Hydroxybutyl chitosan/oxidized sodium alginate/nano-silver composite hydrogel dressing plaster

A technology for oxidizing sodium alginate and hydroxybutyl chitosan, which is used in medical science, bandages, absorbent pads, etc., can solve the problems of mutual adhesion of wounds, unfavorable natural recovery of wounds, and unbearable pain for users, and achieves safety. Improve and prevent bacteria from invading wounds and have strong bactericidal and bacteriostatic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

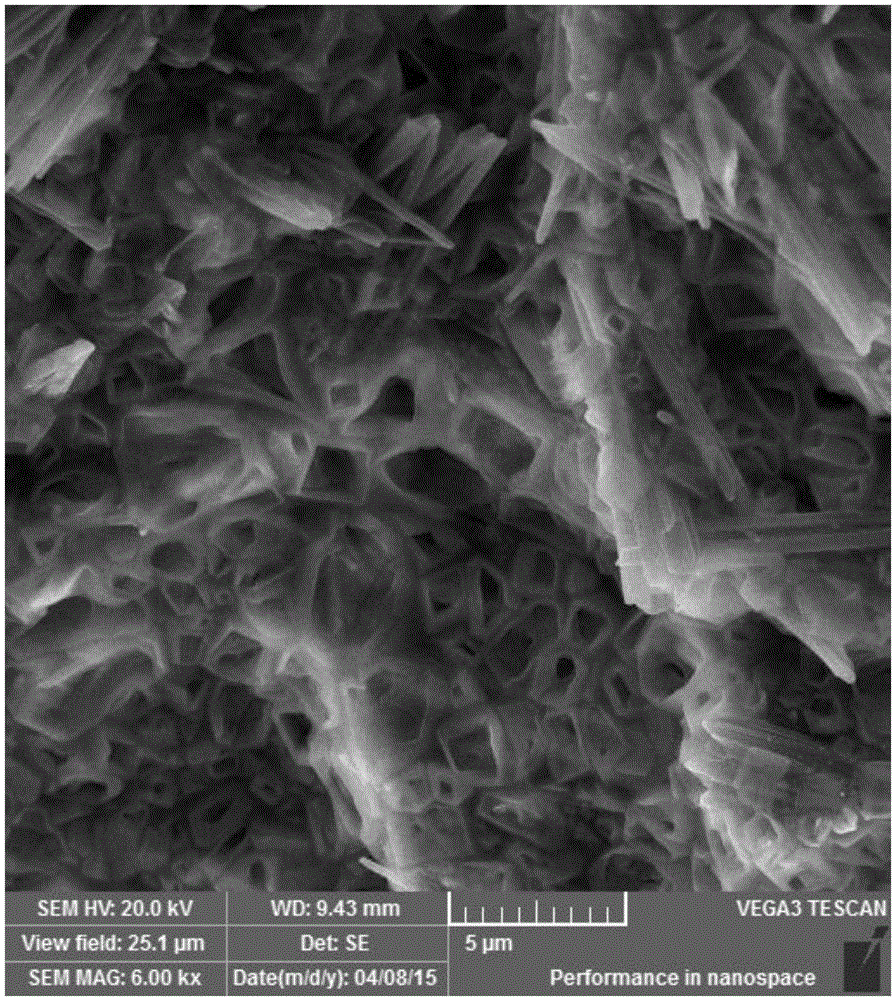

[0036] Embodiment 1: a kind of hydroxybutyl chitosan / oxidized sodium alginate / nano-silver composite hydrogel dressing, the steps of its preparation method are as follows:

[0037] 1. Set the specification to 60g / m 2 The medical non-woven fabric (3cm×3cm) is completely soaked in 10ml of 25wt% oxidized sodium alginate aqueous solution, loaded with cross-linking agent, soaked for 10min, then taken out and placed in a petri dish, and the unloaded oxidized sodium alginate aqueous solution was transferred to In the petri dish, all drop on the medical non-woven fabric;

[0038] 2. Add 2ml of 50μg / ml nano-silver colloid solution dropwise to 10ml of 16wt% hydroxybutyl chitosan aqueous solution and stir evenly to obtain mixed solution A;

[0039] 3. Evenly spread the mixed solution A on the medical non-woven fabric treated in step 1, and let it stand for 5-10 minutes. The cross-linking of the hydrogel is completed and combined with the medical non-woven fabric layer to form a whole. T...

