Preparation method for molybdenum disulfide coating of brake pad for high-speed train

A technology of brake pads and molybdenum disulfide, which is applied to coatings, devices for coating liquid on the surface, friction linings, etc., can solve problems such as complex deposition shapes, degradation of coating performance, and susceptibility to chemical erosion. Achieve the effects of simple process, short production cycle and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

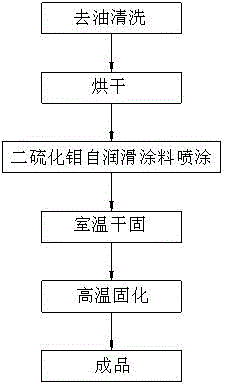

[0022] A kind of preparation method of brake pad molybdenum disulfide coating for high-speed train, such as figure 1 shown, including the following steps:

[0023] (1) Degrease and clean the product to be sprayed to make the surface smooth and free of oil or grease; then use mechanical polishing or chemical treatment to treat the uneven surface of the product to be sprayed to enhance the coating effect;

[0024] (2) After drying the product to be sprayed, use a small spray gun to spray molybdenum disulfide self-lubricating paint onto the surface of the product to be sprayed to form a thin coating at a distance of 10-20 cm from the surface of the product to be sprayed to obtain a sprayed part;

[0025] (3) After the sprayed parts are dried at room temperature for 20 minutes, put the sprayed parts in the baking equipment for curing. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com