Power Signal Composite Cable

A power signal, composite cable technology, applied in the direction of insulated cables, communication cables, cables, etc., can solve the problems of fatigue damage of docking modules, reduced wiring reliability, unbalanced internal stress, etc., to improve reliability, uniform stress, The effect of reducing construction difficulty and construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

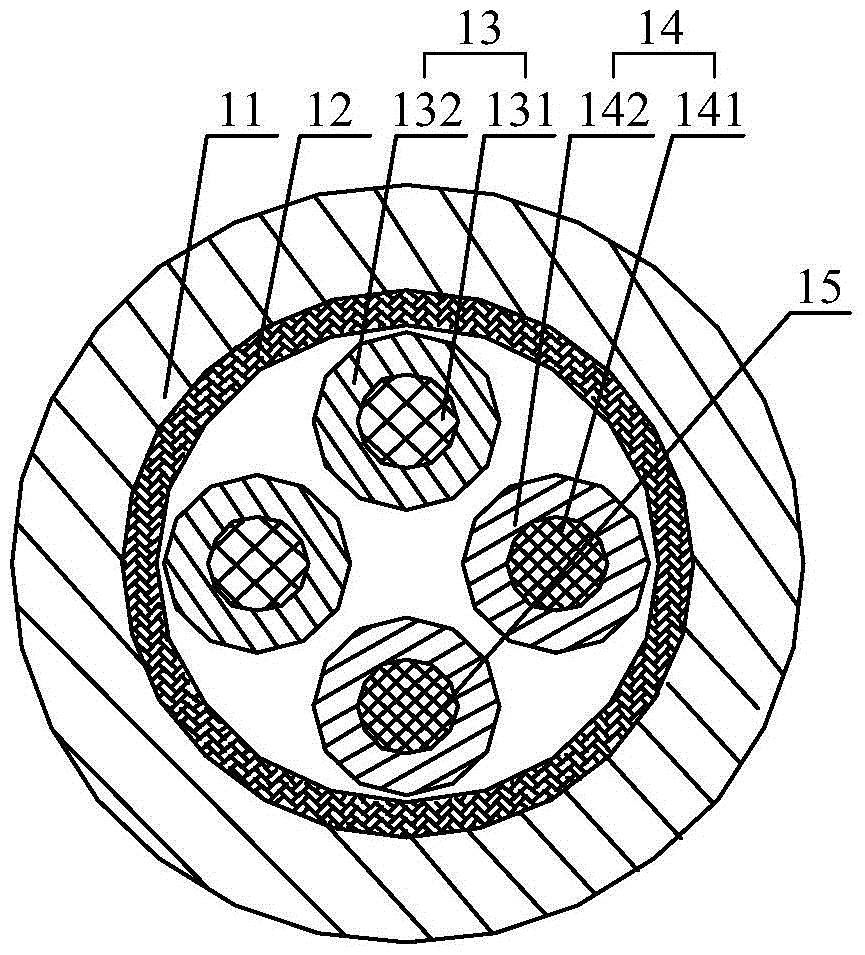

[0032] Please refer to the attached figure 1 , figure 1 The structure of the power signal composite cable provided by Embodiment 1 of the present invention is shown.

[0033] figure 1 The power signal composite cable shown includes a signal wire 13 , a live wire 14 , a ground wire 15 and a layer of outer sheath 11 sealed with plastic. Wherein, the plastic-molded outer sheath 11 covers the cable bundle formed by the signal wire 13 , the live wire 14 and the ground wire 15 .

[0034] The plastic-encapsulated outer sheath 11 is the peripheral protective part of the entire power signal composite cable. Usually, the plastic-molded outer sheath 11 can be made of PVC (Polyvinyl chloride, polyvinyl chloride), LSZH (Low Smoke Zero Halogen, low smoke zero halogen) material or PE (polyethylene, polyethylene) material. Of course, the plastic-molded outer sheath 11 can also be made of other materials, and this application does not limit the material of the plastic-molded outer sheath 1...

