An opgw direct current ice melting system

A DC ice-melting and ice-melting technology, applied in instruments, thermometers, electrical components, etc., can solve the problems that are not mentioned, and achieve the effect of improving the level of intelligence, enhancing the effectiveness of disaster prevention and mitigation, and strengthening the practical application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

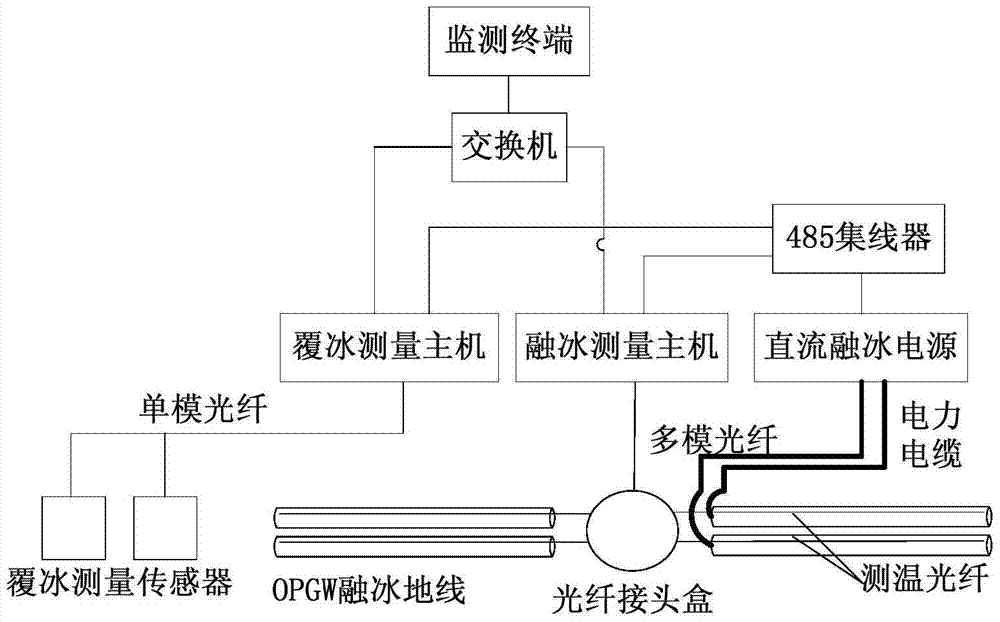

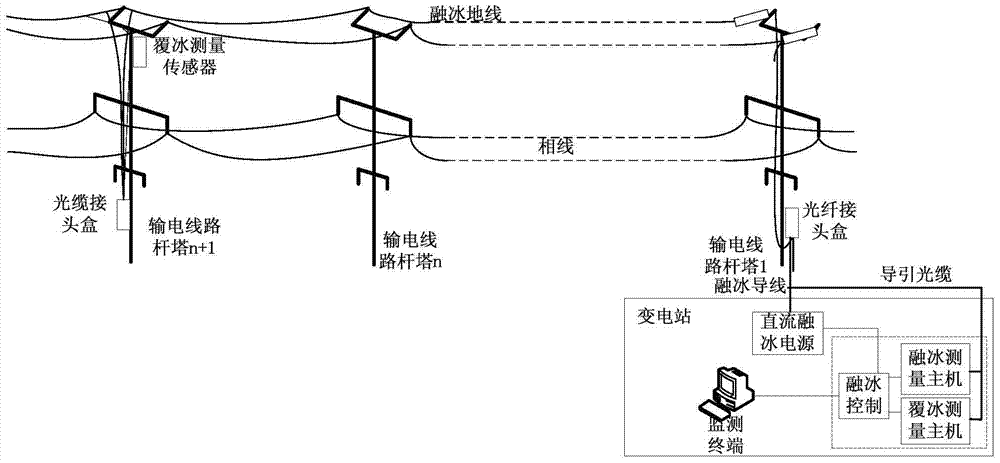

[0037]According to the current monitoring technology level and line engineering construction requirements, the ice melting measurement host and the ice coating measurement host are installed in the machine room of the substation. After modulation, it is sent back to the grating demodulation host to parse the ice thickness data; the ice melting measurement optical signal is also sent from the host of the substation, and returns to the demodulation host of the substation with the temperature information of the optical cable distribution, and the temperature of the optical cable is obtained after analysis. data. Through the data analysis of the monitoring software in the background, the ice coating thickness of the optical cable and the temperature state of the optical cable are mastered, and the start / stop of the ice melting device is controlled, and the meltin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com