Preparation method for nickel-plated carbon nano tube reinforced aluminum matrix composites

A technology of nickel-plated carbon nanotubes and composite materials, applied in the field of metal composite materials, to achieve the effect of improving mechanical properties, simple process, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing a nickel-plated carbon nanotube reinforced aluminum matrix composite material, the steps comprising:

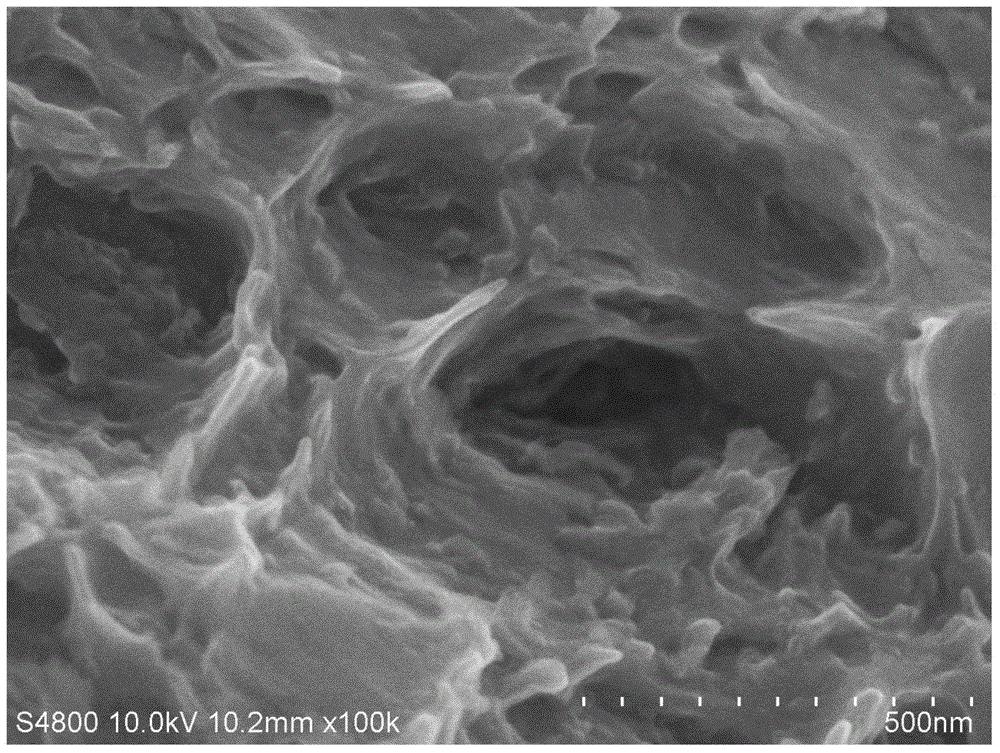

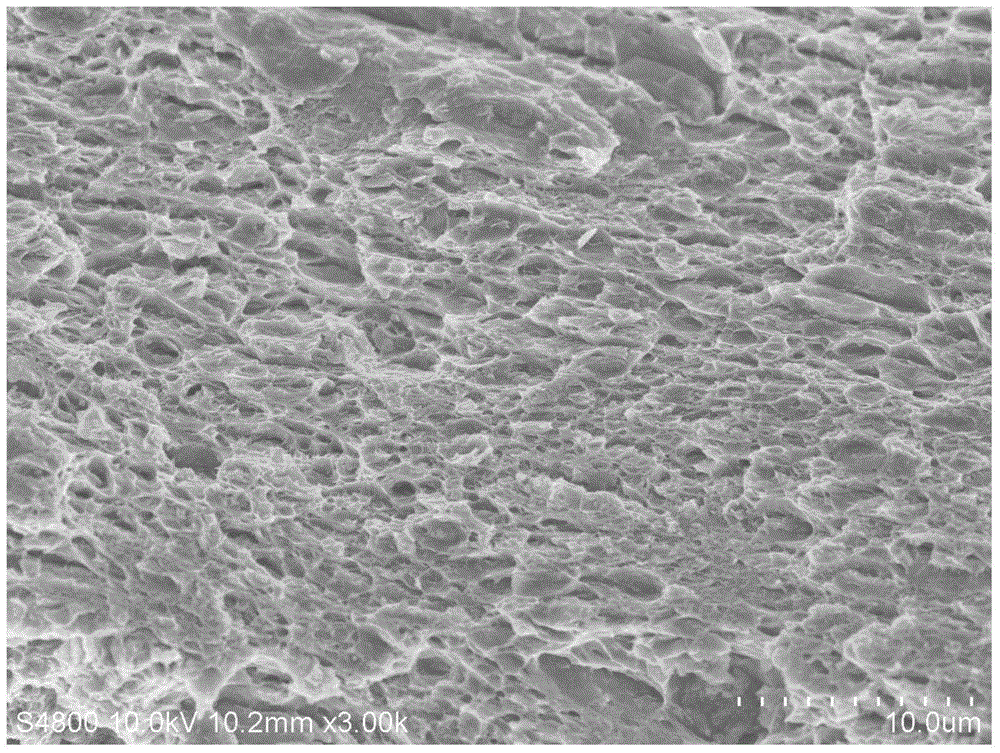

[0026] (1) Put the multi-wall carboxylated carbon nanotubes with a diameter of 100nm into NiSO with a concentration of 0.2mol / L 4 Soak in the solution for 10min to allow the surface of carboxylated carbon nanotubes to absorb Ni 2+ , rinse with deionized water after soaking; absorb Ni on the surface 2+ carbon nanotubes into 0.4mol / L of KBH 4 In the solution, in an ultrasonic dispersion environment, reduce for 20 minutes, reduce the adsorbed nickel ions to nickel simple substance, and then wash with deionized water; put the carbon nanotubes with nickel simple substance into the solution containing NiSO 4 ·6H 2 O25g / L, NaHPO 2 ·H 2 O20g / L, Na 2 C 6 h 5 o 7 2H 2 020g / L, NaAc (anhydrous) 5g / L, pH is in the beaker of 200ml of 6.0, is placed in 80 ℃ of constant-temperature oil baths, and plating 30min obtains the carbon nanotube of nickel coat...

Embodiment 2

[0031] A method for preparing a nickel-plated carbon nanotube reinforced aluminum matrix composite material, the steps comprising:

