Propellant/lining interface crack critical intensity stress factor detection method

A detection method and stress factor technology, applied in the direction of strength characteristics, measuring devices, instruments, etc., can solve the problems of uncertain evaluation indicators and complicated action process, and achieve the effects of reasonable indicators, convenient sample preparation, and reliable data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is further described by the embodiments provided by the accompanying drawings below.

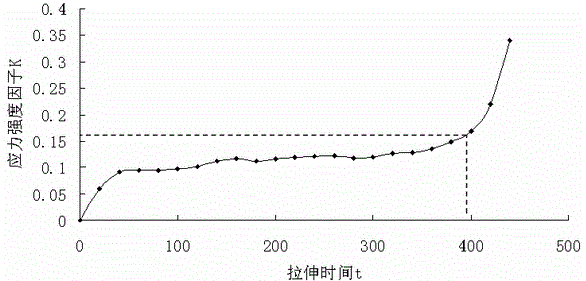

[0016] Taking the NEPE / HTPB / EDPM system as an example, NEPE is nitrate plasticized polyether, HTPB is hydroxyl-terminated polybutadiene, and EDPM is EPDM rubber. Propellant / liner interface crack stress intensity factor.

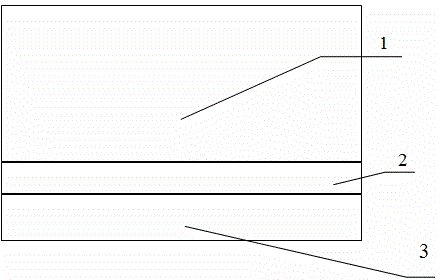

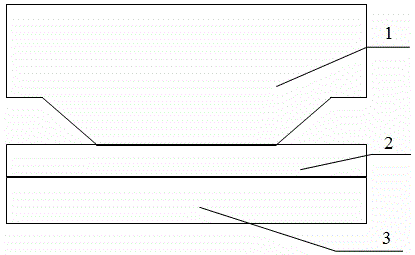

[0017] Step 1, sample preparation: sample selection and block making, test block slicing and cutting. When selecting samples and making blocks, select samples containing propellant / lining interface of different ages. The samples are cuboid test blocks containing propellant, liner, and thermal insulation layer. The specification is 10mm×10mm×20mm. The length direction is consistent with the horizontal direction of the propellant / liner interface. When slicing and cutting the test block, use a microtome to cut the test block into slices with a thickness of 1 mm, and cut the slices through a stamping die to obtain a propellant / lining interface sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com