Full automatic mix push injection pump

A fully automatic, push-plate technology, applied in the field of medical devices, can solve problems such as the inability of continuous injection of drugs, personal injury to clinicians, and impact on treatment effects, avoiding incomplete and unstable emulsification, avoiding prolonged exposure to radiation, Avoid injecting too fast or too slow for effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

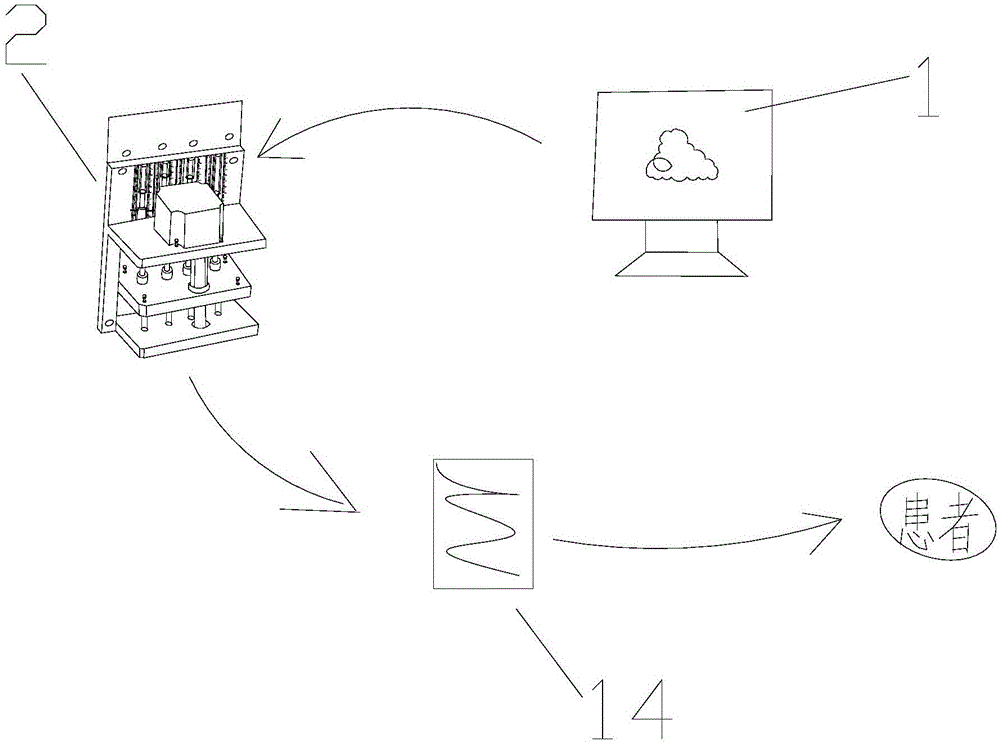

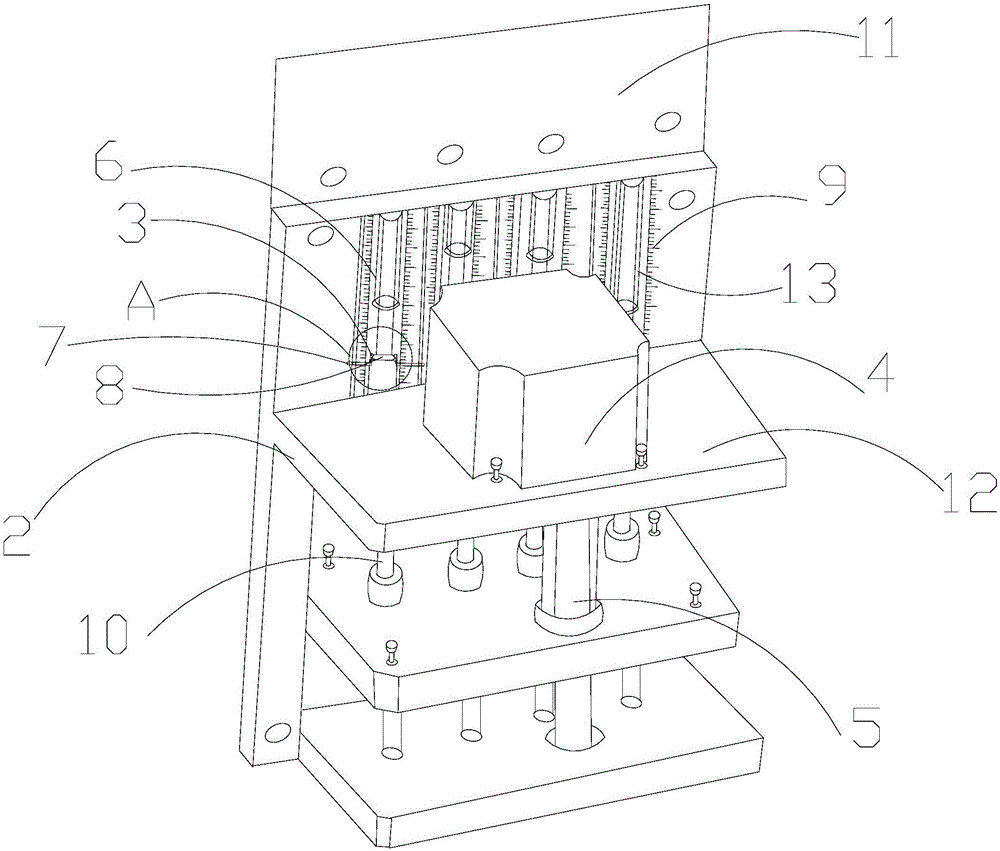

[0028] A kind of fully automatic mixing injection pump provided in this embodiment, such as Figure 1-6 As shown: it includes a main controller 1, a drug injection device 2 connected to the main controller 1, and an ultrasonic mixing emulsification device 14; the drug