Plate plating hanger

An electroplating hanger and plate-type technology, which is applied in the electrolysis process and electrolytic components, etc., can solve the problems that the hanger deplating and pickling process is easily corroded, cannot be applied to small workpieces without hanging holes, and has a short service life. It is convenient and quick to put in or take out, save electroplating raw materials, and have high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following examples are further explanations and supplements to the present invention, and do not constitute any limitation to the present invention.

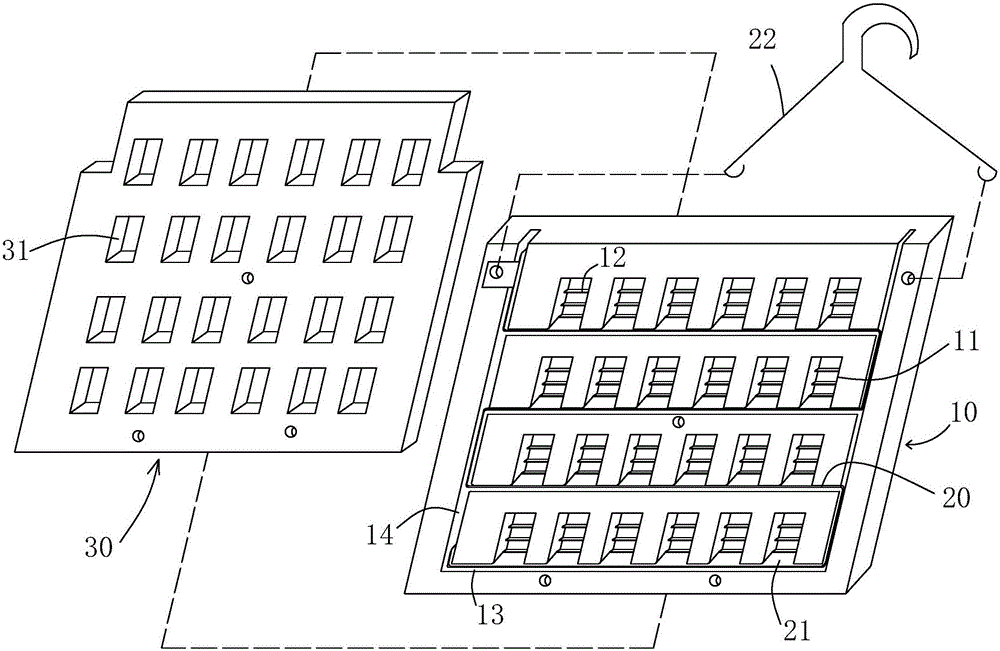

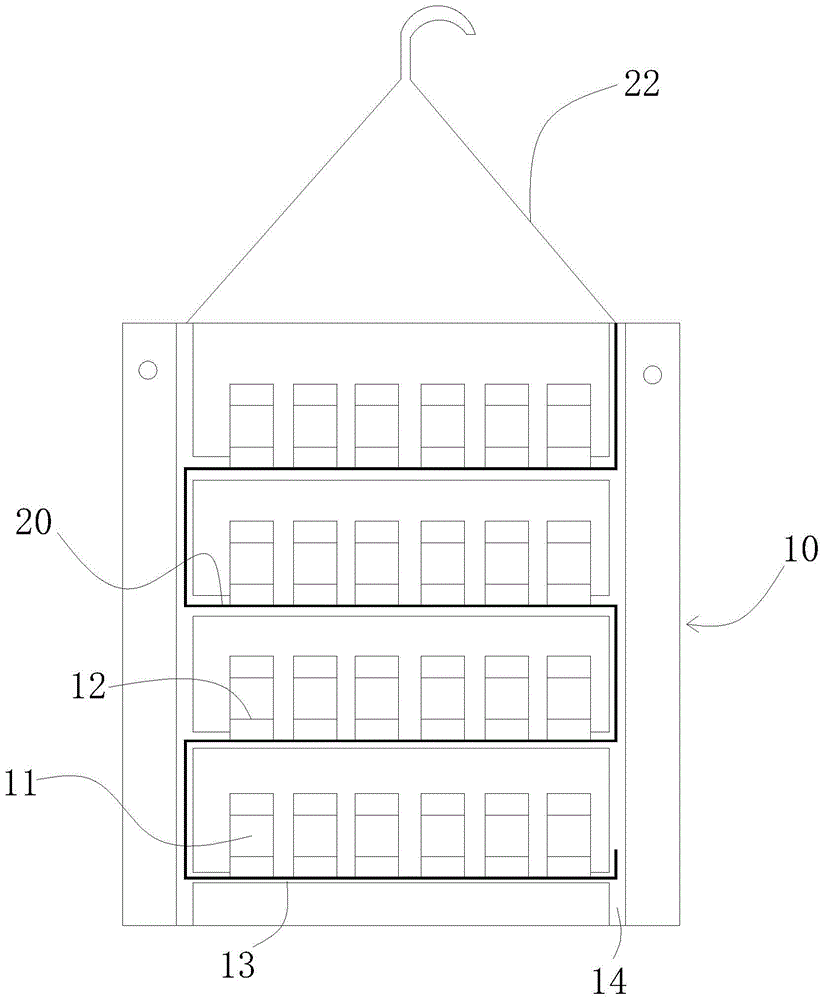

[0020] refer to figure 1 , The plate-type electroplating hanger of the present invention includes a plate-shaped base 10 , a metal cathode 20 and a cover plate 30 .

