 13 is arranged on the bottom edge of its rod body; the silica gel suction cup 6 is specifically composed of a silica gel sleeve 8 and a double-layer suction cup 9, both of which are of an integrated silica gel structure. There is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com