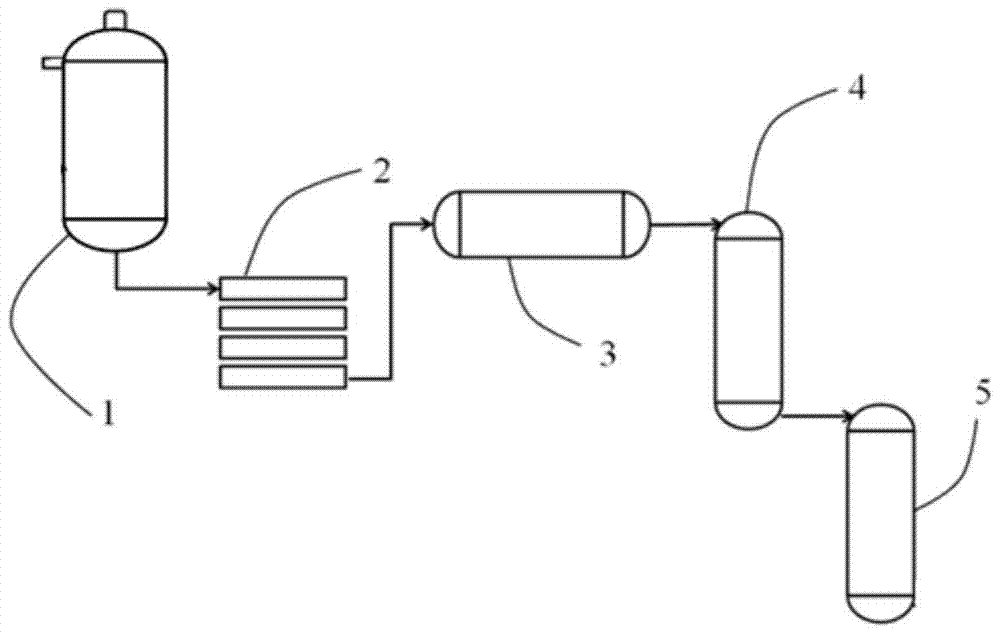

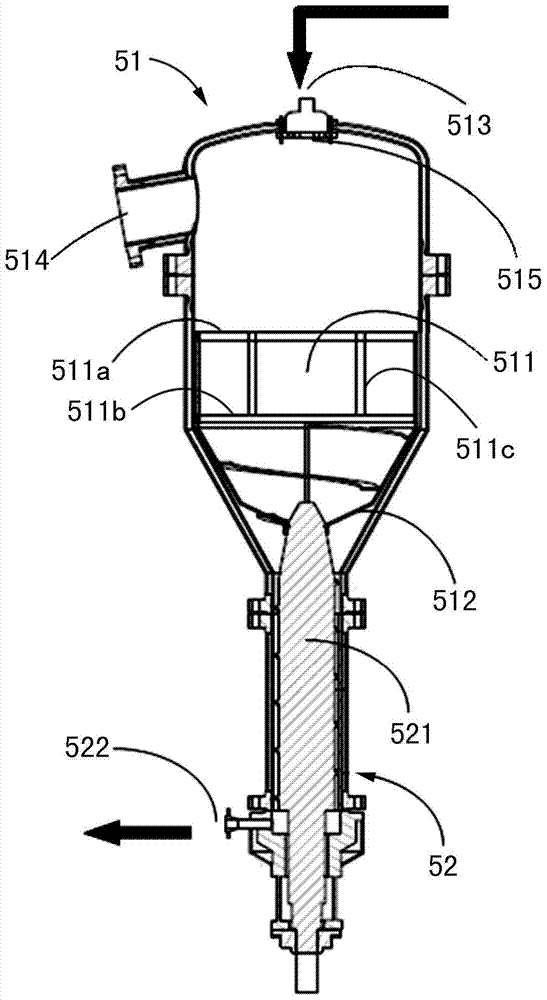

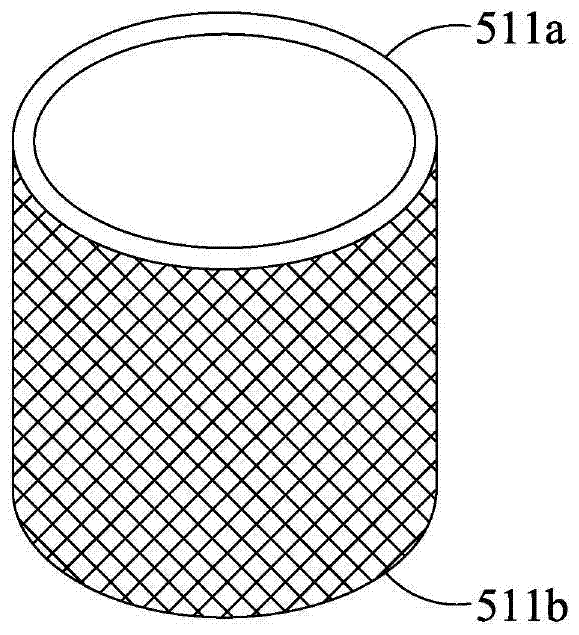

A device for preparing polyamide 5x, a final polymerization method, and production equipment and methods for polyamide 5x

A polyamide and final polymerization device technology, applied in chemical instruments and methods, chemical/physical/physicochemical processes, chemical/physical processes, etc., can solve problems such as after-condenser description, achieve good molecular weight uniformity, gas-liquid Good separation effect and enhanced stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] Configuration pH is the 56 salt solution of 65% concentration of 7.95, carries out polymerization by the condition of table 1 through the production equipment of described polyamide 5X, and kettle body pressure is 210mmHgA, obtains the slice that relative viscosity is 68.9, and its terminal amino content is 40.4.

Embodiment 2

[0091] Configuration pH is the 56 salt solution of 65% concentration of 8.05, carries out polymerization according to the condition of implementing 1 through the production equipment of described polyamide 5X, but the pressure of still body is adjusted to 180mmHg A, and output improves 20% compared with embodiment 1 %, to obtain slices with a relative viscosity of 69.7 and an amino group content of 40.1.

Embodiment 3

[0093] Except that the pressure in the still body was changed to 216mmHgA, other conditions were the same as in Example 2, and the output was also the same. The relative viscosity obtained was 56.1 slices, and its amino terminal content was 42.6.

[0094] Table 1 shows the relevant experimental data of prepared PA56 (polyamide 56):

[0095] Table 1

[0096]

[0097]

[0098] Unless otherwise defined, the terms used in the present invention have meanings commonly understood by those skilled in the art.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com