Nanoparticles of Disulfiram Loaded on Polyester Materials and Its Application, Pharmaceutical Preparations and Its Application

A technology for pharmaceutical preparations and nanoparticles, which can be applied to medical preparations without active ingredients, medical preparations containing active ingredients, and drug combinations, etc., which can solve the problems of low loading efficiency, few successful reports, and leakage of nanoparticles. drug and other problems, to achieve the effect of effective loading and ensuring drug stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation of the disulfiram nanoparticles described in this application can be prepared by the nanoprecipitation method or the thin film emulsification method, specifically:

[0044] Mix disulfiram or its derivatives, polyethylene glycol-polyester block copolymer, polycaprolactone and solvent, then mix with water for injection, stir, dialyze the organic solvent and filter to obtain disulfiram nanoparticles Solution.

[0045] Or use the following method to prepare the disulfiram composition:

[0046] The solution of disulfiram nanoparticles obtained above is mixed with trehalose and freeze-dried to obtain a freeze-dried powder of disulfiram nanoparticles.

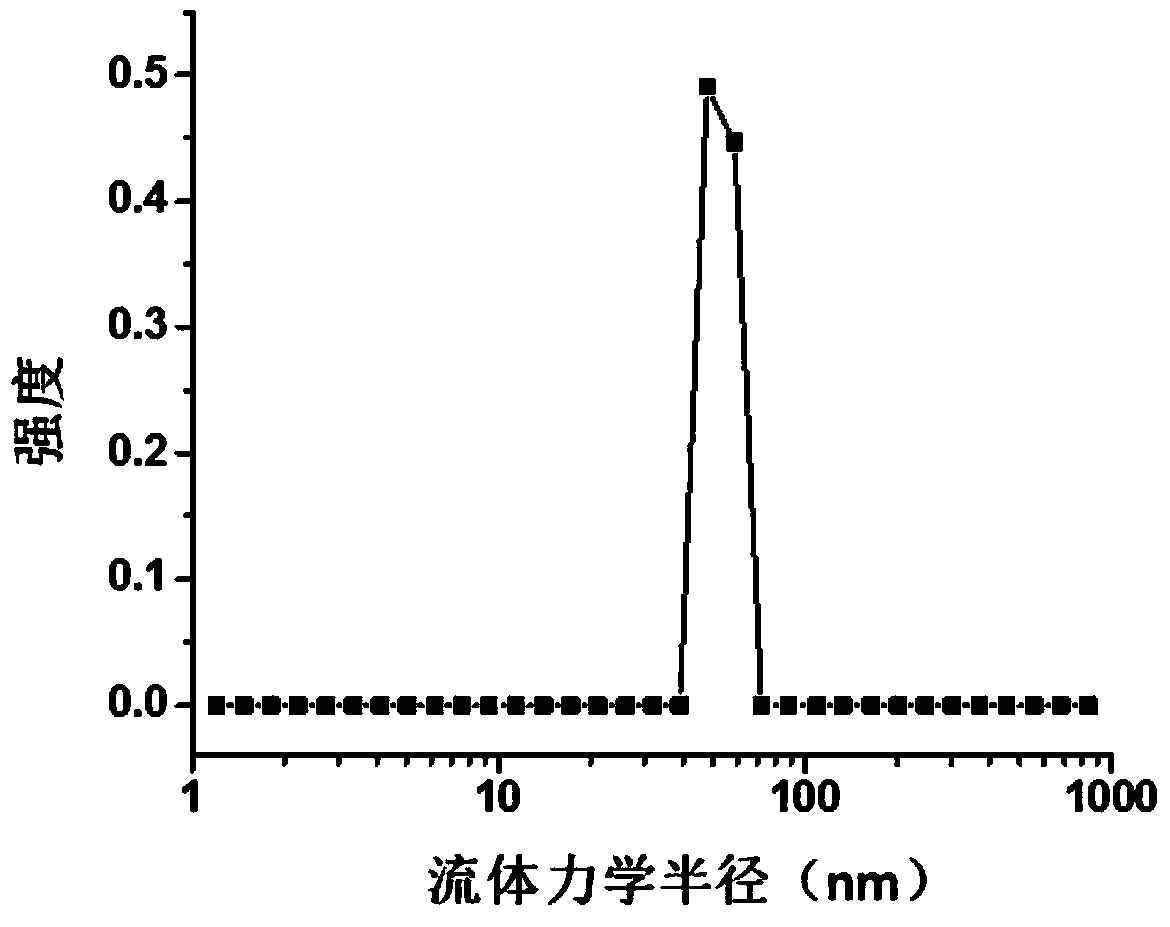

[0047] The disulfiram composition of the present application preferably has a particle size of 20 to 200 nm, and it is a solution or dry powder.

[0048] The disulfiram nanoparticles provided by the present invention propose to use the mixed material of polyethylene glycol-polyester block copolymer and poly-caprolactone ...

