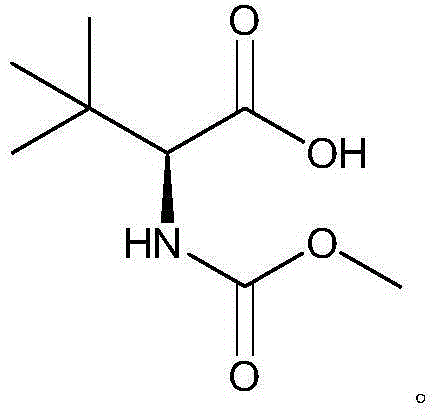

Preparation method of N- methoxycarbonyl group-L-tertiary leucine

A technology of tertiary leucine and tertiary leucine amine salt, applied in the field of medicine and chemical industry, can solve the problem of large-scale industrial production of unsuitable MOC-L-tertiary leucine, difficulty in separation and extraction of L-tertiary leucine, and high cost problem, to achieve the effect of low cost, high product purity, simple and reasonable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

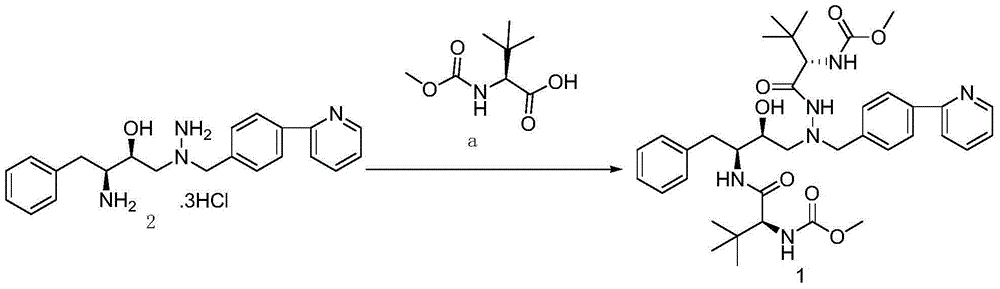

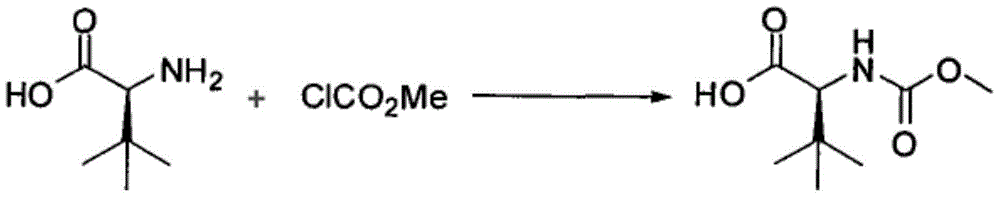

Method used

Image

Examples

Embodiment 1

[0050] Add 765 g of ethyl acetate into a 1000 ml reaction flask, add 100 g of N-methoxycarbonyl-tert-leucine while stirring, and heat to 50-60°C. Stir to completely dissolve, add 66.7g of D-α-phenylethylamine, after the dropwise addition, keep warm for 10 minutes, cool down until the material precipitates, keep warm for 1 hour, then cool down to 0-5°C, keep warm for 1 hour, and filter with suction to get the wet product .

[0051] Add 240g of the above wet product into a 2000ml bottle, add 750g of water, stir to dissolve, and cool to 0-10°C. Add liquid alkali water dropwise to adjust the pH to about 11, extract with 1200ml toluene, wash the toluene layer with 300g water once, recover D-α-phenylethylamine from the toluene layer, pump 500g ethyl acetate into the water layer, cool to 0-5°C, Use hydrochloric acid to adjust the pH to 1~3, control the temperature not to exceed 10°C, separate layers, add 100g of anhydrous magnesium sulfate to the organic layer and dry for 2 hours, f...

Embodiment 2

[0053] Add 765g of acetone into a 1000ml reaction flask, add 100g of N-methoxycarbonyl-tert-leucine while stirring, and heat to 40-45°C. Stir to completely dissolve, add 66.7kg of D-α-phenylethylamine, after the dropwise addition, keep warm for 10 minutes, cool until the material precipitates and keep warm for 1 hour, then cool down to -5°C to 0°C, keep warm for 1 hour, and filter with suction to get Wet product.

[0054] Add 120g of the above wet product into a 1000ml bottle, add 400g of water, stir to dissolve, and cool to 0-10°C. Add liquid alkali water dropwise to adjust the pH to about 11, extract with 600ml toluene, wash the toluene layer with 150g water once, recover D-α-phenylethylamine from the toluene layer, pump 300g ethyl acetate into the water layer, cool to 0-5°C, Use hydrochloric acid to adjust the pH to 1~3, control the temperature not to exceed 10°C, separate layers, put 50g of anhydrous magnesium sulfate into the organic layer and dry for 2 hours, filter wit...

Embodiment 3

[0056] Add 600 g of isopropanol and 50 g of water into a 1000 ml reaction flask, add 100 g of N-methoxycarbonyl-tert-leucine while stirring, and heat to 45-50°C. Stir to completely dissolve, add 66.7kg of D-α-phenylethylamine, after the dropwise addition, keep warm for 10 minutes, cool until the material precipitates and keep warm for 1 hour, then cool down to -5°C to 0°C, keep warm for 1 hour, and filter with suction to get Wet product.

[0057] Add 60g of the above wet product into a 500ml bottle, add 200g of water, stir to dissolve, and cool to 0-10°C. Add liquid alkali water dropwise to adjust the pH to about 11, extract with 300ml toluene, wash the toluene layer with 80g water once, recover D-α-phenylethylamine from the toluene layer, pump 200g ethyl acetate into the water layer, cool to 0-5°C, Use hydrochloric acid to adjust the pH to 1~3, control the temperature not to exceed 10°C, separate layers, add 20g of anhydrous magnesium sulfate to the organic layer and dry for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com