Surface treatment process for aluminum base material conductor bus way

A surface treatment and busway technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve problems such as high cost, poor aluminum-aluminum contact conductivity, violation, etc., to improve surface conductivity, Solve the effect of anti-oxidation ability and reduce contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings will be used for a detailed description, as follows:

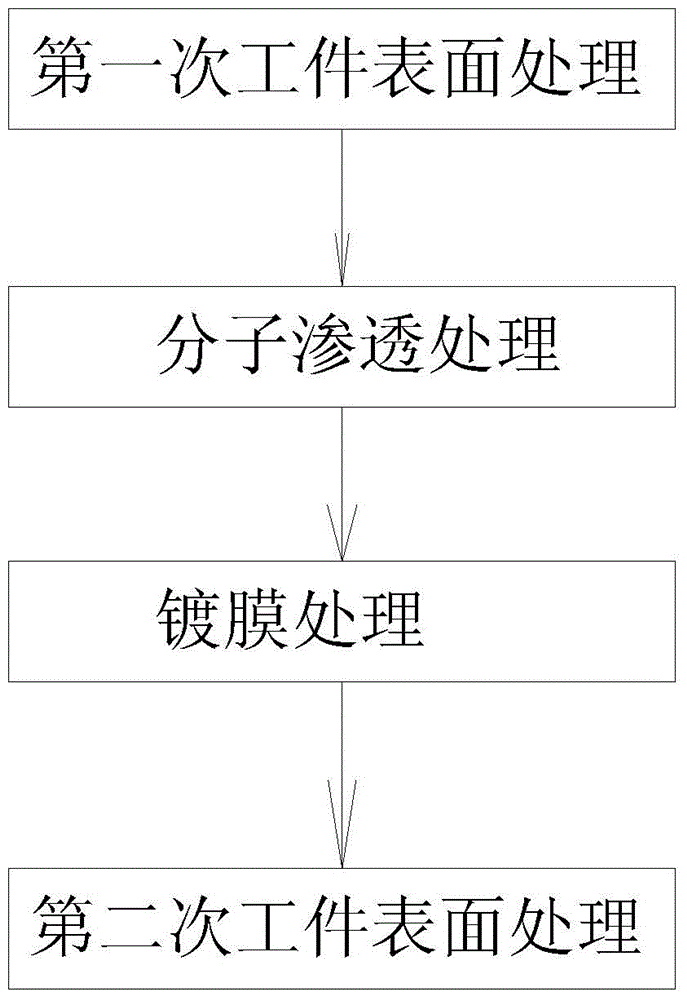

[0018] Such as figure 1 As shown, a surface treatment process of aluminum-based conductor busway, the process flow is the first workpiece surface treatment, molecular infiltration treatment, coating treatment, and the second workpiece surface treatment.

[0019] Among them, the first surface treatment includes degreasing, water washing, pickling and secondary water washing in sequence. The method of degreasing is alkaline chemical degreasing. The water washing after oiling and the water washing after pickling make the surface of the aluminum substrate busway smooth and clean.

[0020] Molecular osmosis treatment processes include:

[0021] a. Solution soaking: Soak in a mixed solution at 20-40°C for 20-40S. The mixed solution is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com