Embodiment 2

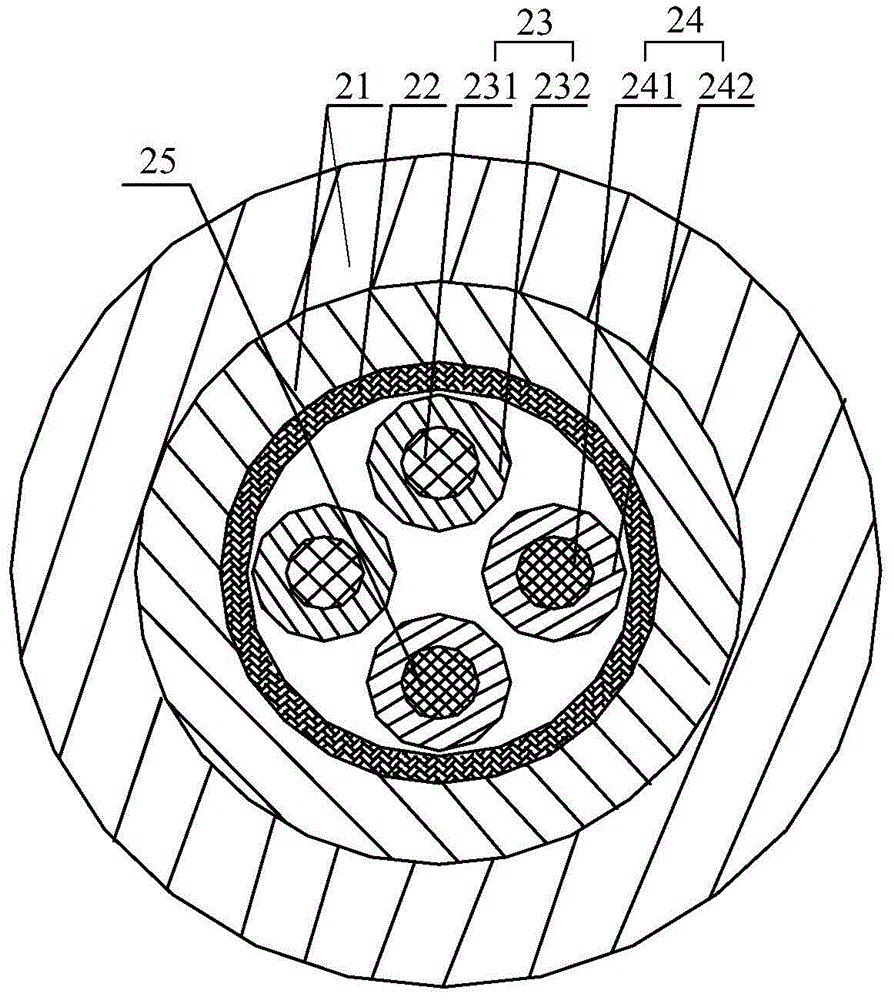

[0046] Please refer to the attached figure 2 , figure 2 The structure of the power signal composite cable provided by Embodiment 2 of the present invention is shown.

[0047] figure 2 The power signal composite cable shown includes a signal wire 23 , a live wire 24 , a ground wire 25 and at least two outer sheaths 21 sealed with plastic. Wherein, at least two layers of plastic outer sheaths 21 are covered on the cable bundle formed by the signal wire 23 , the live wire 24 and the ground wire 25 .

[0048] The plastic-encapsulated outer sheath 21 is the peripheral protective part of the entire power signal composite cable. Usually, the plastic-molded outer sheath 21 can be made of PVC material, LSZH material or PE material. Of course, the plastic-molded outer sheath 21 can also be made of other materials, and this application does not limit the material of the plastic-molded outer sheath 21 .

