Pneumatic solid particle feeding system

A feeding system and solid particle technology, applied in the direction of conveying bulk materials, loading/unloading, conveyors, etc., can solve the problems of wasting materials, unable to guarantee fluidized materials, short circuit, etc., and achieve the effect of preventing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

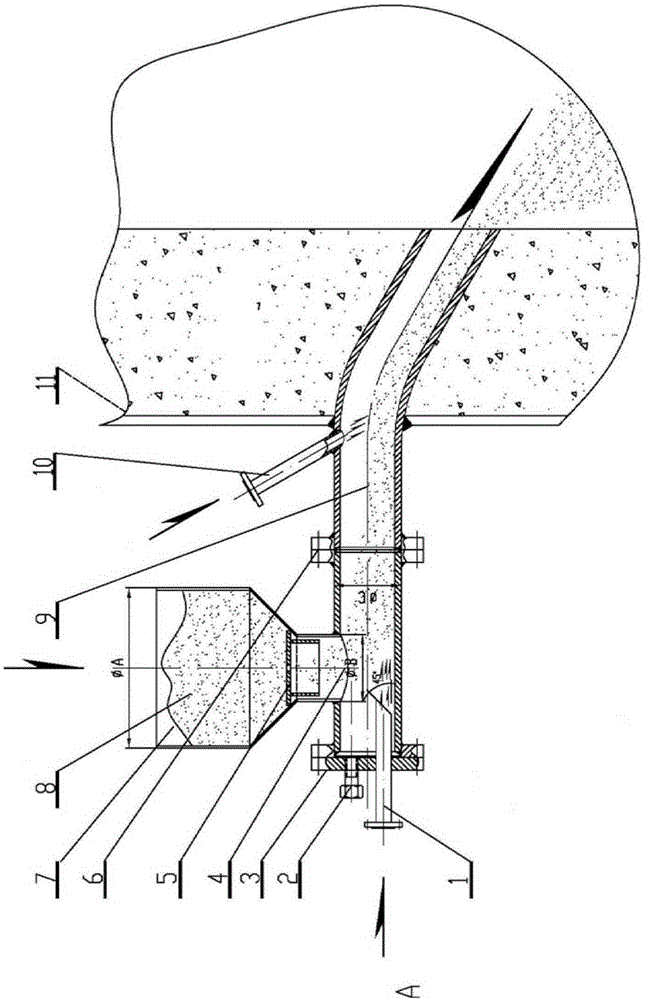

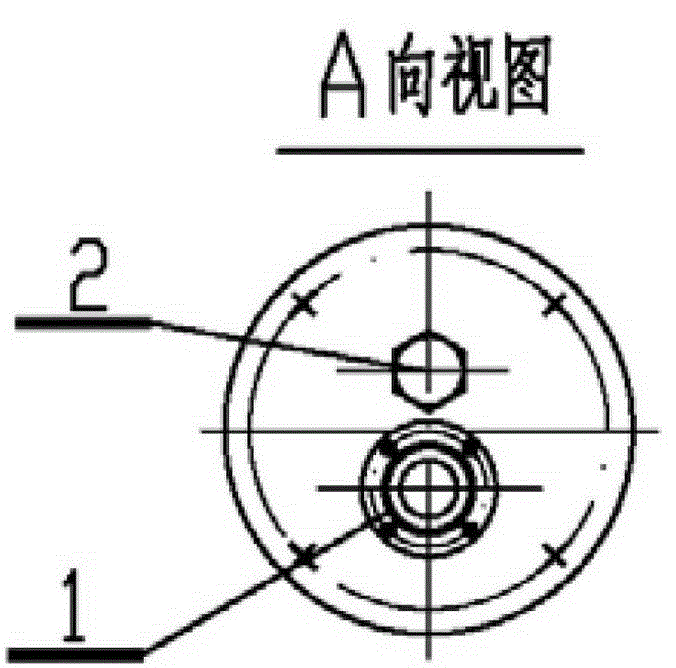

[0049] A solid material particle feeding device of the present invention, wherein the diameter of the feeding pipe 4 is 108 mm, and the diameter of the main blowing pipe 1 is 32 mm. One end of the main blowing pipe 1 is connected to the conveying gas generating device, and the other end extends into the feeding pipe 4 . The center line of the A-direction section of the feeding pipe 4 and the A-direction section of the main air blowing pipe are perpendicular to the horizontal line and the distance between the center line of the two centers is equal to the diameter radius of the feeding pipe 4 and the diameter radius of the main air blowing pipe 1. Poor, that is, the distance between the two centers of the center line is equal to 38mm. Wherein the main blowing pipe 1 extends into the part of the feeding pipe 4, the front end of the air outlet is flush with the side of the feeding port of the hopper 7 near the end of the feeding pipe 4. The plane where the end slit of the air ou...

