Organic modified activated carbon material and preparation method and application thereof

A modified and organic technology, applied in the field of organic modified activated carbon materials and its preparation, can solve problems such as not being able to meet production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

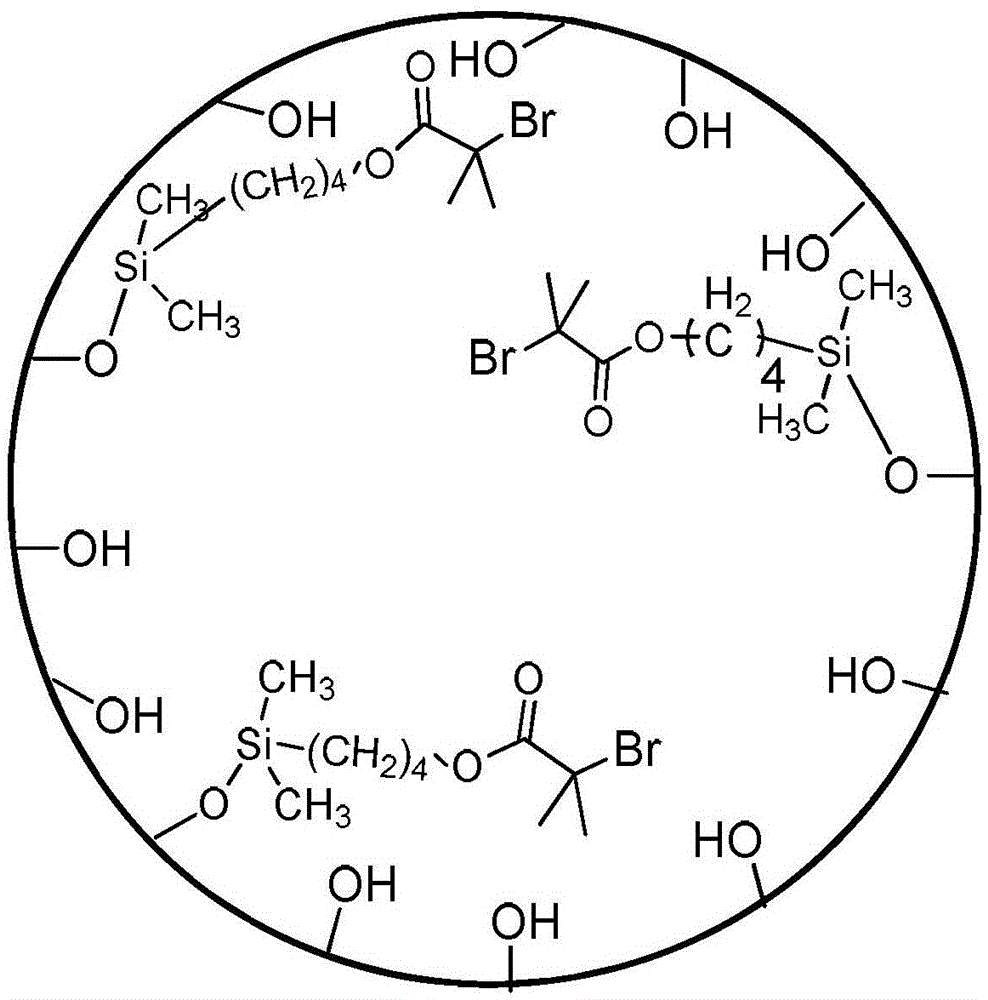

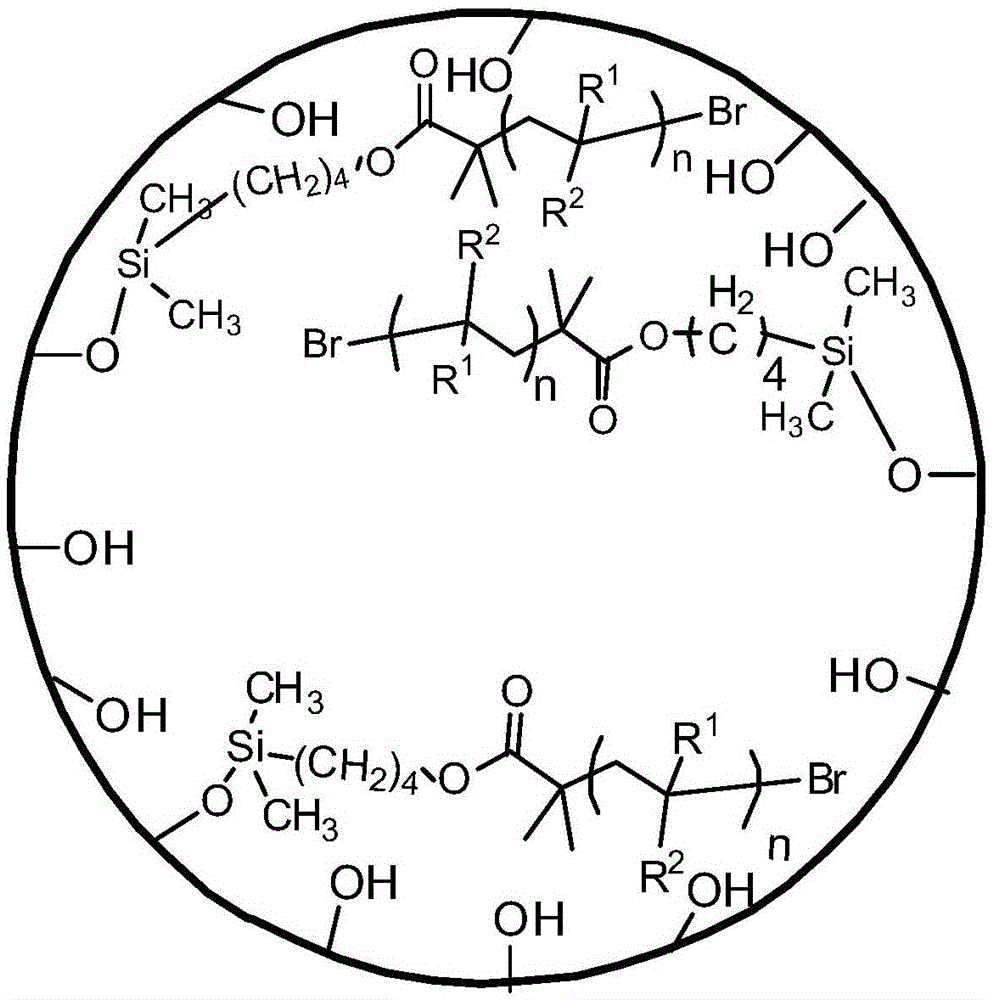

[0069] This embodiment provides an organically modified activated carbon and a preparation method thereof, which includes the following steps:

