Post-denitrification operation method based on moving bed biofilm reactors (MBBRs)

A post-denitrification and operation method technology, applied in the field of post-denitrification operation based on MBBR, can solve the problems of accumulation of toxic and harmful substances, influence of toxic and harmful substances, deterioration of biofilm on fillers, etc., and achieve strong tolerance , to avoid microbial inactivation, strong lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The winter secondary effluent of a certain urban sewage treatment plant is used as the influent water, with a water volume of 0.8m 3 / h, water temperature 10-14°C, average pH 6.90, nitrate nitrogen concentration in water 30-40mg / L, hardness 300-350mgCaCO 3 / L. Single reactor volume 1.44m 3 , a total of two reactors are arranged in series, which are respectively the first reactor R1 and the third reactor R3. The specific surface area of the suspended filler used is 620m 2 / m 3 , the filling rate is 50%, and the specific gravity before filming is 0.95. Sodium acetate is added to the influent to supplement the carbon source required for denitrification.

[0033] When the operation started, the operation sequence was not adjusted, and the influent water flowed through the reactors R1 and R3 in sequence. 30 days after the operation started, the average load of the reactor R1 was 0.50kgN / (m 3 d), the average load of reactor R3 is 0.10kgN / (m 3d) The average TN concent...

Embodiment 2

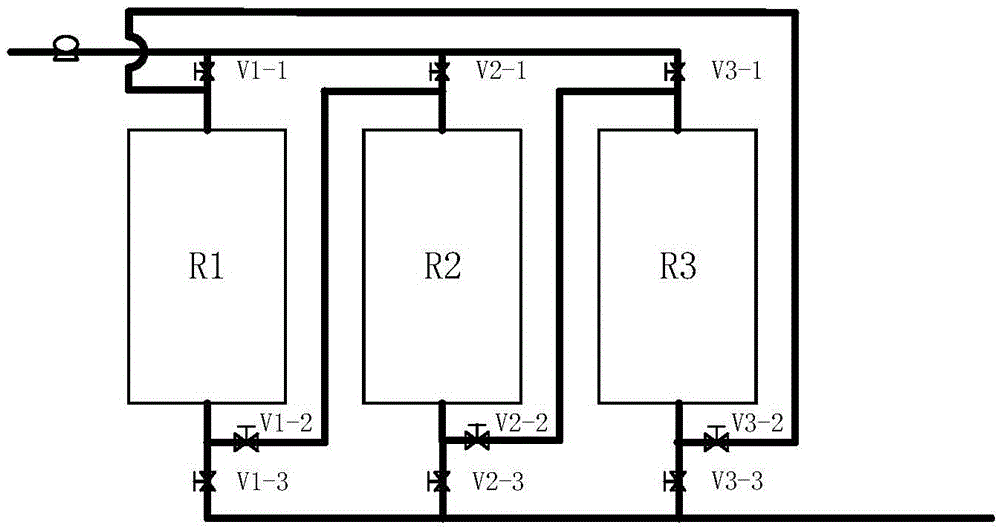

[0035] The secondary effluent of a sewage treatment plant in summer is used as the influent, with a water volume of 1.2m 3 / h, water temperature 22-28°C, average pH 6.97, nitrate nitrogen concentration in water 60-65mg / L, hardness 300-350mgCaCO 3 / L. Single reactor volume 1.44m 3 , a total of three reactors are arranged in series, namely the first reactor R1, the second reactor R2, and the third reactor R3. The specific surface area of the suspended filler used is 800m 2 / m 3 , the filling rate is 40%, the specific gravity before the film is 0.95, and sodium acetate is added to the influent water to supplement the carbon source required for denitrification;

[0036] At the beginning of operation, the order of water flow is R1, R2, R3. After 22 days of operation, the filler film is mature, and the beginning of 8 days is a cycle, and the order of operation is adjusted every cycle. The order of water flow in each cycle is R1. , R2, R3, R3, R1, R2, R2, R3, R1, and then rest...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com