Embodiment 2

[0051] Another solid material feeding device of the present invention, wherein the diameter of the feeding pipe 4 is 100 mm, and the diameter of the main blowing pipe 1 is 30 mm. One end of the main blowing pipe 1 is connected to the conveying gas generating device, and the other end extends into the feeding pipe 4 . The center line of the A-direction section of the feed pipe 4 and the A-direction section of the main blowing pipe are perpendicular to the horizontal line and the distance between the centerlines of the two centers is less than the difference between the radius of the feed pipe 4 and the main blowing pipe 1 radius. In this embodiment, the distance between the two centerlines is 30mm. Wherein the main blowing pipe 1 extends into the part of the feeding pipe 4, the front end of the air outlet is flush with the side of the feeding port of the hopper 7 near the end of the feeding pipe 4. The end cutout plane of the air outlet of the main blowing pipe 1 forms an angl...

Embodiment 3

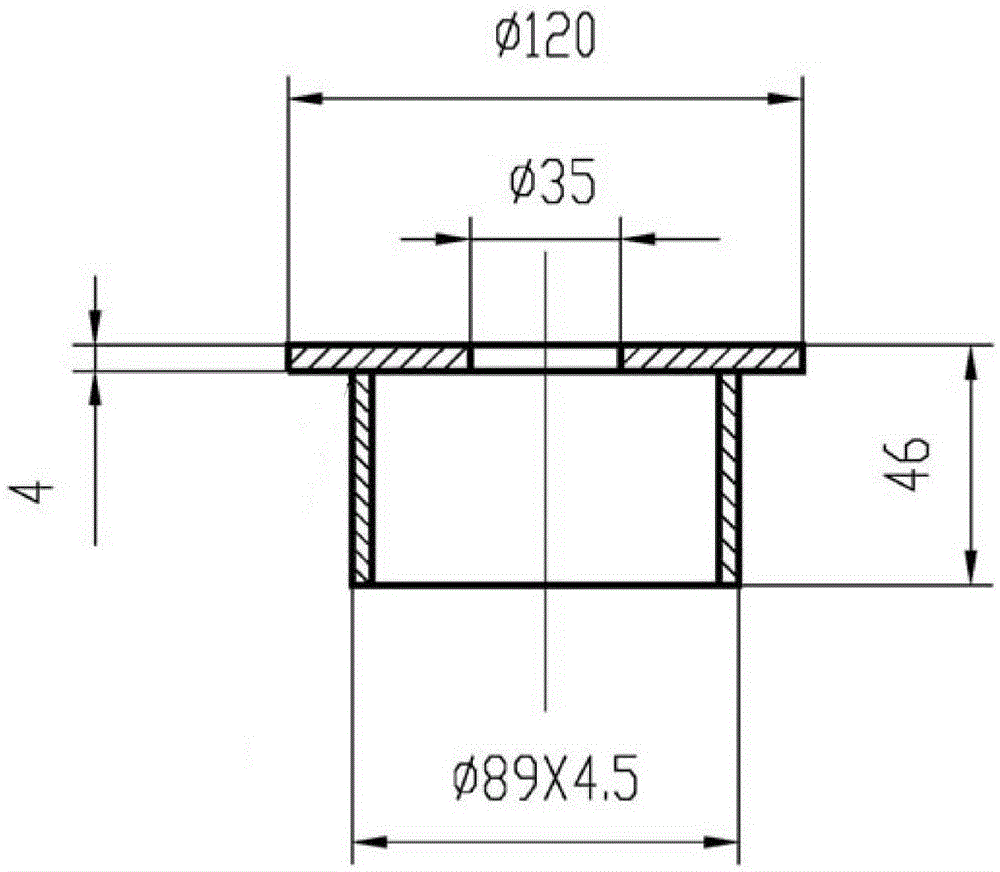

[0053] Another solid material feeding device of the present invention, wherein the diameter of the feeding pipe 4 is 120 mm, and the diameter of the main blowing pipe 1 is 40 mm. One end of the main blowing pipe 1 is connected to the conveying gas generating device, and the other end extends into the feeding pipe 4 . The center line of the A-direction section of the feed pipe 4 and the A-direction section of the main blowing pipe are perpendicular to the horizontal line and the distance between the centerlines of the two centers is less than the difference between the radius of the feed pipe 4 and the main blowing pipe 1 radius. In this embodiment, the distance between the centerlines is 35 mm. Wherein the main blowing pipe 1 extends into the part of the feeding pipe 4, the front end of the air outlet is flush with the side of the feeding port of the hopper 7 near the end of the feeding pipe 4. The plane of the cutout at the end of the air outlet of the main blowing pipe 1 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com