[0049] The structure of the live wire 24 and the ground wire 25 may be the s...

Embodiment 3

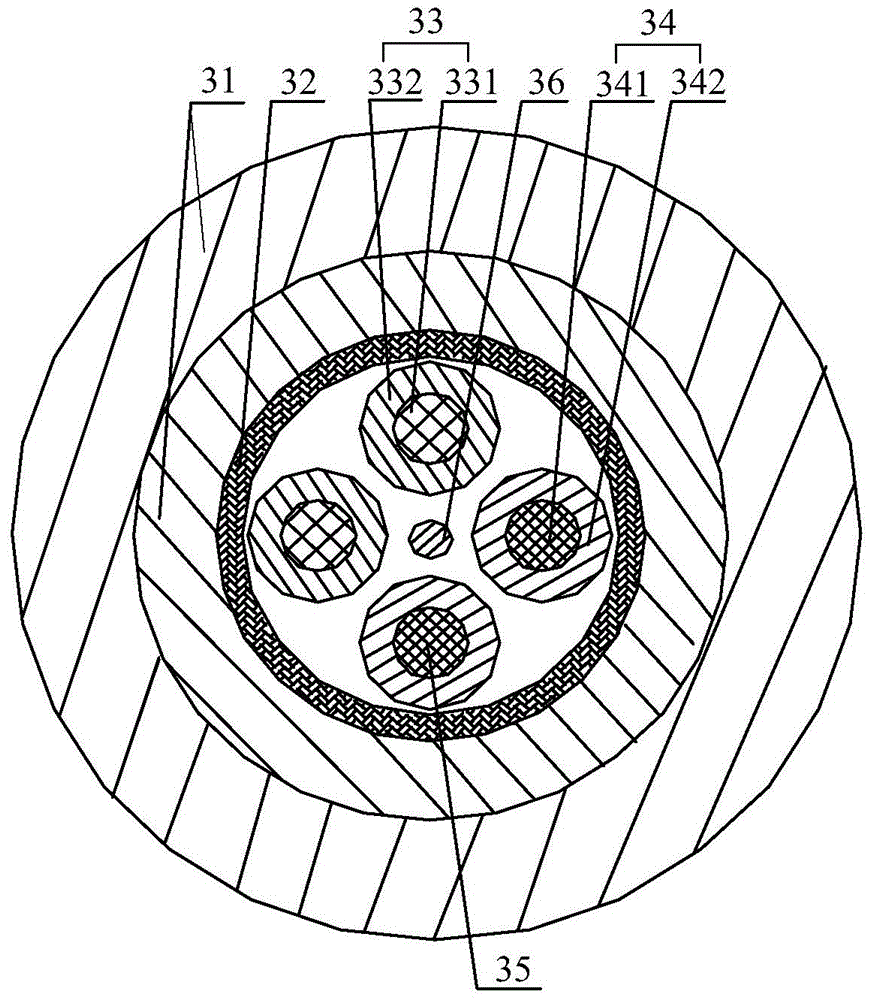

[0067] Please refer to the attached image 3 , image 3 The structure of the power signal composite cable provided by Embodiment 3 of the present invention is shown.

[0068] image 3 The power signal composite cable shown includes a signal wire 33 , a fire wire 34 , a ground wire 35 , a plastic-sealed outer sheath 31 and a reinforcing rib 36 . Wherein, the plastic-molded outer sheath 31 covers the cable bundle formed by the signal wire 33 , the live wire 34 and the ground wire 35 .

[0069] The plastic-encapsulated outer sheath 31 is the peripheral protective part of the entire power signal composite cable. Usually, the plastic-molded outer sheath 31 can be made of PVC material, LSZH material or PE material. Certainly, the plastic-molded outer sheath 31 can also be made of other materials, and this application does not limit the material of the plastic-molded outer sheath 31 .

[0070] The structure of the live wire 34 and the ground wire 35 may be the same, and both may...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com