Water transfer compound

A composite structure, water transmission technology, applied in the direction of final product manufacturing, electrochemical generators, chemical instruments and methods, etc., can solve the problems of complex positioning process, leakage, inaccuracy, etc., and achieve the effect of ensuring sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

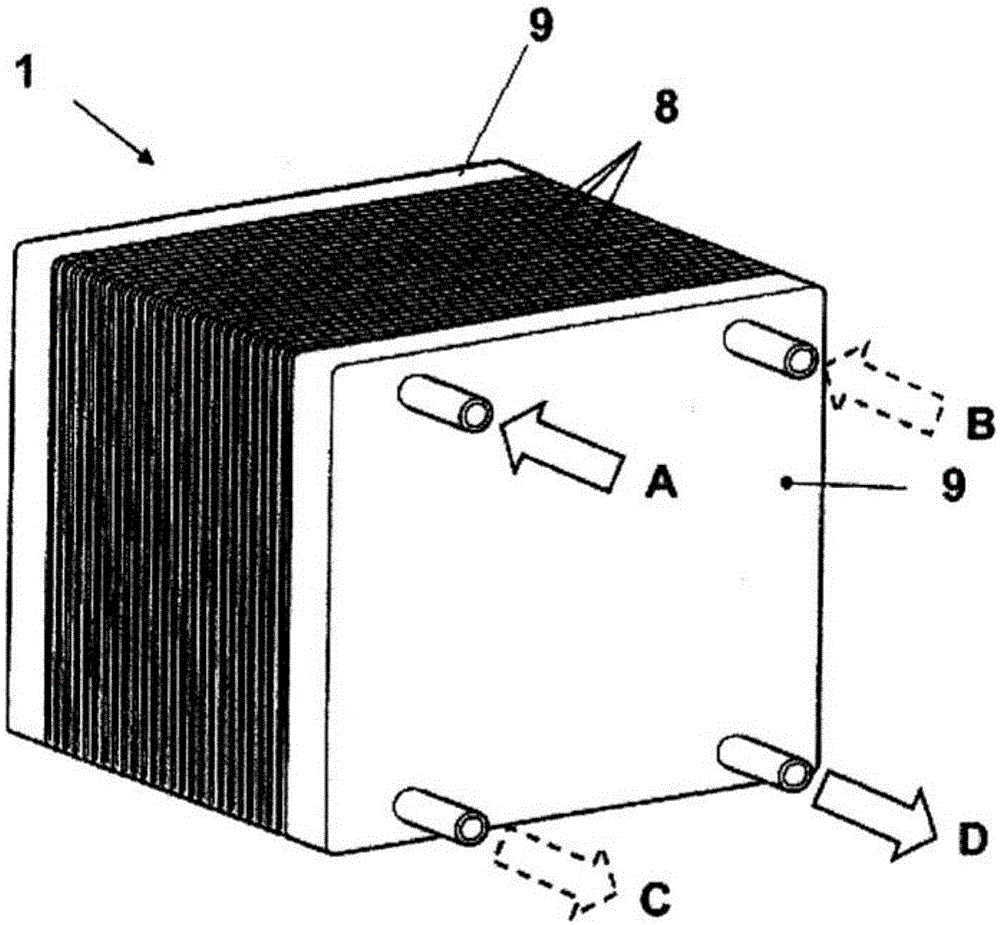

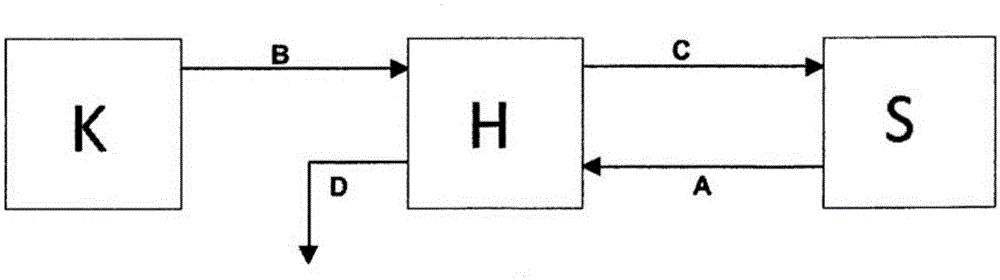

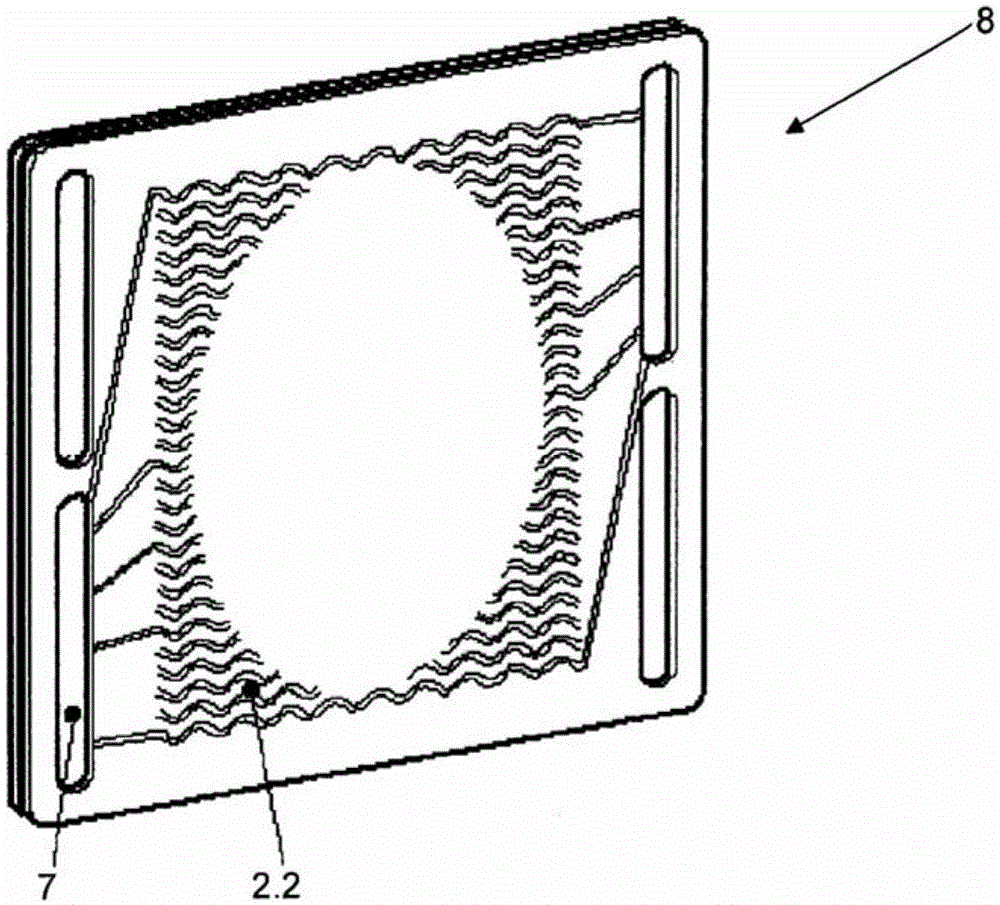

[0086] Figure 1a A humidifier 1 is shown comprising a plurality of layered humidifier modules 8 stacked and compressed between two end plates 9 . Gas is supplied and exhausted through the end plate. Thus, the humidifier 1 is a humidifier for the humidification of the process gas of the fuel cell, the humidifier 1 comprises a first inlet (arrow B) for supplying dry gas, a first outlet (arrow C) for discharging humidifier gas , a first inlet (arrow A) for supplying humidified gas, and a second outlet (arrow D) for discharging dehumidified gas. Figure 1b The whole configuration is shown schematically, where dry process gas is supplied from compressor K to humidifier H via supply line B, and humidified gas is supplied to fuel cell stack S via outlet C. The humid gas released from the fuel cell stack S is supplied via the supply line A to the humidifier H, where the humid gas releases the main part of the moisture of the humid gas to the dry gas supplied from the compressor K vi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com