Embodiment 1

[0054] Example 1 Preparation of disulfiram nanoparticles

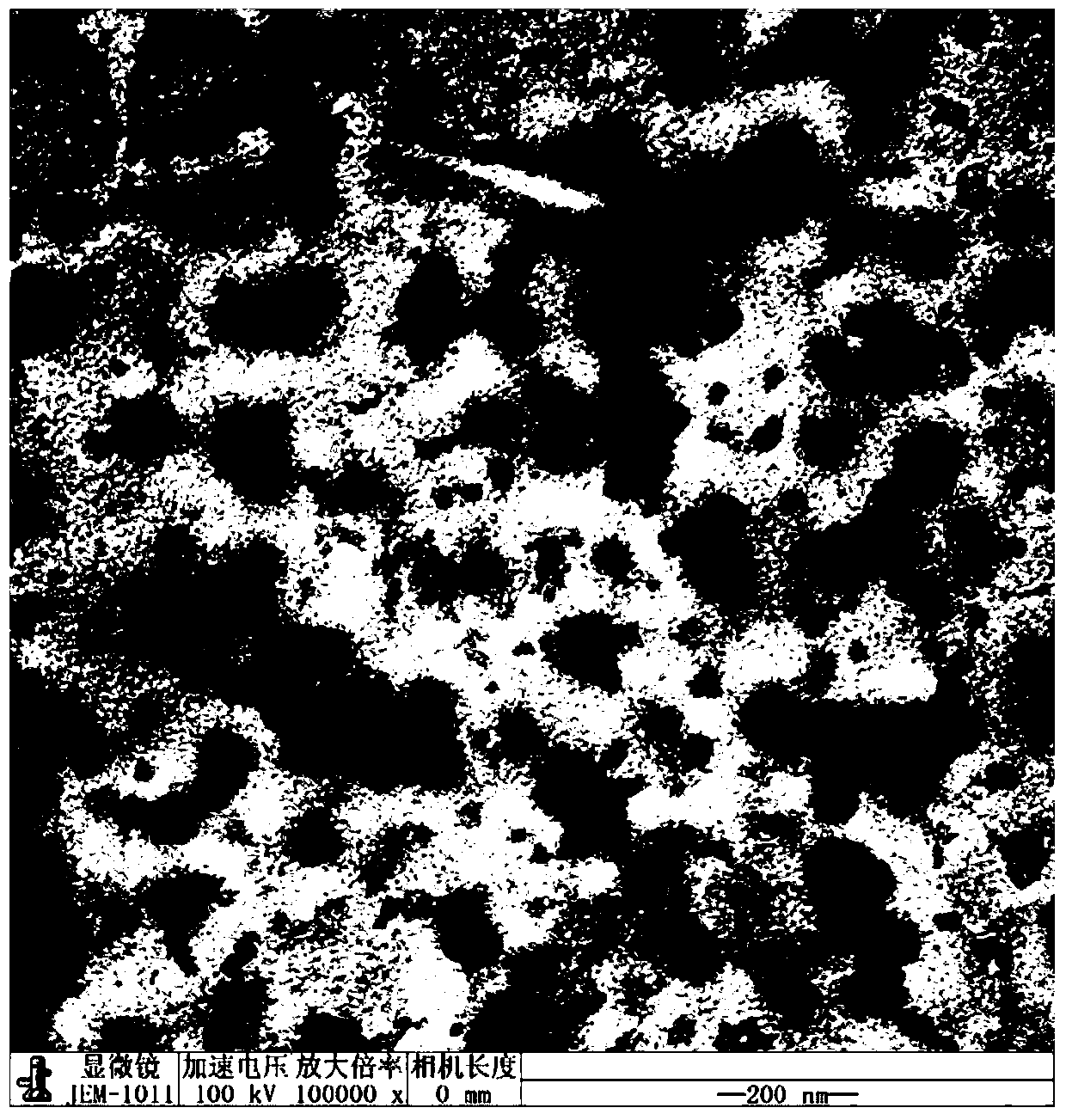

[0055] Take 1.0g of disulfiram, polyethylene glycol-polyglycolide block copolymer (number average molecular weight: polyethylene glycol 5000Da, polyglycolide 2000Da) 3.0g, polycaprolactone (number average molecular weight) : 3400Da) 6.0g, dissolved in 500mL of a mixed solvent of acetonitrile and DMF (v / v=1 / 1), and then added dropwise to 2.0L of water for injection with stirring. After the dripping is completed, the stirring is continued for 2 hours, and then the organic solvent is dialyzed off, filtered, and the solution of disulfiram nanoparticles is collected. Such as image 3 As shown, image 3 This is a transmission electron micrograph of the disulfiram nanoparticles prepared in this example.

Embodiment 2

[0056] Example 2 Preparation of freeze-dried disulfiram nanoparticles

[0057] The disulfiram nanoparticle solution prepared in Example 1 is mixed with trehalose (the mass of which is the volume of the disulfiram nanoparticle solution×5%), and freeze-dried to obtain a freeze-dried powder of disulfiram nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com