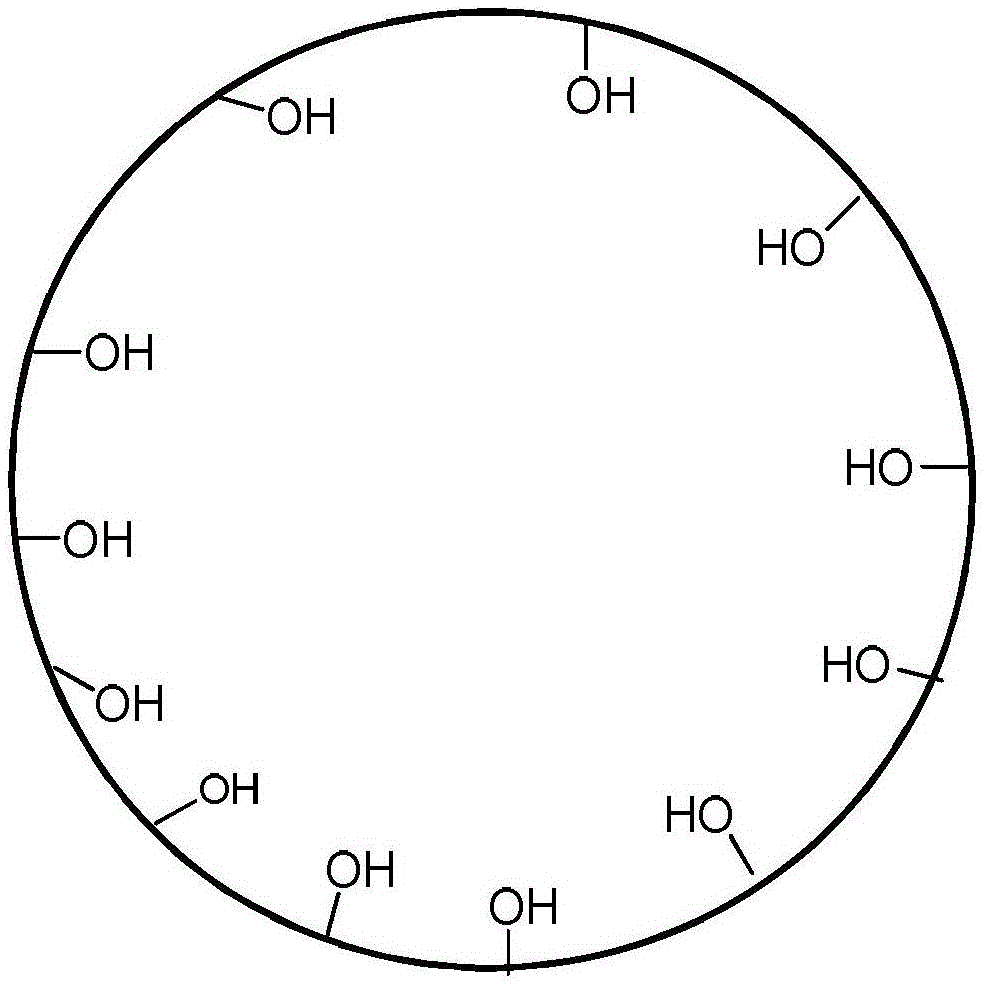

[0070] (1) Activation of activated carbon

[0071] 35mL of 2mol / L nitric acid solution was added to a Schlenk bottle containing 2g of activated carbon raw material, and the reaction was stirred at 60°C for 3 hours. After the reaction, it was cooled to room temperature, vacuum filtered, washed with deionized water for 3 to 5 times, and then dried at 110°C for 12 hours to obtain activated activated carbon. The structure diagram of activated carbon after activation is as Figure 1A As shown, its IR is figure 2 As shown in b, the IR of the activated carbon is about 3300cm -1 There are a lot of hydroxyl stretching vibration peaks, indicating that the obtained nitrated activated carbon has abundant hydroxyl groups. figure 2 In the IRa of the activated carbon before activation, it can be seen that the broad peak exhibited by the hydroxyl group ...

Embodiment 2

[0082] Example 2 Performance test of organically modified activated carbon material

[0083] Using the MicromeriticsASAP2020 physical adsorption instrument, the organic modified activated carbon material obtained in Example 1, the activated carbon of the grafting initiator, the activated activated carbon and the activated carbon raw materials were subjected to nitrogen adsorption and desorption tests under the same conditions. , Nitrogen adsorption and desorption isotherm such as image 3 Shown from image 3 It can be observed that the organic modified activated carbon material, the activated carbon of the grafting initiator and the activated activated carbon all have obvious hysteresis rings. The hysteresis ring of the activated carbon of the grafting initiator is less than that of the activated carbon. The organically modified activated carbon material is smaller than the grafted activated carbon of the initiator, indicating that the pores of activated carbon are gradually bec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com