A hybrid prestressed concrete-filled steel tubular pile

A technology for concrete-filled steel tubular piles and concrete piles, which is applied to sheet pile walls, construction, infrastructure engineering, etc., can solve problems such as non-compliance with product quality standards, low qualification rate, cracks, etc., to avoid product defects and improve the qualification rate. , the effect of reducing the contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

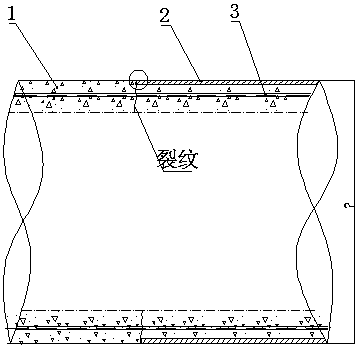

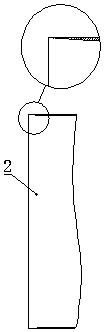

[0028] Such as figure 2 As shown, it includes a concrete pile body 1, a reinforcement cage 3 built into the concrete pile body 1, and a steel pipe 2 coated outside a part of the concrete pile body 1. The steel pipe 2 is covered at the end of the concrete pile body 1, and the steel pipe 2 The outer diameter of the concrete pile body 1 is the same as that of the concrete pile body 1, and the reinforcement cage 3 is composed of a number of prestressed steel bars extending axially along the concrete pile body 1 and distributed in a ring, and spiral stirrups welded outside the prestressed steel bars.

[0029] The end faces of the two ends of the concrete pile body 1 are provided with end plates 5 connected with the prestressed steel bars of the reinforcement cage 3, and the skirt board 4 is arranged at the end of the concrete pile body 1 without the steel pipe 2, and the skirt board 4 is connected with the side end. The plate is welded and fixed.

[0030] In this embodiment, its ...

Embodiment 2

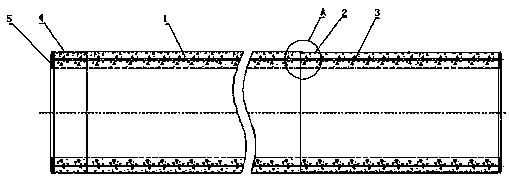

[0036] Such as Figure 5~7 As shown, it includes a concrete pile body 1, a reinforcement cage 3 built in the concrete pile body 1, an end plate 5 is provided on the end surface of the concrete pile body 1, and the two end plates 5 are respectively connected with the prestressed tendons at both ends of the reinforcement cage 3.

[0037] One end of the concrete pile body 1 is provided with a steel pipe 2 covering the outside of the pile body, the outer end of the steel pipe 2 is welded and fixed to one of the end plates, and the other end of the concrete pile body 1 is provided with an apron 4, the apron 4 Welded with the other end plate.

[0038] In this embodiment, the concrete pile body 1 on the axially inner side of the steel pipe 2 is covered with a transition pipe 6, and the nozzle at the axially outer end of the transition pipe 6 and the inner end of the steel pipe 2 are both provided with outer grooves for welding, so that The nozzle at the axially outer end of the tran...

Embodiment 3

[0042] Such as Figure 8 As shown, the concrete pile body 1 is included, and the concrete pile body 1 has a built-in steel cage 3, and a section of steel pipe 2 is covered on the outer surface of the middle part of the concrete pile body 1, and the two ends of the concrete pile body 1 are provided with steel cage 3 The end plate 5 connected to the end of the prestressing tendon is welded with the skirt plate 4 covering the end of the concrete pile body 1 .

[0043] Both ends of the steel pipe 2 are provided with transition pipes 6 covering the outside of the concrete pile body 1 , and one end of each transition pipe 6 is welded and fixed to the steel pipe 2 .

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com