Organic lead inhibitor and application thereof

An organic lead and inhibitor technology, applied in solid separation, flotation, etc., can solve problems such as environmental pollution, difficult wastewater treatment, poor operating environment, etc., and achieve the effect of solving poor operating environment and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Dissolve 71.0g of polyacrylamide with an average molecular weight of 20,000 in 200ml of water, add 22.8g of carbon disulfide, stir and mix thoroughly, and then add dropwise 40.0g of sodium hydroxide solution with a mass concentration of 30% to the above solution; the addition is complete Afterwards, the temperature was raised to 30° C., and the reaction was fully performed for 6 hours to obtain an orange-red organic lead inhibitor with a substitution degree of about 30% and a mass concentration of about 30%.

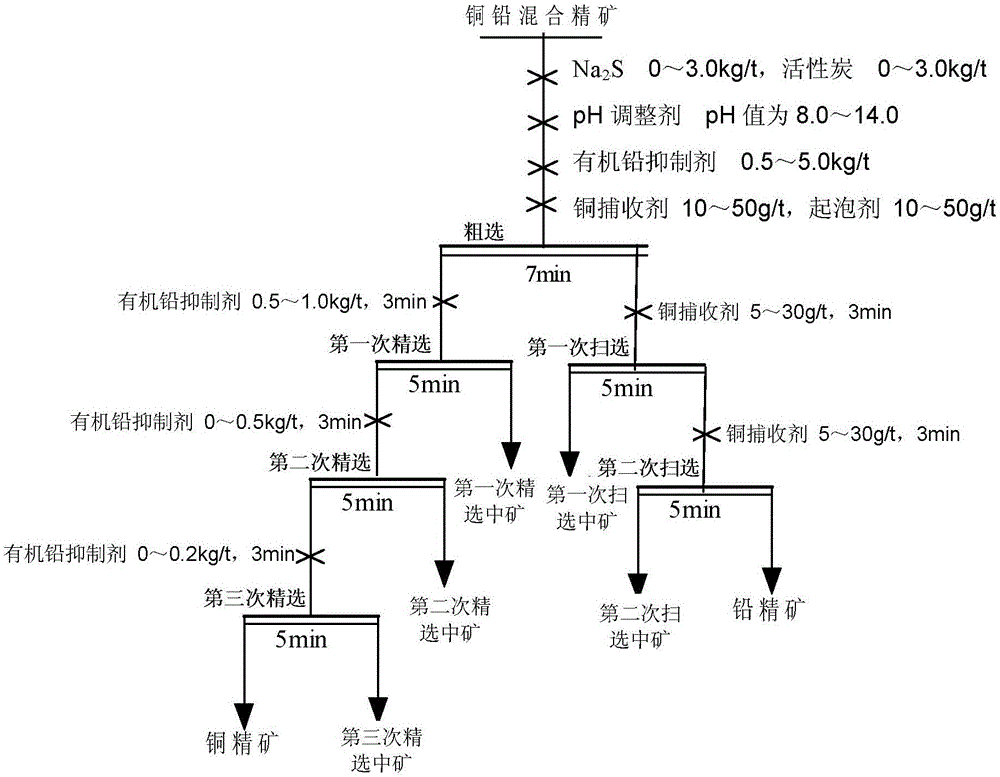

[0050] Utilize the organic lead inhibitor obtained in the above-mentioned embodiment 1 to carry out copper-lead separation test: the raw material is the copper-lead mixed concentrate obtained after the copper-lead mixed flotation operation of a certain copper-lead sulfide ore, the copper in the copper-lead mixed concentrate The grade of lead is 7.90%, and the grade of lead is 14.15%. After going through the "one rough, two sweeps and three fine" flotation processe...

Embodiment 2

[0053] Dissolve 71.0g of polyacrylamide with an average molecular weight of 100,000 in 200ml of water, add 38.0g of carbon disulfide, stir and mix thoroughly, then add 66.7g of sodium hydroxide solution with a mass concentration of 30% to the above solution dropwise; the addition is complete Afterwards, the temperature was raised to 30° C., and the reaction was fully performed for 8 hours to obtain an orange-red organic lead inhibitor with a substitution degree of about 50% and a mass concentration of 31.0-32.0%.

[0054] Utilize the organic lead inhibitor obtained in the above-mentioned embodiment 2 to carry out copper-lead separation test: raw material is the copper-lead mixed concentrate obtained after copper-lead mixed flotation operation of certain copper-lead sulfide ore, the copper in this copper-lead mixed concentrate The grade of lead is 7.90%, and the grade of lead is 14.15%. After going through the "one rough, two sweeps and three fine" flotation process described i...

Embodiment 3

[0057] Dissolve 71.2g of acrylamide-acrylic acid copolymer (in this acrylamide-acrylic acid copolymer, the molar ratio of acrylamide to acrylic acid is 8:2, the molecular weight is about 200000) in 200ml of water, and add 18.24g of carbon disulfide, stir well Mix, and then dropwise add 58.7g of sodium hydroxide solution with a mass concentration of 30% to the above solution; after the dropwise addition, the temperature is raised to 40°C, and the reaction is sufficient for 6 hours to obtain a degree of substitution of about 24%, and a mass concentration of 28.0 to 29.0 % of orange-red organic lead inhibitors.

[0058] Utilize the organic lead inhibitor obtained in the above-mentioned embodiment 3 to carry out copper-lead separation test: raw material is the copper-lead mixed concentrate obtained after copper-lead mixed flotation operation of certain copper-lead sulfide ore, the copper in this copper-lead mixed concentrate The grade of lead is 19.60%, and the grade of lead is 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com