Testing device and testing method for dynamic characteristic of joint curved surface faying surface

A technology for dynamic characteristics and testing devices, which is applied in measurement devices, vibration testing, and testing of machine/structural components, etc., can solve the problems of inability to test the dynamic characteristics of the joint surface of the joint surface, no interchangeability, and high cost of the test bench. To achieve the effect of simple and easy measurement method, improve the reuse rate and good economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

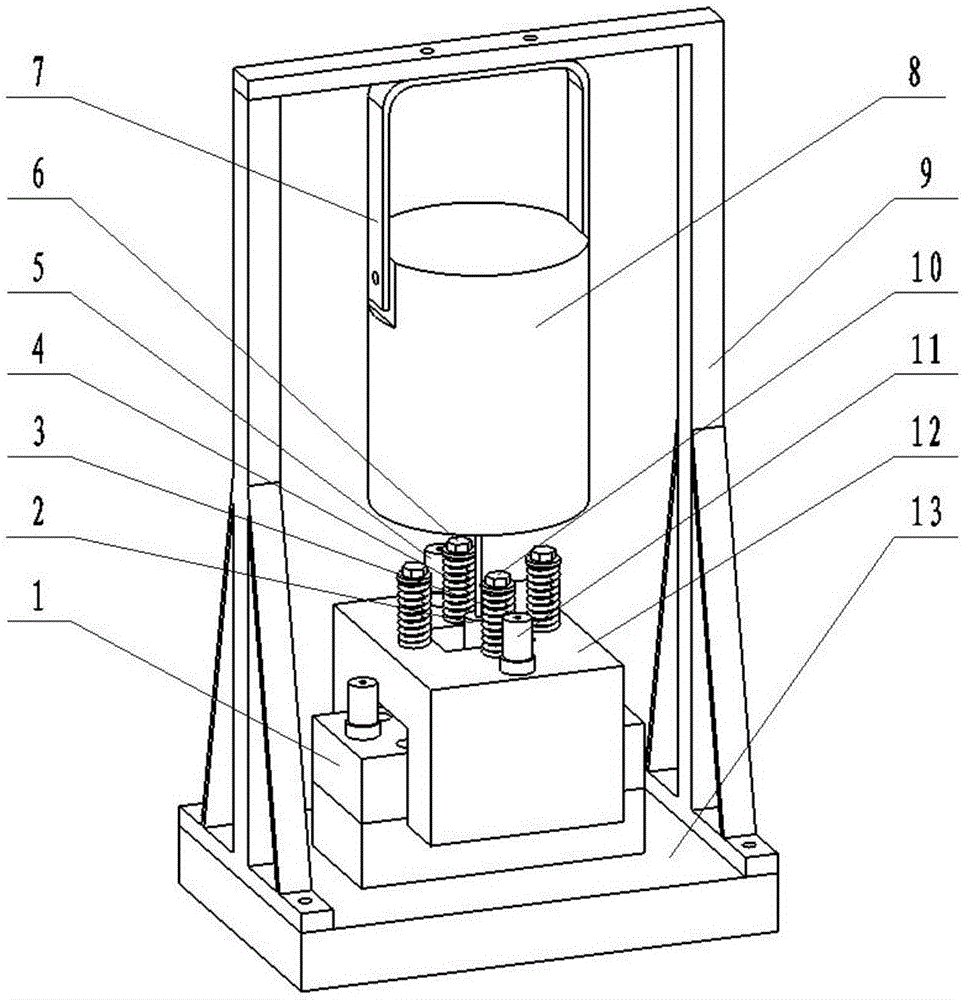

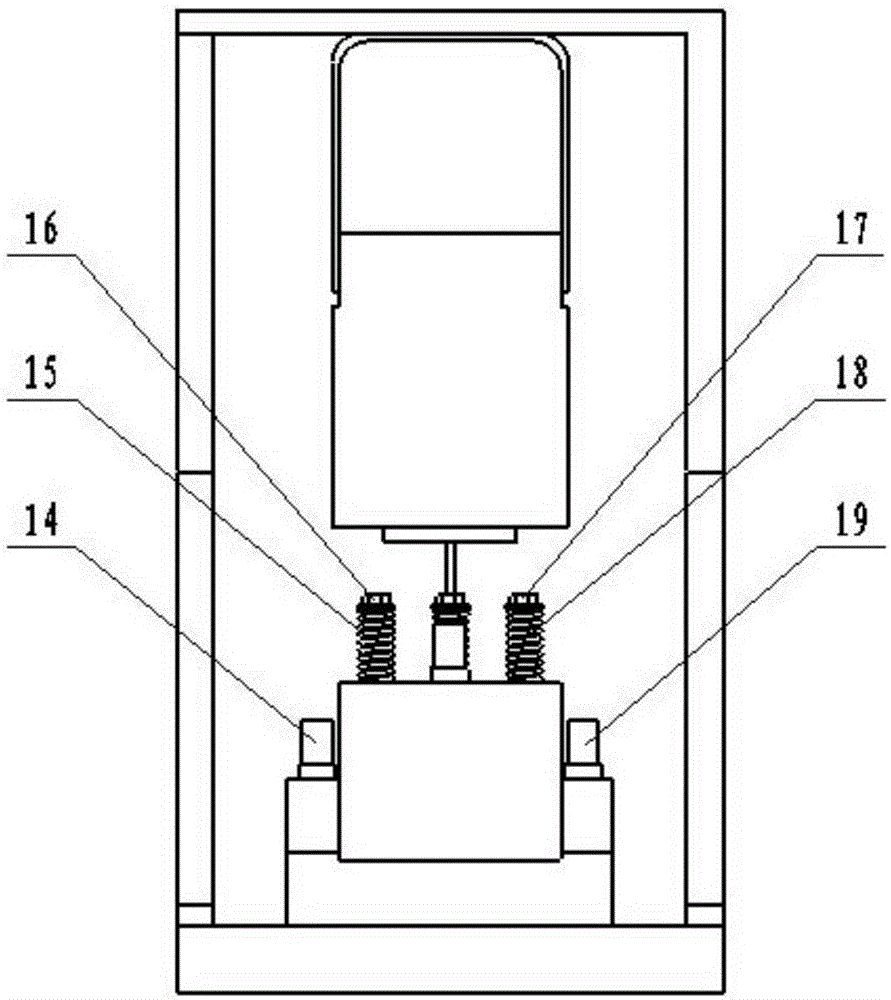

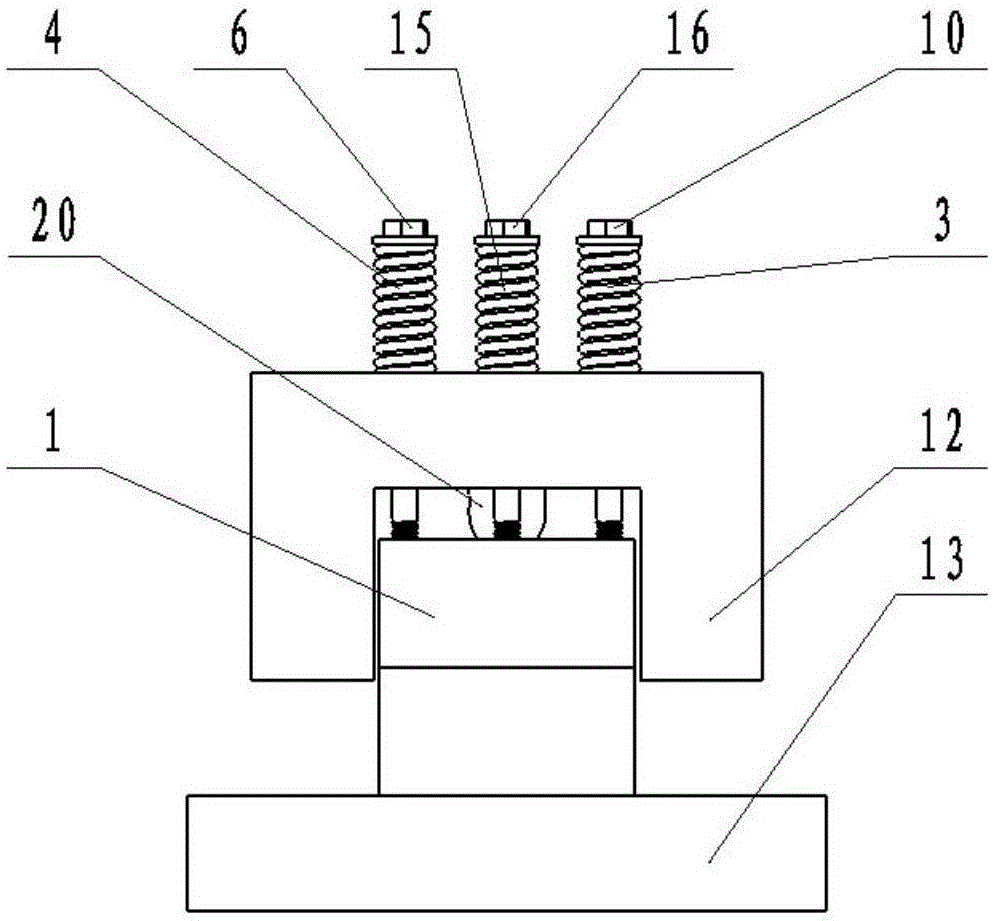

[0040] Attached below Figure 1 to Figure 8 The specific embodiment of the present invention is described further:

[0041] A device for testing the dynamic characteristics of an articular joint surface, the test device comprising a vibration excitation device and a signal acquisition, analysis and processing device; the vibration excitation device is composed of a vibration excitation system, a loading system, and a test bench system;

[0042] figure 1 It is the overall assembly diagram of the measuring device, which is divided into three parts, namely the excitation system, the loading system and the test bench system.

[0043] like figure 1 and figure 2 As shown, the excitation system consists of an exciter (8), an exciter hanging beam (7) and a bracket (9). During use, the bracket (9) plays the role of supporting the exciter (8). Firstly, the bracket (9) is fixed to the base (13) by bolts, and then the vibration exciter hanging beam (7) passes through Fix the bolts w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com