A method of antioxidative enzymes combined with gas pretreatment of fresh meat

An antioxidant and pretreatment technology, applied in the preservation of meat/fish with chemicals, etc., can solve the problem that the antioxidant effect of antioxidant enzymes is not very good, reduce labor output, improve the degree of industrialization, and ensure meat products. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Cutting: The beef that has been cooled and deacidified and divided automatically enters the cold air conveyor belt through the cold air conveyor device, and the meat pieces are placed flat into the slicer for cutting, and the meat pieces with a thickness of 2cm are automatically output. The operating environment temperature is 8°C.

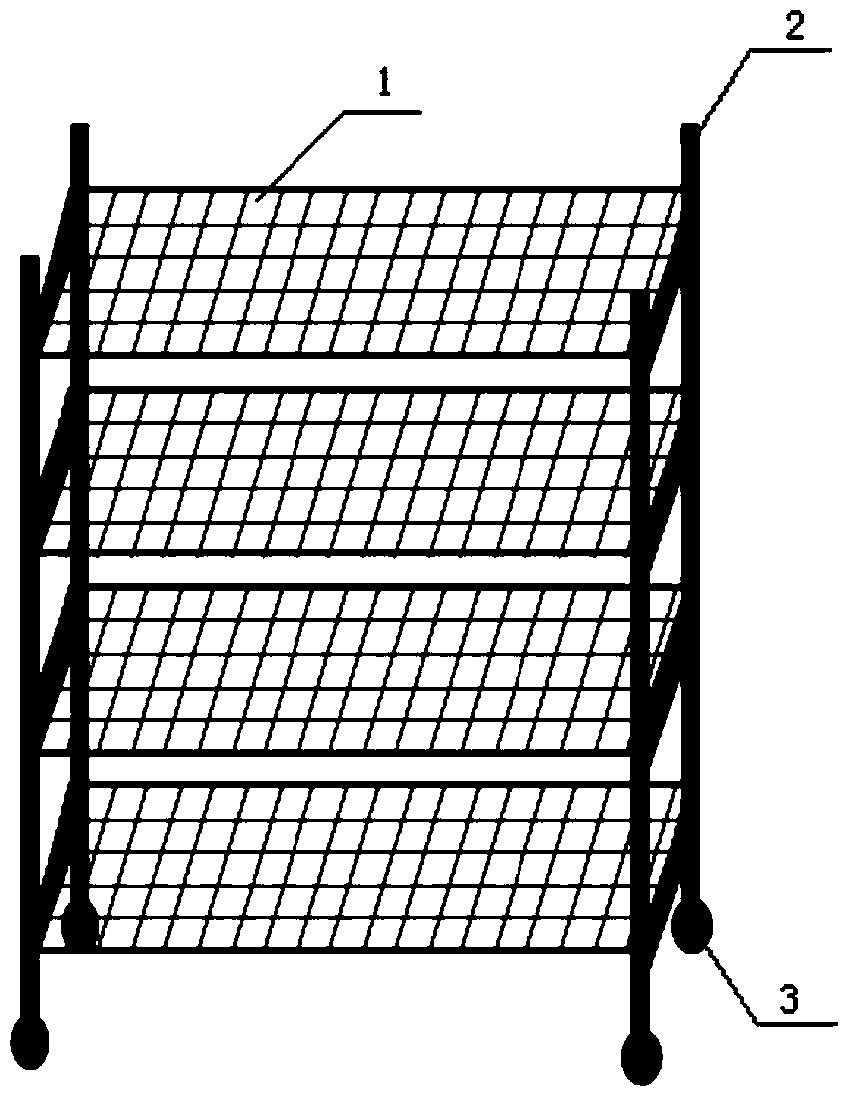

[0027] (2) Placement: Place the cut pieces of meat flat on the grid layer of the coloring rack, keep the distance between the meat pieces at 3cm, and do not overlap. Arrange between the coloring racks after the meat pieces are placed The gap is 6cm to ensure even hair color. Place the hair color rack on a large conveyor belt and send it into the gas chamber. The gas chamber turns on the exhaust fan to extract the indoor air. The pressure vacuum gauge is -0.3hPa. The frame body of the hair color stand is mainly formed by erecting four vertical poles with rollers at the bottom to form a three-dimensional space with a length, width and hei...

Embodiment 2

[0042] (1) Cutting: The beef that has been cooled and deacidified and divided automatically enters the cold air conveyor belt through the cold air conveyor device, and the meat pieces are placed flat into the slicer for cutting, and the meat pieces with a thickness of 2cm are automatically output. The operating environment temperature is 8°C.

[0043] (2) Placement: Place the cut pieces of meat flat on the grid layer of the coloring rack, keep the distance between the meat pieces at 3cm, and do not overlap. Arrange between the coloring racks after the meat pieces are placed The gap is 6cm to ensure even hair color. Place the hair color rack on a large conveyor belt and send it into the gas chamber. The gas chamber turns on the exhaust fan to extract the indoor air. The pressure vacuum gauge is -0.3hPa. The frame body of the hair color stand is mainly formed by erecting four vertical poles with rollers at the bottom to form a three-dimensional space with a length, width and hei...

Embodiment 3

[0058] (1) Cutting: The beef that has been cooled and deacidified and divided automatically enters the cold air conveyor belt through the cold air conveyor device, and the meat pieces are placed flat into the slicer for cutting, and the meat pieces with a thickness of 2cm are automatically output. The operating environment temperature is 8°C.

[0059] (2) Placement: Place the cut pieces of meat flat on the grid layer of the coloring rack, keep the distance between the meat pieces at 3cm, and do not overlap. Arrange between the coloring racks after the meat pieces are placed The gap is 6cm to ensure even hair color. Place the hair color rack on a large conveyor belt and send it into the gas chamber. The gas chamber turns on the exhaust fan to extract the indoor air. The pressure vacuum gauge is -0.3hPa. The frame body of the hair color stand is mainly formed by erecting four vertical poles with rollers at the bottom to form a three-dimensional space with a length, width and hei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com