Preparation method for bismuth ferrite BiFeO3 nanosheet

A technology of nanosheets and bismuth ferrite, which is applied in chemical instruments and methods, iron compounds, sustainable manufacturing/processing, etc., can solve the problem of high energy consumption, and achieve the effects of simple equipment, energy saving, and intact crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

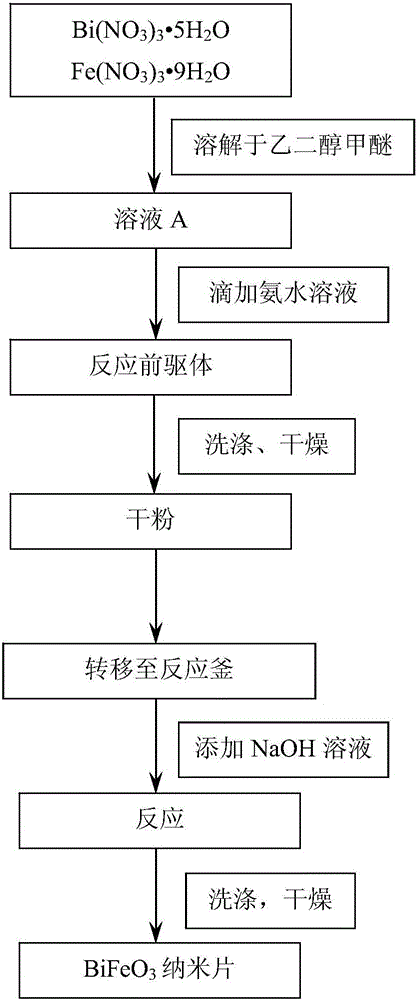

[0035] Such as figure 1 As shown, the BiFeO of this example 3 The preparation process includes the following steps:

[0036] Weigh 2mmol of analytically pure Fe(NO 3 ) 3 9H 2 O and 2mmolBi(NO 3 ) 3 ·5H 2 O, and stir and dissolve it in 20ml of ethylene glycol methyl ether solution, and stir it magnetically for 0.5h to form a uniform solution A; while stirring magnetically, mix 5ml of 8mol / L ammonia solution at 5mL / min The titration rate was added dropwise to solution A, and magnetically stirred for 0.5h to obtain a hydrothermal reaction precursor; the hydrothermal reaction precursor was centrifugally washed with deionized water to neutrality, and dried at 80°C to obtain a dry powder; the dry powder and concentration 4mol / L NaOH aqueous solution (as a mineralizer) is put into a hydrothermal reaction kettle with a filling degree of 80%; the reaction kettle is sealed, and the reaction kettle is placed in an oven at 140°C, and the product in the reaction kettle is taken out ...

