Preparation method of insulating paint of lithium ion battery

A technology for lithium ion batteries and insulating coatings, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of slurry dispersion uniformity and poor consistency, improve uniformity, solve slurry agglomeration, and be beneficial to The effect of mass promotion of production applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

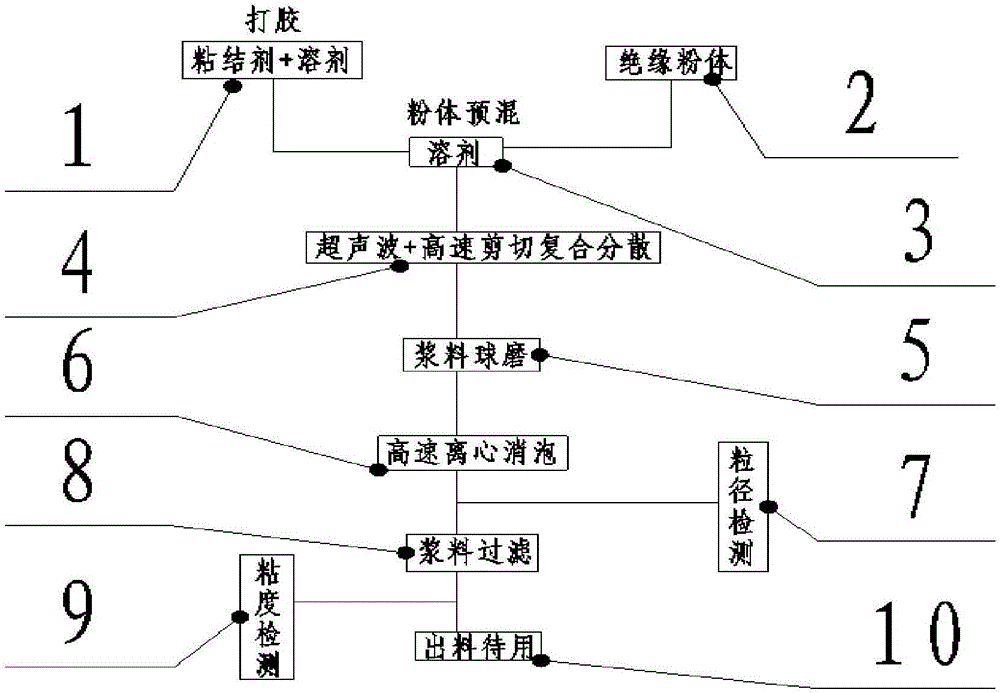

[0024] The preparation method of the lithium-ion battery insulating coating of the present embodiment, process flow chart is as follows figure 1 shown, including the following steps:

[0025] 1) In the mixing tank 1, gradually add carboxymethyl cellulose into water (mass ratio 1:40), and stir for 5 hours at 200 rpm to obtain a binder glue;

[0026] 2) Under the agitation of 250rpm, add the barium sulfate (median particle size is 0.5 μm) in the feeding tank 2 and the adhesive glue obtained in step 1) into the premixing mixing tank 3 for more than two times and mix them , each time after adding the insulating powder, alternately add the binder glue into the slurry premixing mixing tank 3, and the interval of alternate feeding is 10min; after the insulating powder and the binder are added, continue to stir at 300rpm 1h, the mixture was obtained;

[0027] 3) Send the mixture obtained in step 2) into the ultrasonic and high-speed shear composite dispersing device 4, set the dispe...