[0032] (1) Put the multi-walled carboxylated carbon nanotubes with a diameter of 80nm into NiCl with a concentration of 0.1mol / L 2 Soak in the solution for 30min to allow the surface of carboxylated carbon nanotubes to absorb Ni 2+ , rinse with deionized water after soaking; absorb Ni on the surface 2+ carbon nanotubes into 4mol / L KBH 4 In the solution, in an ultrasonic dispersion environment, reduce for 20 minutes, reduce the adsorbed nickel ions to nickel simple substance, and then wash with deionized water; put the carbon nanotubes with nickel simple substance into the solution containing NiCl 2 ·6H 2 O25g / L, NaHPO 2 ·H 2 O20g / L, Na 2 C 6 h 5 o 7 2H 2 020g / L, NaAc (anhydrous) 5g / L, pH is in the beaker of 200ml of 6.0, is placed in 80 ℃ of constant-temperature oil baths, and plating 30min obtains the carbon nanotube of nickel coating;...

Embodiment 3

[0037]A method for preparing a nickel-plated carbon nanotube reinforced aluminum matrix composite material, the steps comprising:

[0038] (1) Put the multi-walled carboxylated carbon nanotubes with a diameter of 150nm into NiSO with a concentration of 0.8mol / L 4 Soak in the solution for 20min to allow the surface of carboxylated carbon nanotubes to absorb Ni 2+ , rinse with deionized water after soaking; absorb Ni on the surface 2+ carbon nanotubes into 1mol / L KBH 4 In the solution, in an ultrasonic dispersion environment, reduce for 15 minutes, reduce the adsorbed nickel ions to simple nickel, and then wash with deionized water; put the carbon nanotubes with simple nickel into the solution containing NiSO 4 ·6H 2 O25g / L, NaHPO 2 ·H 2 O20g / L, Na 2 C 6 h 5 o 7 2H 2 020g / L, NaAc (anhydrous) 5g / L, pH is in the beaker of 200ml of 6.0, is placed in 80 ℃ of constant-temperature oil baths, and plating 30min obtains the carbon nanotube of nickel coating;

[0039] (2) be th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com