Transformer winding material identification method based on resistance temperature coefficient

A technology of temperature coefficient of resistance, transformer winding, applied in the direction of material resistance, etc., can solve the problems of irreversibility, low accuracy, time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

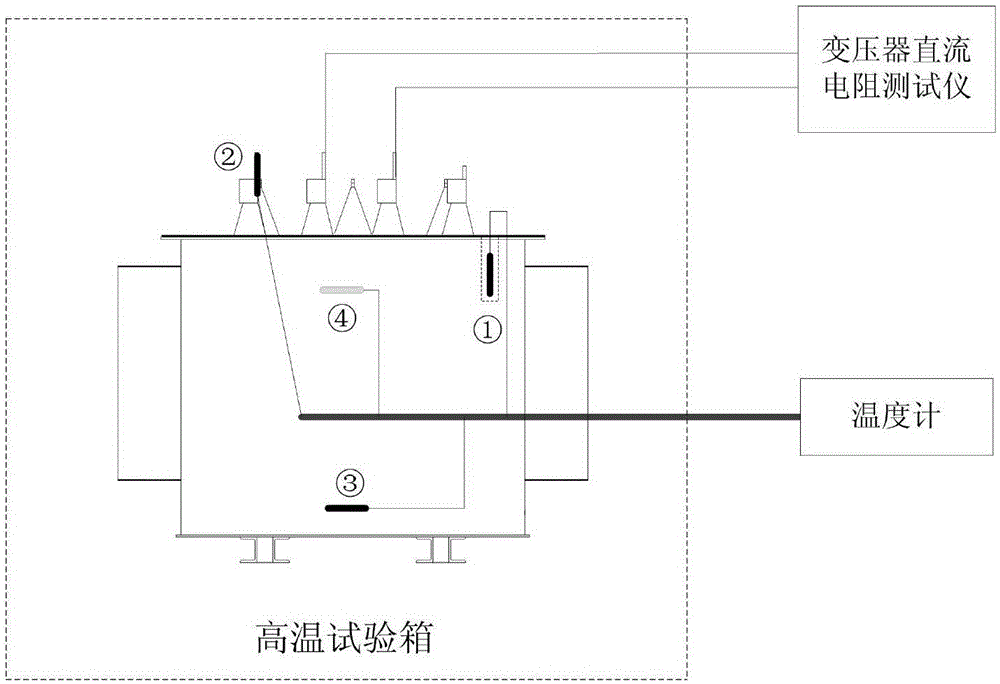

[0021] like figure 1 As shown, a transformer winding material identification method based on the temperature coefficient of resistance, the steps are:

[0022] 1) Place the transformer to be tested in a high-temperature test box (20-100°C), and arrange 4 temperature measurement points around it, namely: top oil temperature point, winding joint point, front bottom point, back top point, by measuring this The temperature of the transformer winding is judged by the temperature of the four points; change the temperature of the high temperature test box, and when the temperature of the transformer is completely stable, that is, the temperature of the four temperature measurement points is the same and is consistent with the set temperature of the test box, it is measured by the DC resistance tester of the transformer. DC resistance of the transformer winding;

