Double-leaf spring type shaftless drift soft joint

A leaf spring type and leaf spring technology is applied in the field of double leaf spring type shaftless compliant joints. and fatigue life, avoid the introduction of assembly errors, and reduce the internal stress of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

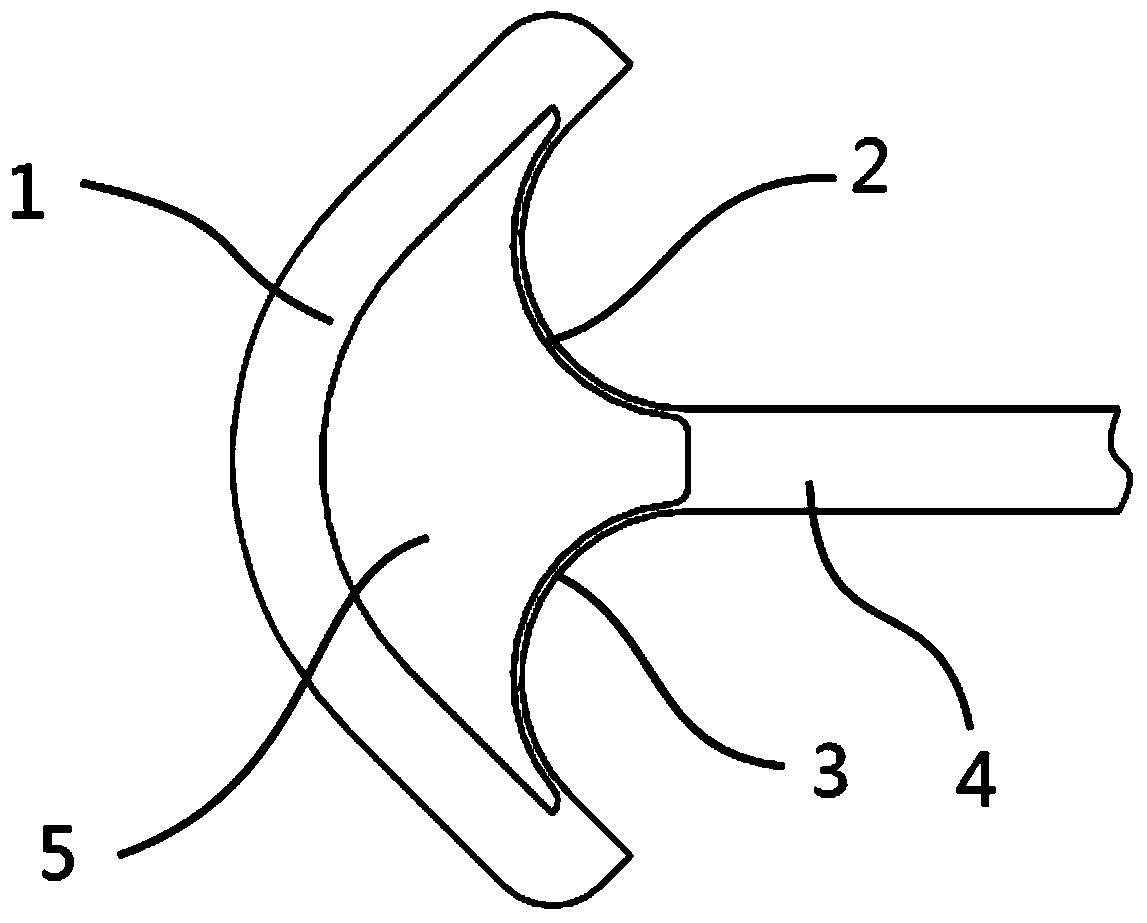

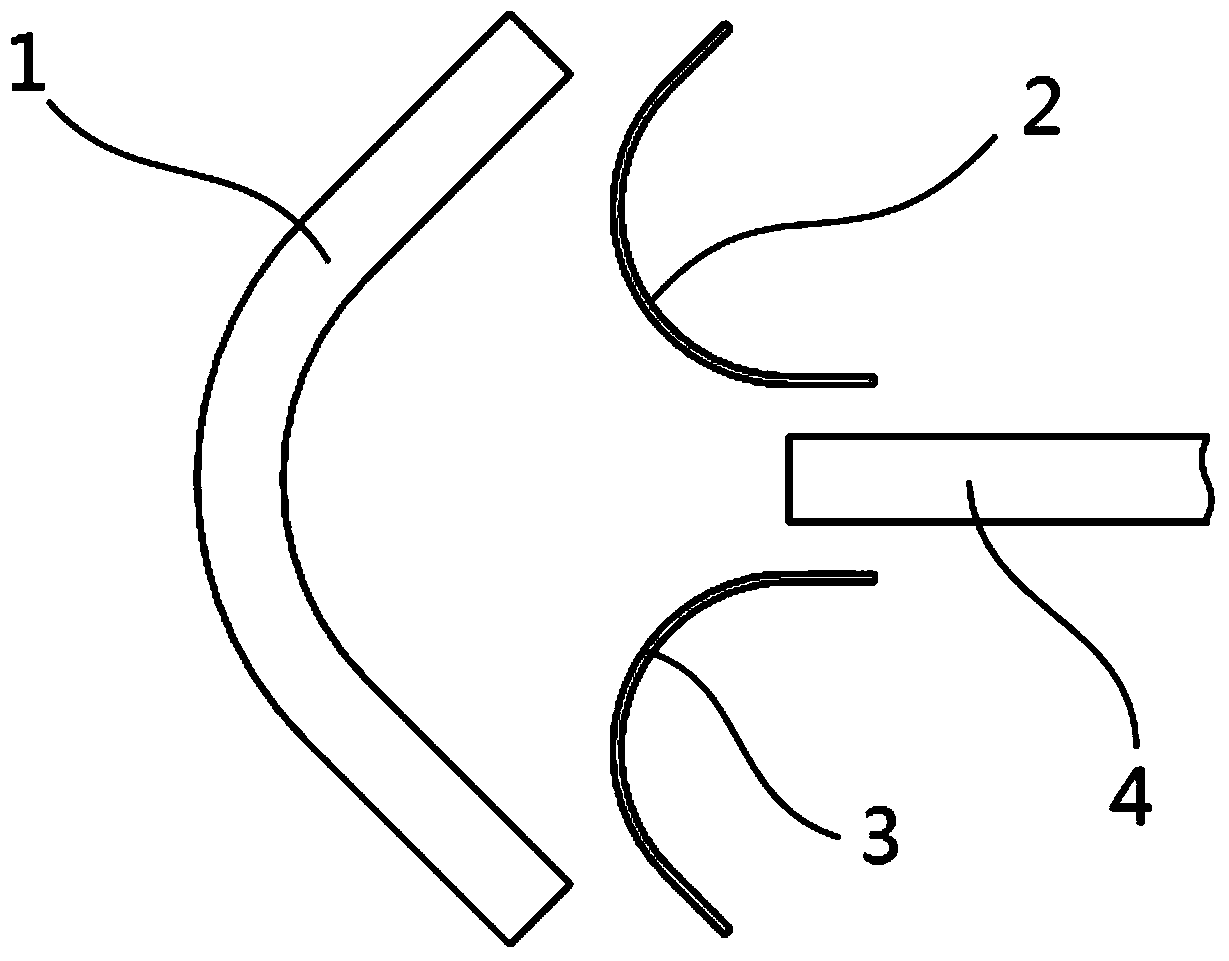

[0016] combine Figure 1-Figure 3 The present invention is described further:

[0017] A double-leaf spring type shaftless drift compliance joint, which includes a left connecting rod 1 , an upper leaf spring 2 , a lower leaf spring 3 , a right connecting rod 4 and a hollow area 5 . It can adopt wire cutting machine tool for integrated