Nano-structure and preparation method thereof

A nano-structure, cone-shaped technology, applied in the nano field, can solve the problems of difficult to achieve large-scale commercial production and high production costs, and achieve the effects of large roughness, strong controllability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

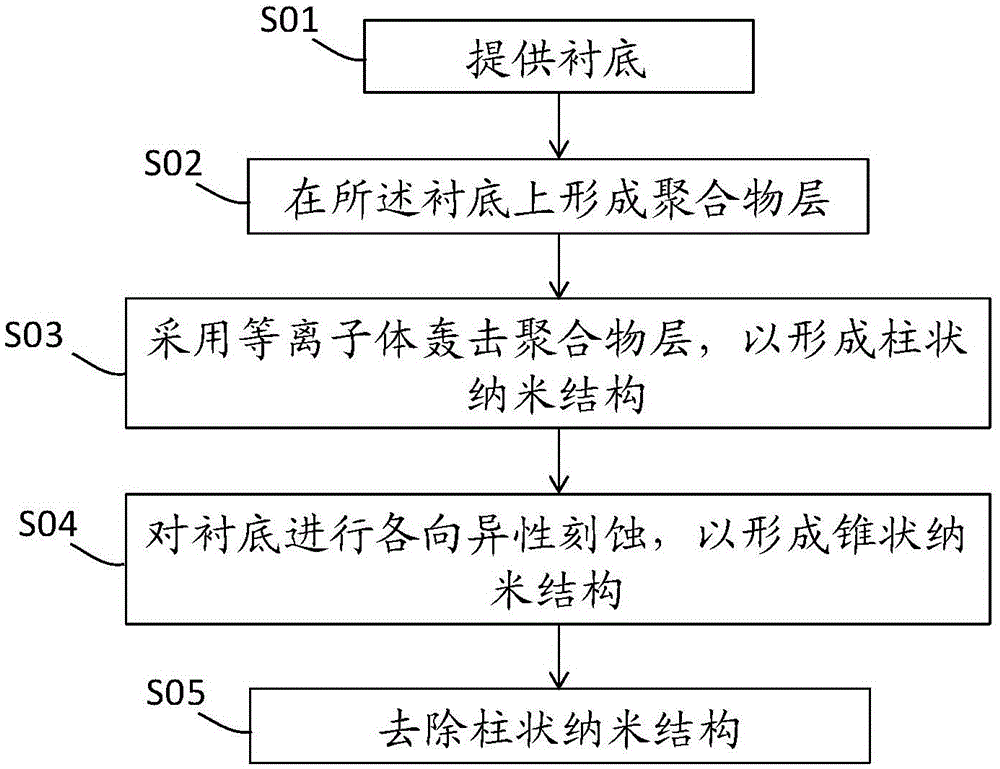

[0034] The invention provides a method for preparing a nanostructure, referring to figure 1 As shown, comprising: providing a substrate; forming a polymer layer on the substrate; bombarding the polymer layer with plasma to form a columnar nanostructure; using the columnar nanostructure as a mask, anisotropically etching the substrate , to form cone-like nanostructures; remove columnar nanostructures.

[0035] In the preparation method of the present invention, plasma technology is used to bombard the polymer layer. During the bombardment process, the product produced by the bombardment polymer will polymerize again to form a columnar nanostructure, and then further anisotropy of the substrate Etching to form a cone-shaped nanostructure, which has a large surface area and surface-to-volume ratio, and has a large roughness, optical absorption characteristics, and plasmonic oscillation enhancement effect, which can be widely used. At the same time , the method has a simple proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com