Level shift circuit, level shift circuit driving method and pixel driving circuit

A technology of level shifting and driving power, applied in the direction of instruments, static indicators, etc., can solve the problems that the driving method is not simple and effective, the circuit structure is not simple enough, etc., and achieves a simple and effective driving method, simple structure and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

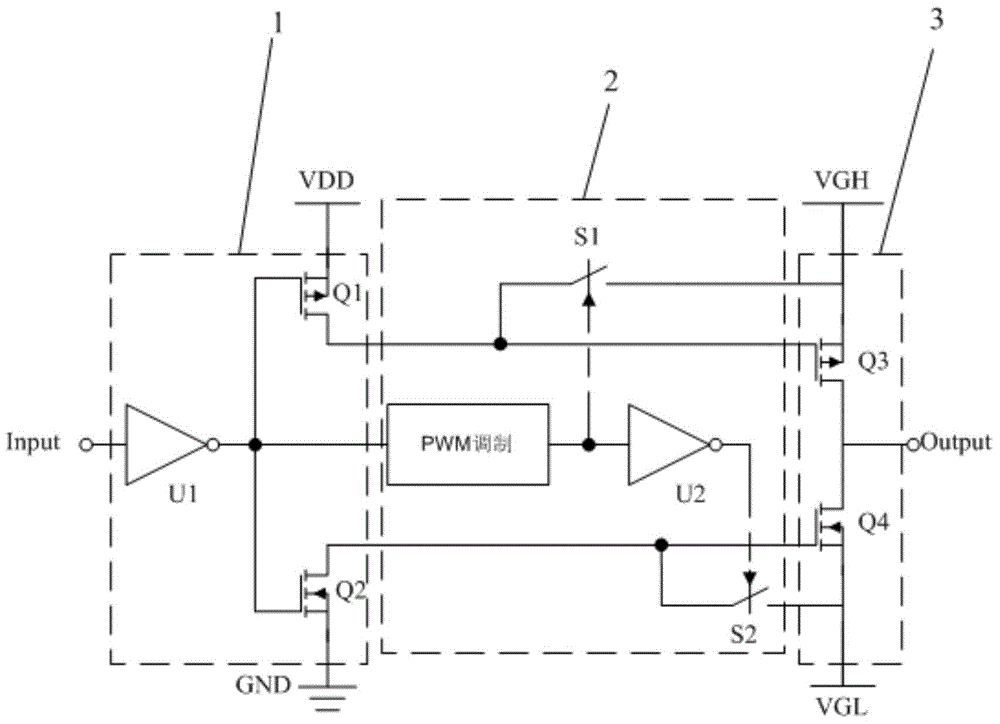

[0042] This embodiment provides a level shift circuit. The level shift circuit uses simple control logic to transform the input signal Input into the output signal Output, so as to realize the conversion of a small-amplitude level signal to a large-value level signal. conversion.

[0043] In this embodiment, a level shifting circuit applicable to a gate driver is taken as an example for illustration. like figure 1 As shown, the level shift circuit includes a control unit 1, a selection unit 2 and an output unit 3, wherein:

[0044] The control unit 1 is connected to the power supply, the input signal terminal and the selection unit 2, and is used to generate a control signal opposite to the input signal, and transmit the control signal to the selection unit 2; the positive level in the selection unit 2 can be controlled by the control unit 1 The switching on and off of the negative level path or the negative level path is convenient for the subsequent switching on and off of...

Embodiment 2

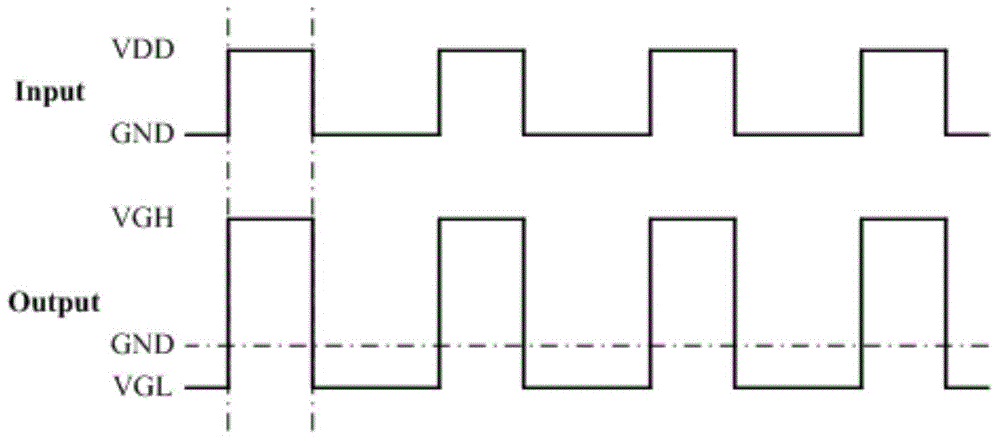

[0066] This embodiment provides a level shift circuit driving method corresponding to the level shift circuit in Embodiment 1, which can amplify the voltage and use the amplified voltage to drive pixels, wherein the level shift circuit includes a control Unit 1, selection unit 2 and output unit 3, the driving method includes a stage of outputting a positive voltage and a stage of outputting a negative voltage, wherein:

[0067] In the positive voltage output stage: the input signal and the positive logic voltage of turning on the power enter the control unit 1, and the control signal opposite to the input signal is generated in the control unit 1. Under the control of the control signal, the selection unit 2 selects the polarity corresponding to the turning on of the power. The high-level power supply of the driving power supply is output through the output unit 3;

[0068] In the negative voltage output stage: the input signal and the negative logic voltage of turning on the ...

Embodiment 3

[0078] Correspondingly, this embodiment provides a pixel driving circuit, which includes the level shift circuit of Embodiment 1 and adopts the driving method of the level shift circuit of Embodiment 2.

[0079] The pixel drive circuit has high reliability and can better realize display, and is especially suitable for being applied to a gate drive circuit in a liquid crystal display device LCD. Among them, the high-level signal VGH and the low-level signal VGL are the control levels acting on the gate drive terminal of the TFT-LCD pixel. When VGH is valid, the thin film transistor corresponding to the control pixel is turned on, and the new pixel data voltage Write pixel capacitance; when the VGL level is valid, control the thin film transistor corresponding to the pixel to turn off, so as to ensure that the pixel data voltage of this row is not modified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com