processing or split processing and assembly. The integrated processing is to cut the left connecting rod 1 and the right connecting rod 4 on the left and right sides of a rectangular cube, and cut the upper leaf spring 2 and the lower leaf spring 3 symmetrically on the upper and lower sides, and the upper leaf spring 2, The lower leaf spring 3 forms a hollow area 5 with the left connecting rod 1 . Split-type processing and assembly is to process the left connecting rod 1, upper leaf spring 2, lower leaf spring 3, and right connecting rod 4 respectively, and then assemble them by bolt connection or welding.

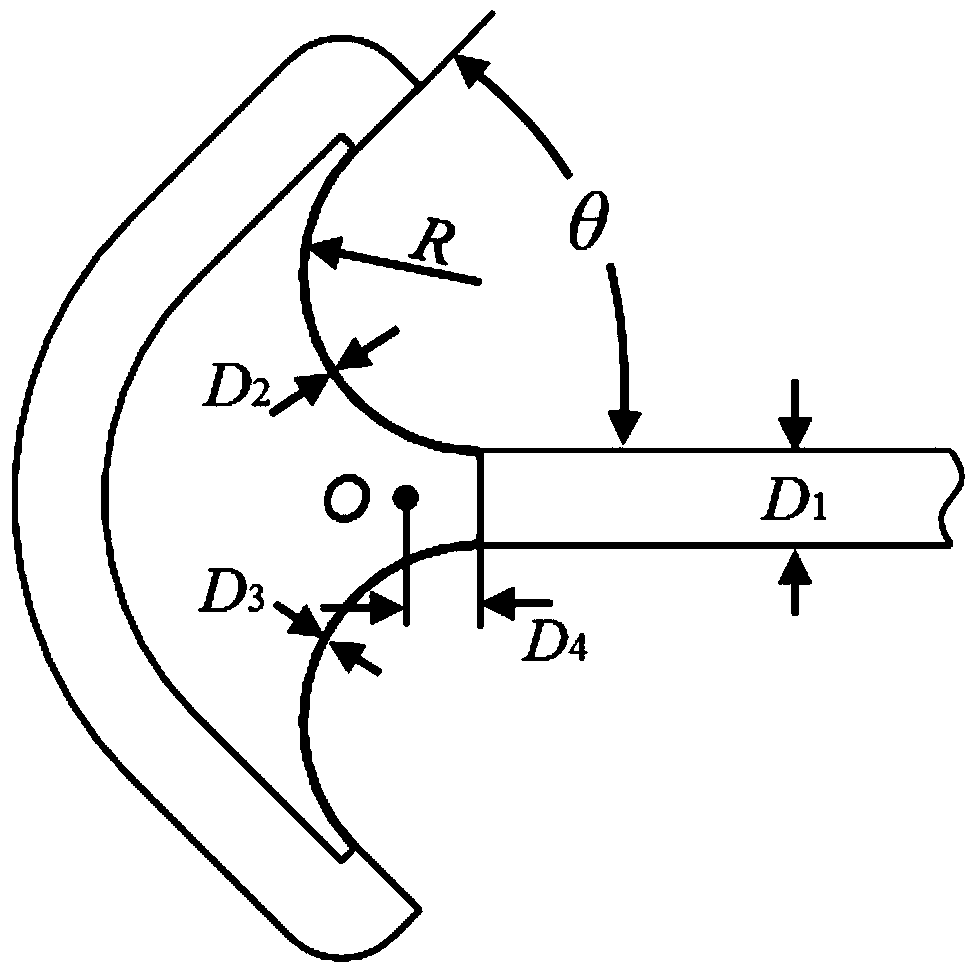

[0018] The arc-shaped upper leaf s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com