Embodiment 2

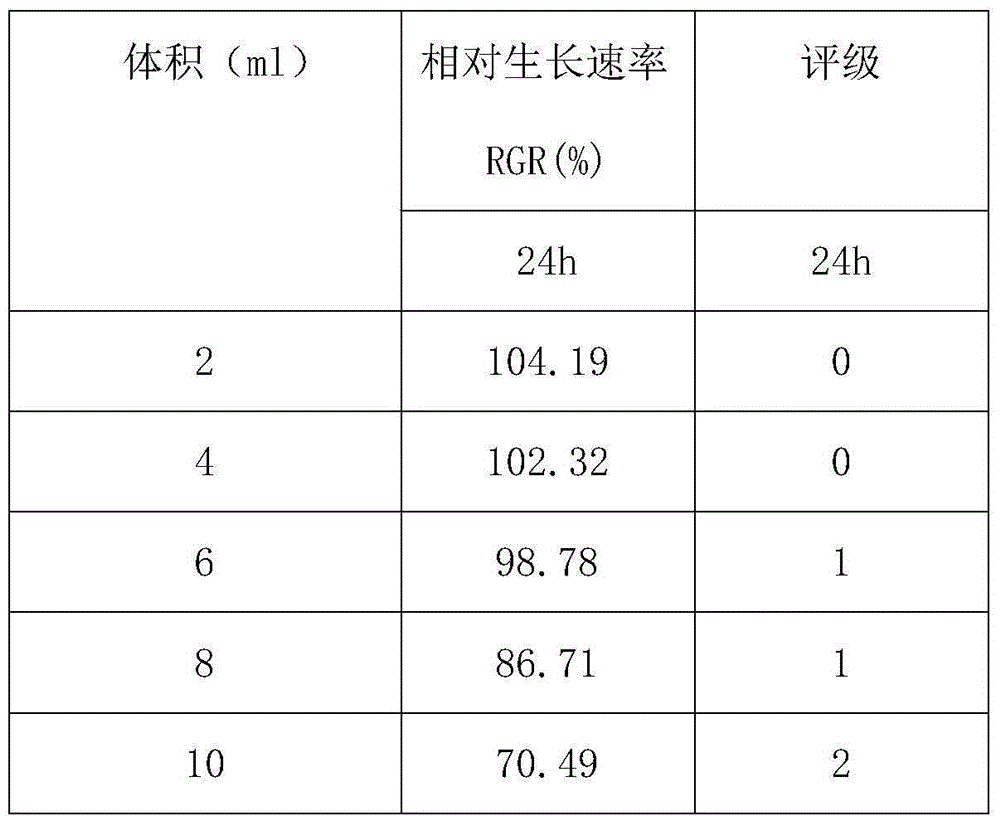

[0040] Embodiment 2: a kind of hydroxybutyl chitosan / oxidized sodium alginate / nano-silver composite hydrogel dressing, the steps of its preparation method are as follows:

[0041] 1. Set the specification to 60g / m 2 A medical non-woven fabric (3cm×3cm) was completely soaked in 10ml of 18wt% oxidized sodium alginate aqueous solution, loaded with a crosslinking agent, soaked for 10min, then taken out and placed in a petri dish, and the unloaded oxidized sodium alginate aqueous solution was transferred to In the petri dish, all drop on the medical non-woven fabric;

[0042] 2. In 10ml of 24wt% hydroxybutyl chitosan aqueous solution, drop 4ml of 50μg / ml nano-silver colloidal solution and stir evenly to obtain mixed solution A;

[0043] 3. Evenly spread the mixed solution A on the medical non-woven fabric treated in step 1, and let it stand for 5-10 minutes. The cross-linking of the hydrogel is completed and combined with the medical non-woven fabric layer to form a whole. This w...

Embodiment 3

[0044] Embodiment 3: a kind of hydroxybutyl chitosan / oxidized sodium alginate / nano-silver composite hydrogel dressing, the steps of its preparation method are as follows:

[0045] 1. Set the specification to 60g / m 2 The medical non-woven fabric (3cm×3cm) is completely soaked in 10ml of 25wt% oxidized sodium alginate aqueous solution, loaded with cross-linking agent, soaked for 10min, then taken out and placed in a petri dish, and the unloaded oxidized sodium alginate aqueous solution was transferred to In the petri dish, all drop on the medical non-woven fabric;

[0046] 2. Add 8ml 50μg / ml nano-silver colloid solution dropwise to 10ml 30wt% hydroxybutyl chitosan aqueous solution and stir evenly to obtain mixed solution A;

[0047] 3. Evenly spread the mixed solution A on the medical non-woven fabric treated in step 1, and let it stand for 5-10 minutes. The cross-linking of the hydrogel is completed and combined with the medical non-woven fabric layer to form a whole. This wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com