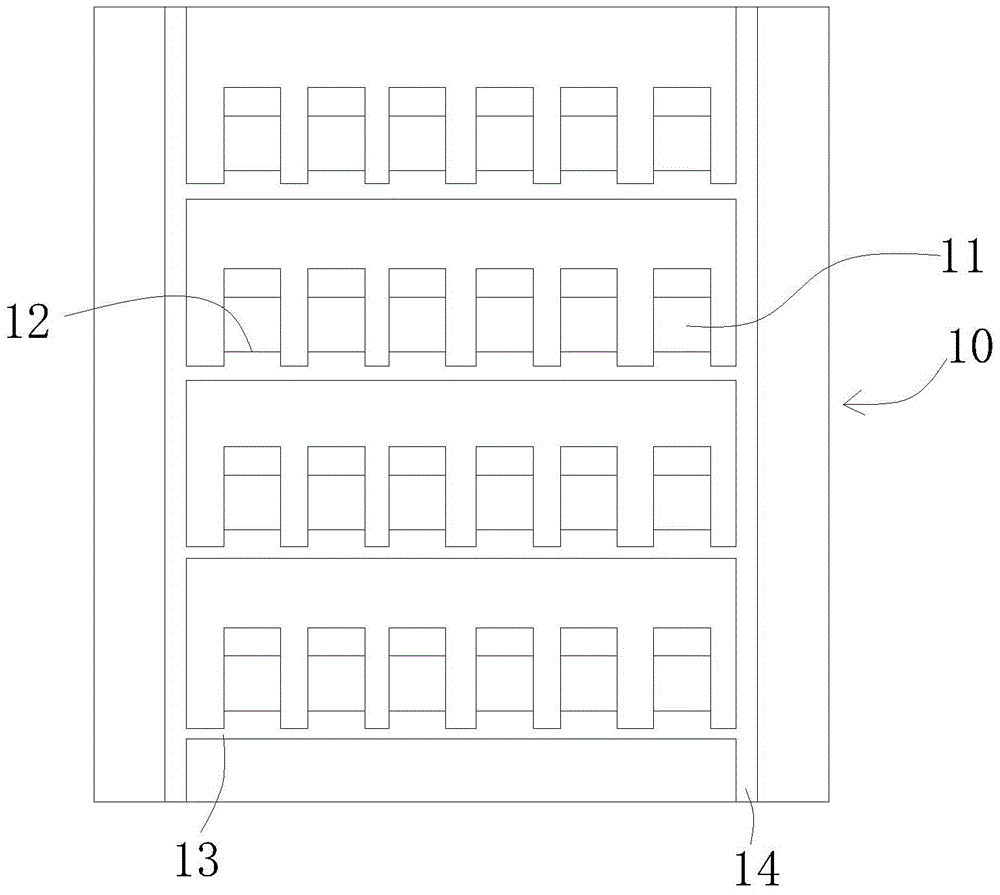

[0021] Such as figure 1 , figure 2 As shown, the plate base 10 is made of insulating material, and the plate base 10 may be made of polypropylene material, polyethylene material or other chemically stable insulating materials. In this embodiment, the plate base 10 is made of polypropylene material. Grid-like plating holes 11 are arranged on the plate base 10, and the plating holes 11 are arranged in multiple rows and columns at intervals. In this embodiment, the plating holes 11 are arranged in four rows and six columns at intervals. Each plated part hole 11 runs through from one side of the plate-shaped substrate 10 to the other side, and its cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com