Crank-slider-driven swing mirror mechanism

A crank slider and adjustment mechanism technology, applied in the direction of optical components, optics, instruments, etc., can solve the problem of high rotation accuracy and dynamic performance of torque motors, difficulty in overcoming the friction and influence of return springs, and affecting the adjustment of yaw angle Accuracy and other issues, to achieve the effect of low noise, simple structure, large adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

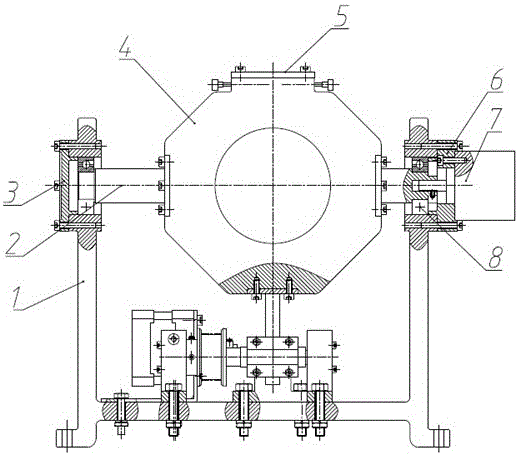

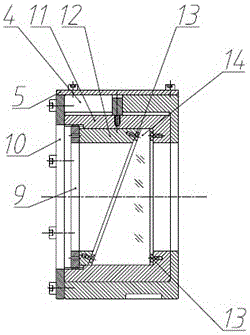

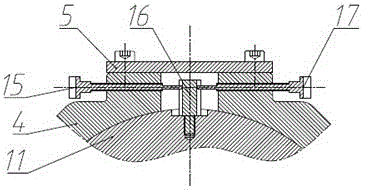

[0033] see Figure 1-Figure 6 as shown, figure 1 It is the overall structural diagram of the pendulum mirror mechanism driven by the slider crank of the present invention, figure 2 It is the structural diagram of the pendulum mirror and the picture frame assembly of the present invention, image 3 It is a structural diagram of the adjustment mechanism for the main section of the pendulum mirror of the present invention, Figure 4 It is a structural diagram of the motor and transmission mechanism of the present invention, Figure 5 It is a partial enlarged view of the crankshaft support structure of the motor and transmission mechanism of the present invention, Image 6 For the motor and the transmission mechanism of the present invention swing the slider part of the guide rod.

[0034] see figure 2First, put the small-diameter end of the nylon spacer 13 into the hole of the shaft shoulder of the inner lens frame 11 and the wedge-shaped pressure block 12, the pendulum mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com