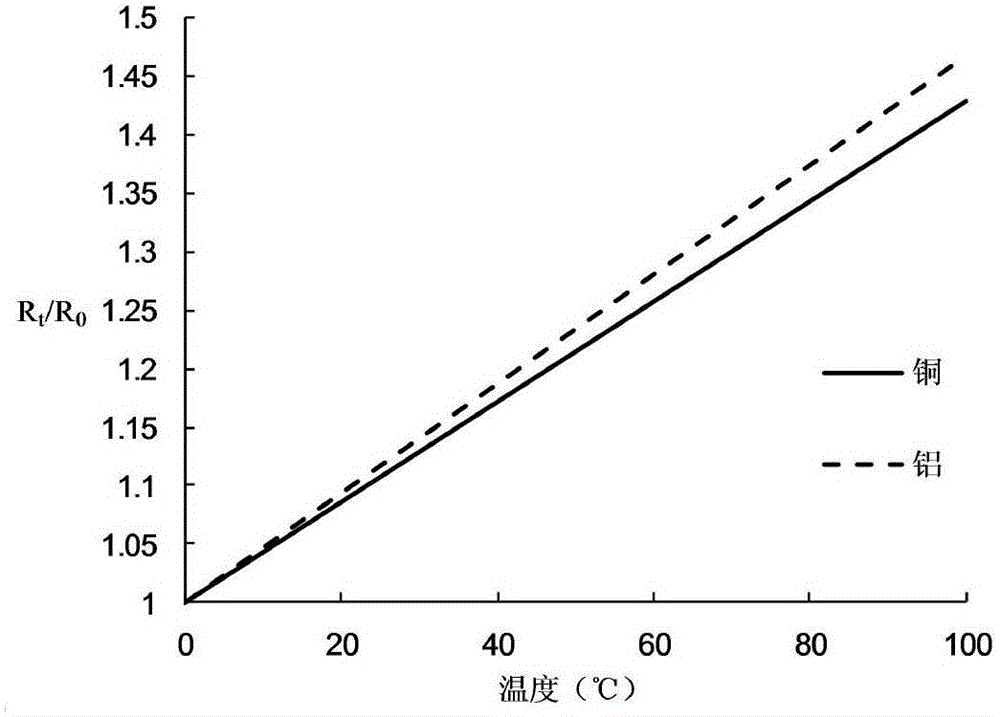

[0023] 2) Data analysis of the measured transformer winding DC resistance values at different temperatures:

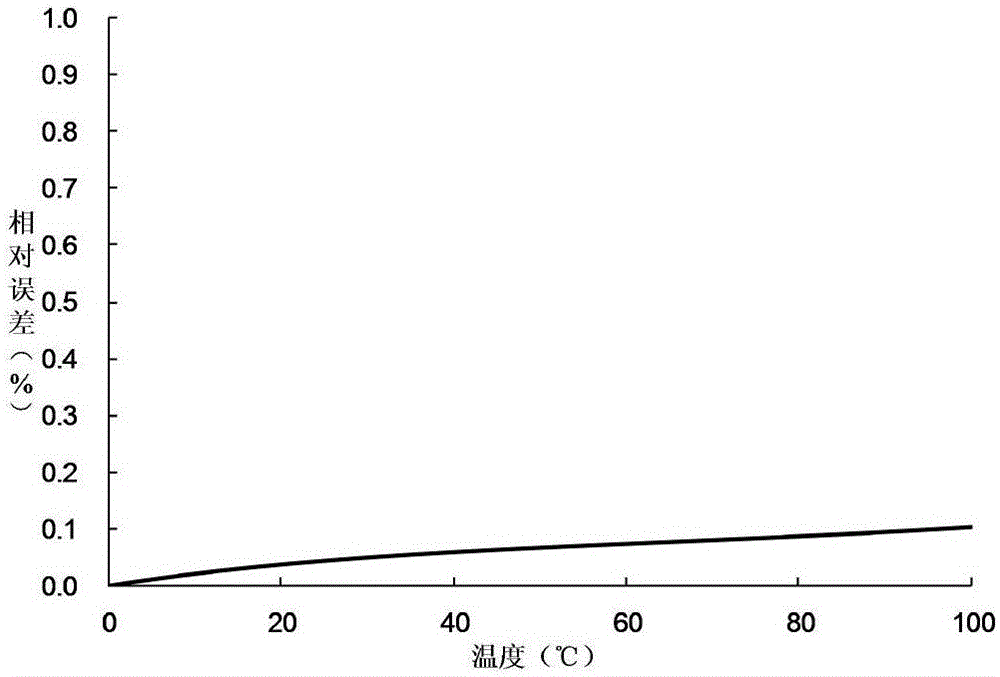

[0024] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com