Embodiment 2~5

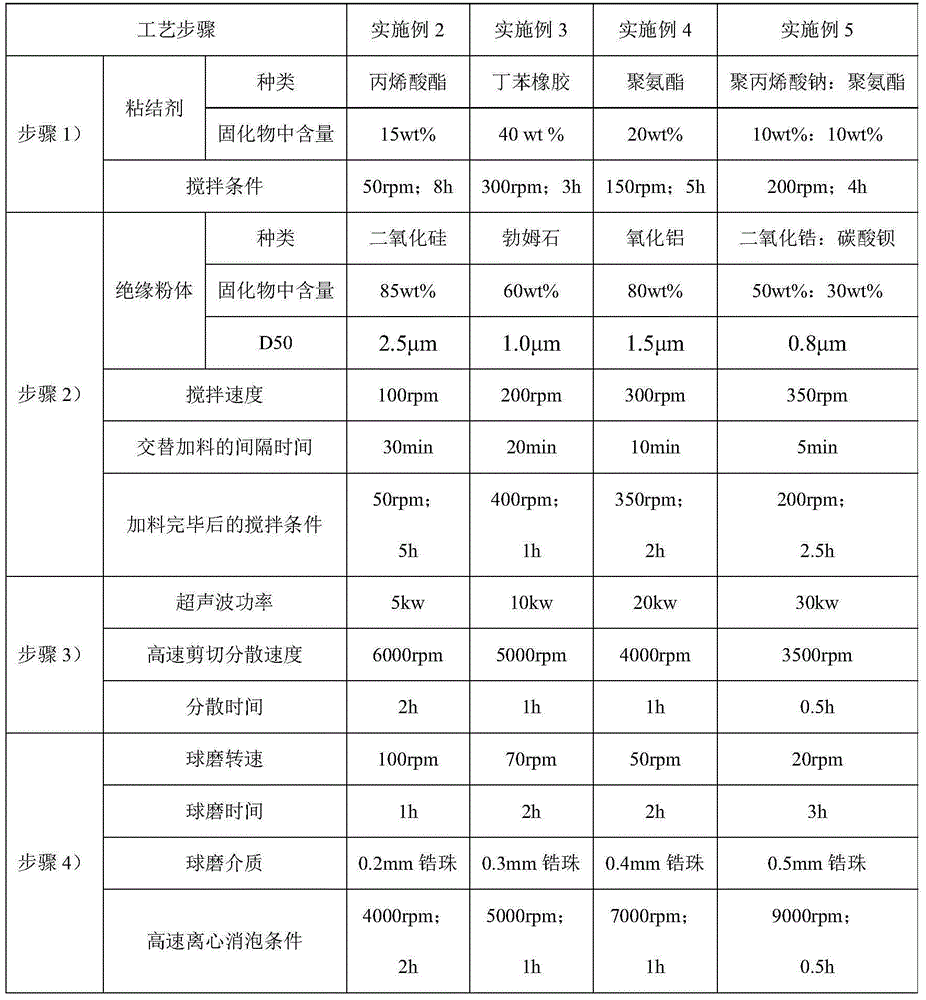

[0031] The preparation methods of the insulating coatings for lithium-ion batteries in Examples 2-5 are basically the same as those in Examples, and the specific differences are listed in Table 1 below.

[0032] The process parameter of the preparation method of table 1 embodiment 2~5 lithium-ion battery insulation coating

[0033]

[0034] The insulating coatings for lithium-ion batteries prepared in Examples 1-5 were coated on the interface between tabs and active materials, and their insulating effects were tested. The results are shown in Table 2.

[0035] Table 2 Comparison of Insulation Resistance of Insulation Coatings in Different Examples

[0036]

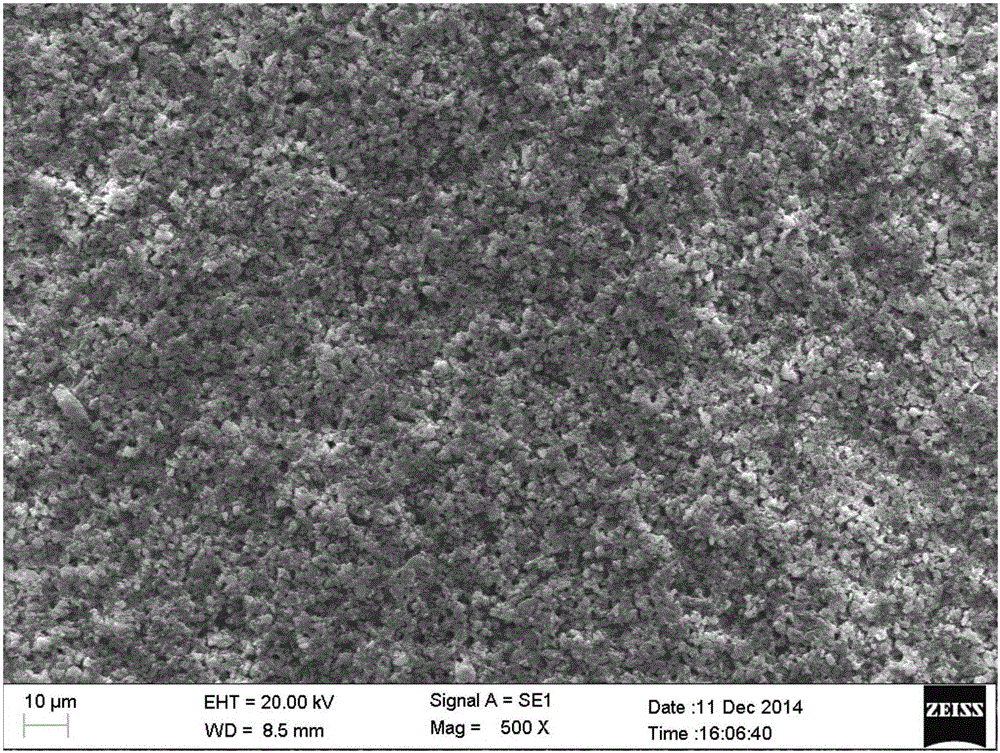

[0037] figure 2 Scanning electron microscope pictures of the insulating coating for lithium-ion batteries prepared in Example 1 of the present invention. Depend on figure 2 It can be seen that the coating particles are evenly distributed and have high consistency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com