injection device 2 includes a bracket 11, a transmission device and four syringes 6, and the syringes 6 are fixed It is installed on the bracket 11, and a group of sliding grooves 13 are provided on the bracket 11, and the sliding adjustment block 7 is installed on the sliding grooves 13.

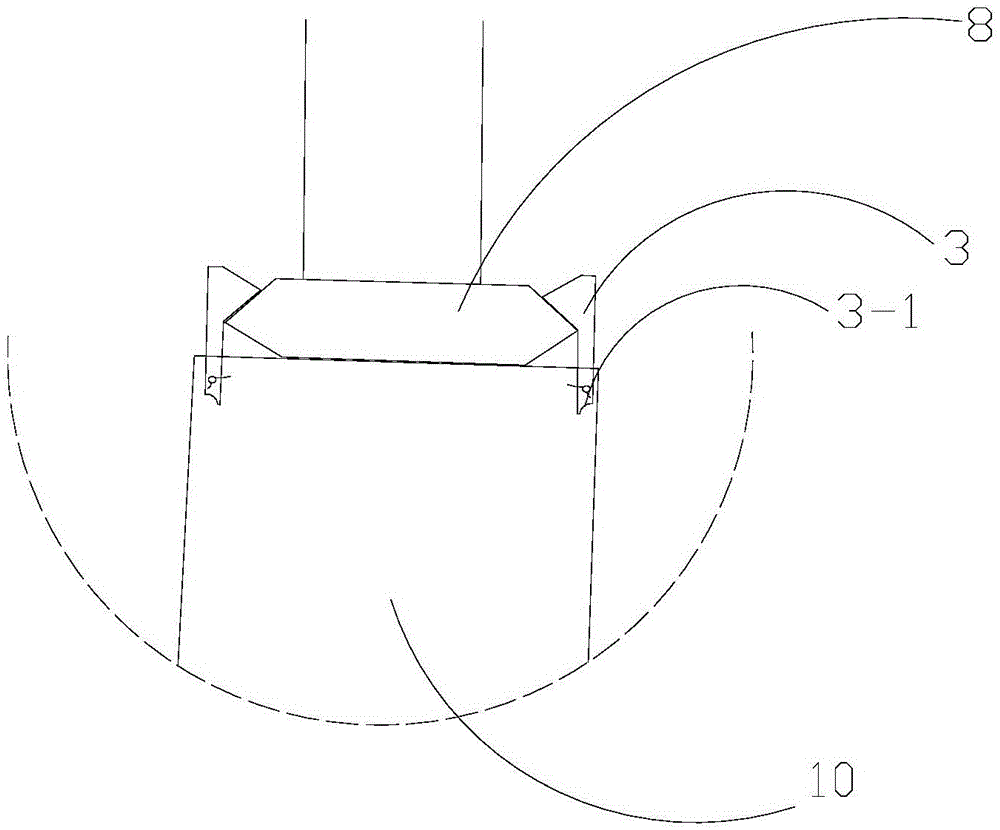

[0029] The transmission device includes a motor 4 fixedly installed on the bracket 11, a screw rod 5 and a push plate 12 connected with the motor 4 power; the push plate 12 is equipped with a guide post 10 corresponding to the position of the piston 8 of the syringe 6; the guide post 10 A buckle 3 is installed on both sides of the top of the torsion spring respectively; Hooks fitted with corner protrusions;

[0030] When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com