Antimony-based compound flame retardant for silicate fiberboard and preparation method thereof

A technology of composite flame retardant and fiberboard, which is applied in the fields of chemical industry and materials, can solve problems such as heavy weight and limited application range, and achieve the effects of increasing production efficiency, improving fire resistance and processing performance, and reducing the amount of antimony used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

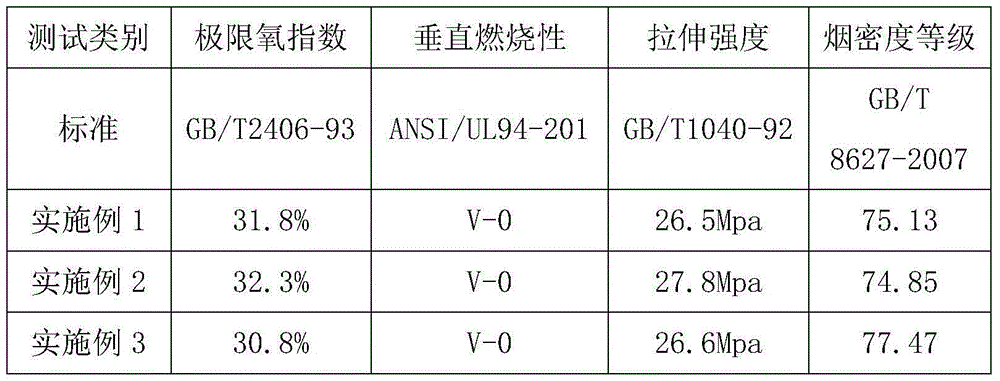

Examples

Embodiment 1

[0020] Based on the total weight, weigh 50 parts of antimony trioxide, 30 parts of calcium silicate, 10 parts of zinc borate, 10 parts of hydrotalcite, and 5 parts of modifier.

[0021] The preparation method of antimony series composite flame retardant of the present invention comprises the following steps:

[0022] S1. Antimony trioxide modification: use titanate or aluminate to modify the surface of antimony trioxide, the modification temperature is 140°C, the stirring rate is 4000rpm / min, and the stirring time is 3.5h;

[0023] S2. Raw material mixing: put the modified antimony trioxide, calcium silicate, hydrotalcite, and zinc borate in the frequency conversion mixer for low-speed and high-speed two-stage uniform mixing. The stirring speed of low-speed mixing is 1200rpm / min, the mixing time is 5min, and the temperature is not controlled; the stirring speed of high-speed mixing is 5000rpm / min, the temperature is controlled at 100°C, and the mixing time is 20min;

[0024] ...

Embodiment 2

[0026] In total weight, 60 parts of antimony trioxide, 30 parts of calcium silicate, 4 parts of zinc borate, 3 parts of hydrotalcite, and 3 parts of modifier.

[0027] The preparation method of antimony series composite flame retardant of the present invention comprises the following steps:

[0028] S1. Antimony trioxide modification: use titanate or aluminate to modify the surface of antimony trioxide, the modification temperature is 100°C, the stirring rate is 2000rpm / min, and the stirring time is 4.5h;

[0029] S2. Raw material mixing: put the modified antimony trioxide, calcium silicate, hydrotalcite, and zinc borate in the frequency conversion mixer for low-speed and high-speed two-stage uniform mixing. The stirring speed of low-speed mixing is 600rpm / min, the mixing time is 10min, and the temperature is not controlled; the stirring speed of high-speed mixing is 2000rpm / min, the temperature is controlled at 70°C, and the mixing time is 40min;

[0030] S3. Screening: tran...

Embodiment 3

[0032] Based on the total weight, there are 60 parts of antimony trioxide, 20 parts of calcium silicate, 10 parts of zinc borate, 5 parts of hydrotalcite and 5 parts of modifier.

[0033] The preparation method of antimony series composite flame retardant of the present invention comprises the following steps:

[0034] S1. Antimony trioxide modification: use titanate or aluminate to modify the surface of antimony trioxide, the modification temperature is 120°C, the stirring rate is 3000rpm / min, and the stirring time is 4h;

[0035] S2. Raw material mixing: put the modified antimony trioxide, calcium silicate, hydrotalcite, and zinc borate in the frequency conversion mixer for low-speed and high-speed two-stage uniform mixing. The stirring speed of low-speed mixing is 900rpm / min, the mixing time is 8min, and the temperature is not controlled; the stirring speed of high-speed mixing is 3500rpm / min, the temperature is controlled at 85°C, and the mixing time is 30min;

[0036] S3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com