Benzimidazoline corrosion inhibitor prepared from refined swill-cooked dirty oil

A technology of benzimidazoline and corrosion inhibitor, which is applied in the field of benzimidazoline corrosion inhibitor, to achieve the effect of increasing metal corrosion resistance, increasing hydrophobicity, and reducing metal corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

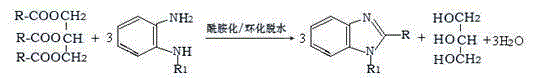

Method used

Image

Examples

Embodiment 1

[0030] In a three-necked flask equipped with a water separator, a thermometer, a condenser and a stirring device, add 20g of refined waste oil, 25.0g O-phenylenediamine and 60ml of xylene, feed nitrogen, slowly heat to 140°C, react for 3.5-4.0h, gradually raise the temperature to 150-160°C, after the xylene solvent is evaporated, remove the water separator, change to a vacuum distillation device, and control the pressure Under 200mmHg, stir and react at 175-180°C for 2-2.5h, water and excess reactants are continuously evaporated, then the system pressure gradually drops to 20mmHg, and then continue to react at constant temperature for 1.0-1.5h until the reaction During the process, until no low-boiling point liquid evaporates, after the product is cooled, add 80ml of 10% NaCl aqueous solution to the mixed product and stir evenly, heat the mixture to 80°C and keep it warm for 1h, cool and stand for 2.5h, and separate with a separatory funnel The oil in the upper layer was washe...

Embodiment 2

[0032] Add 30g of refined waste oil, 39g of N-methyl-o-phenylenediamine and 70ml of xylene into a three-necked flask equipped with a water separator, thermometer, condenser and stirring device, blow in nitrogen, and slowly heat to reflux at 140°C for 6.5h Finally, at 190-200mmHg, distill under reduced pressure for 2.5-3h, then at 20-25mmHg, distill under reduced pressure for 1-2h, until no liquid flows out, after cooling, add 110ml of 10% NaCl aqueous solution to the mixture and stir Evenly, heat the mixture to 80°C and keep it warm for 1h, cool and stand for 2.0h, separate the upper layer oil with a separatory funnel, wash with water twice, separate the water layer, and vacuum dry the oil phase to obtain a creamy oil-soluble fat-based N -Corrosion inhibitor of methyl benzimidazoline, weighing 48.3 g. Infrared spectrum (KBr): 1636, 1550, 1450cm -1 (Stretching vibration of benzene ring skeleton); 1575, 1455, 1410cm -1 (stretching vibration of imidazoline ring skeleton); 2868,...

Embodiment 3

[0034] In a three-necked flask equipped with a water separator, a thermometer, a condenser and a stirring device, add 30g of refined waste oil, 43.5g of N-phenyl-o-phenylenediamine and 80ml of xylene, feed nitrogen, and slowly heat to reflux at 140°C for 6.5 After h, distill under reduced pressure at 190-200 mmHg for 2.5-3 h, then distill under reduced pressure at 20-25 mmHg for 1-2 h until no liquid flows out. After cooling, add 120 ml of 10% NaCl aqueous solution to the mixture and Stir evenly, heat the mixture to 80°C and keep it warm for 1 hour, cool it and let it stand for 1.5 hours, separate the upper layer oil with a separatory funnel, wash it with water twice, separate the water layer, and dry the oil phase in vacuum to obtain the oil-soluble fat-based N- Phenylbenzimidazoline paste solid corrosion inhibitor, weighing 49.8g. Infrared spectrum (KBr): 1635, 1545, 1451cm -1 (stretch vibration of benzene ring skeleton); 1568, 1445, 1410cm -1 . 2875, 2891cm -1 (CH 3 ,C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com