Stacking method used in solid wood board drying

A board and drying technology, which is applied in the stacking, transportation and packaging of objects, can solve the problems of reduced wood utilization rate, increased number of shavings, and reduced volume, so as to achieve compressed processing allowance, reduced planing amount, The effect of improving the material yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

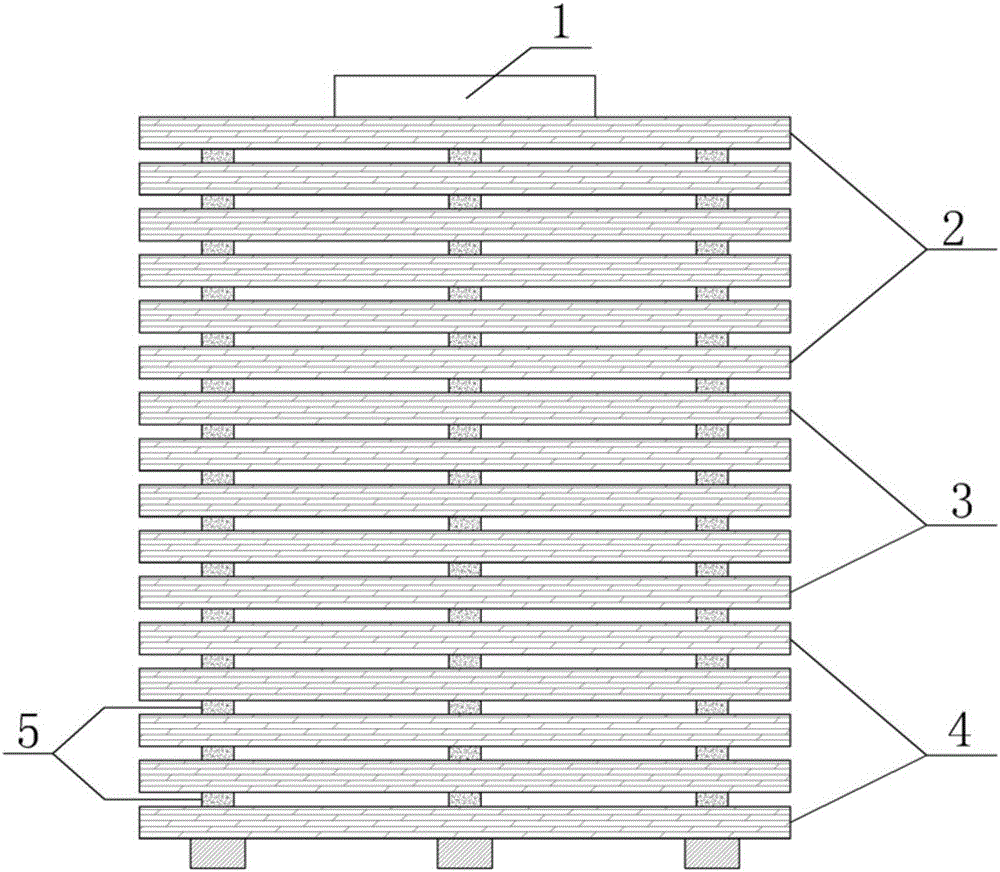

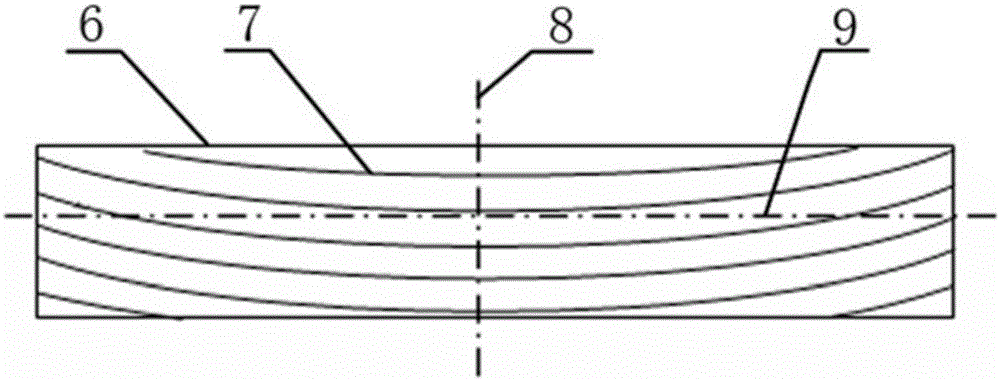

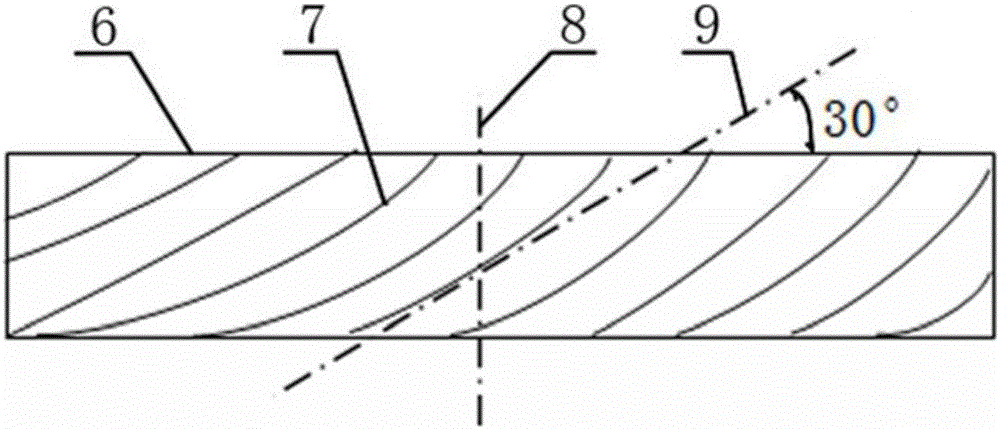

[0014] A stacking method for solid wood boards when they are dry. After the logs are processed and sawn into boards, they still contain a lot of water inside. In order to meet the needs of transportation and further processing, most of the water must escape from the wood to reduce its moisture content to The scope of technical requirements, this process is called wood drying, the drying treatment of solid wood panels, whether it is natural drying or artificial drying, before drying, the panels need to be stacked into stacks according to certain technical requirements, stacking methods and process requirements It will have a decisive impact on the drying quality and drying duration; the method of the present invention is to saw the log into boards of various thicknesses, including rough-edged boards and trimmed boards, and the described trimmed boards are: two opposite sides of solid wood boards The two wide surfaces are parallel to each other, and the adjacent material surfaces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com