Embodiment 2

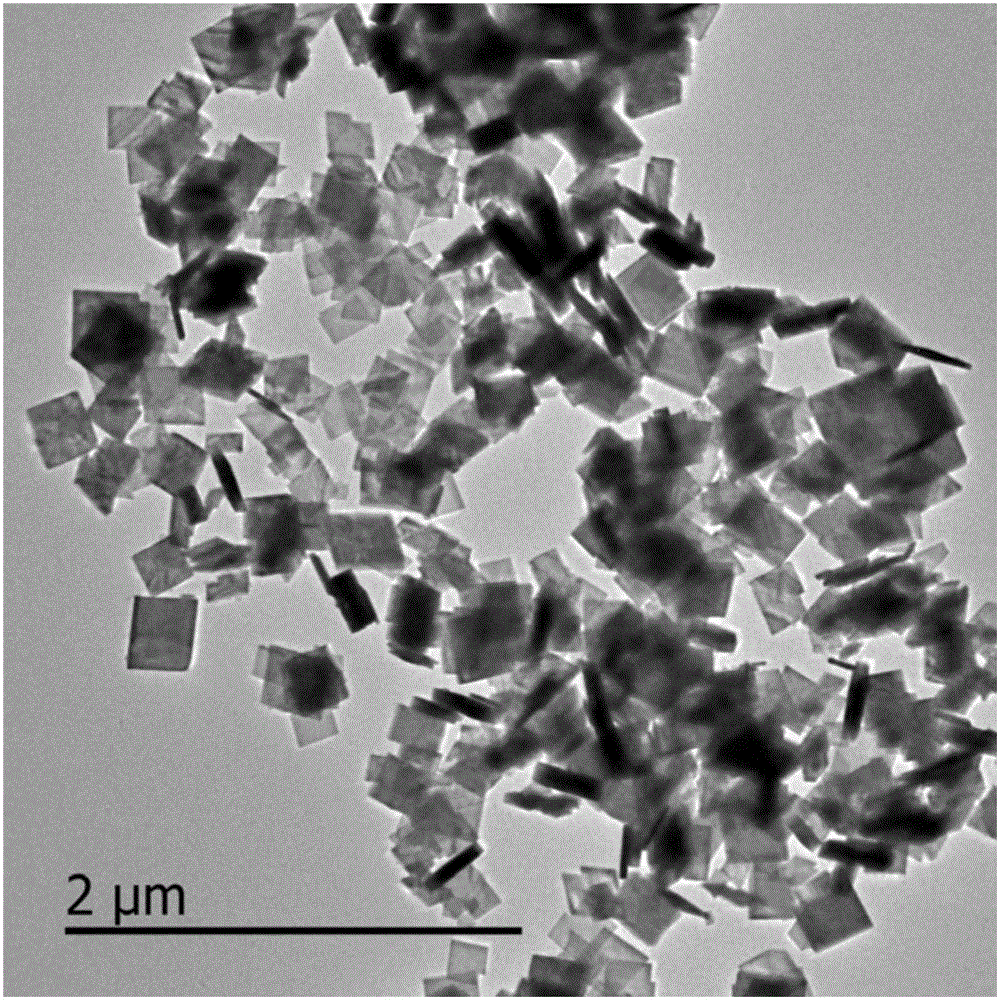

[0040] Weigh 1mmol of analytically pure Fe(NO 3 ) 3 9H 2 O and 1mmolBi(NO 3 ) 3 ·5H 2 O, and ultrasonically dissolve it in 10ml of ethylene glycol methyl ether solution, and ultrasonically dissolve it for 0.5h to form a uniform solution A; while stirring magnetically, dissolve 5ml of 7mol / L ammonia solution at Add dropwise to solution A at a titration rate, and stir magnetically for 0.5h to obtain a hydrothermal reaction precursor; wash the hydrothermal reaction precursor to neutrality and dry at 85°C to obtain a dry powder; mix the dry powder with NaOH with a concentration of 2mol / L The aqueous solution (as a mineralizer) is put into a hydrothermal reaction kettle with a filling degree of 90%; the reaction kettle is sealed, and the reaction kettle is placed in an oven at 120°C. Dry in an oven at ℃ to get bismuth ferrite BiFeO 3 Nanosheets. The pure phase bismuth ferrite BiFeO prepared in this embodiment 3 The nanosheets crystallize well, and the size is between 100nm ...

Embodiment 3

[0044] Weigh 3mmol of analytically pure Fe(NO 3 ) 3 9H 2 O and 3mmolBi(NO 3 ) 3 ·5H 2 O, and dissolve it in 20ml of ethylene glycol methyl ether solution, and stir it magnetically for 0.5h to form a uniform solution A; while stirring magnetically, mix 5ml of 9mol / L ammonia solution at 3mL / min Add dropwise to solution A at a titration rate, and stir magnetically for 0.5h to obtain a hydrothermal reaction precursor; wash the hydrothermal reaction precursor to neutrality, and dry it at 90°C to obtain a dry powder; dissolve NaOH in absolute ethanol with a ratio of In the mixed solution of 0.5% water and absolute ethanol, it is configured into a 3mol / L NaOH solution; then the dry powder and the NaOH solution (as a mineralizer) with a concentration of 3mol / L are put into the hydrothermal reaction kettle, and the filling degree is 70%; seal the reactor, place the reactor in an oven at 130°C, take out the product in the reactor after reacting for 16 hours, wash and dry in an oven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com