Single-compressor secondary dynamic refrigeration cold-storage air-conditioning system and refrigeration method thereof

A single-compressor and air-conditioning system technology, which is applied to compressors, irreversible cycle compressors, refrigerators, etc., can solve the problems that equipment cannot operate independently, achieve low equipment investment and operation costs, stable cooling, and avoid The effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

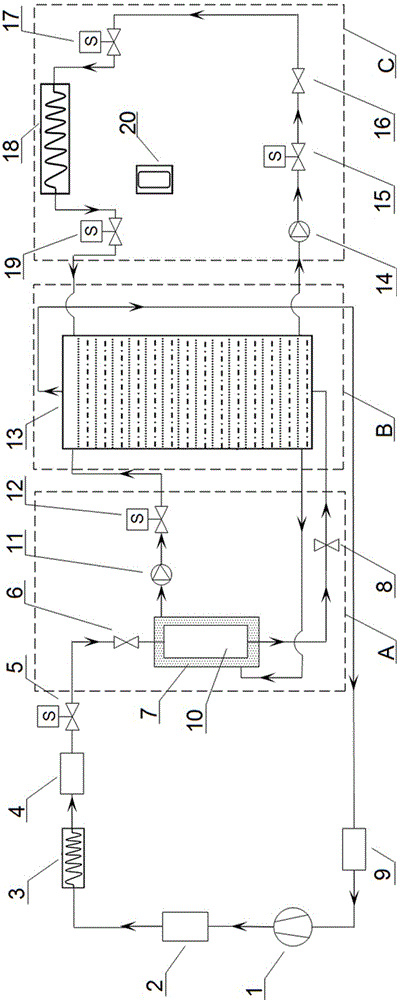

Embodiment 1

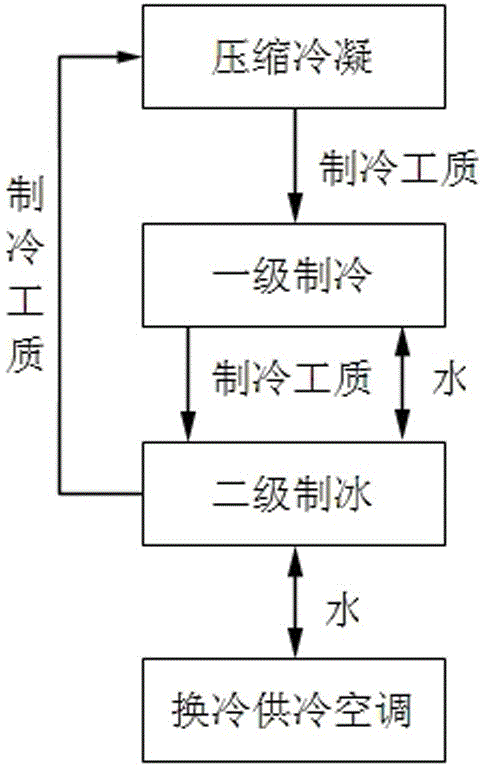

[0041] like image 3 As shown, the refrigeration method of the single-compressor two-stage dynamic series refrigeration cold storage air conditioner is as follows:

[0042] A. Compression and condensation: Compressor 1 compresses the refrigerant sent by gas-liquid separator Ⅱ9 into a compressed gas with a temperature of 40°C and a pressure of 1.5MPa, and then condenses it into a gas with a temperature of At 30°C and a pressure of 1.5 MPa, the liquid flows into the liquid reservoir 4 and is controlled and stored by the solenoid valve I5;

[0043] B. Primary refrigeration: adjust the opening size of the solenoid valve Ⅰ5 according to the cooling demand, and the refrigerant is throttled by the throttle valve Ⅰ6 to become a refrigerant with a temperature of 5°C and a pressure of 0.5MPa, and flows into the evaporator 7 to absorb heat and refrigerate to a temperature of 10°C, gas with a pressure of 0.7MPa, the evaporator 7 is immersed in the heat exchanger 10 filled with refrigeran...

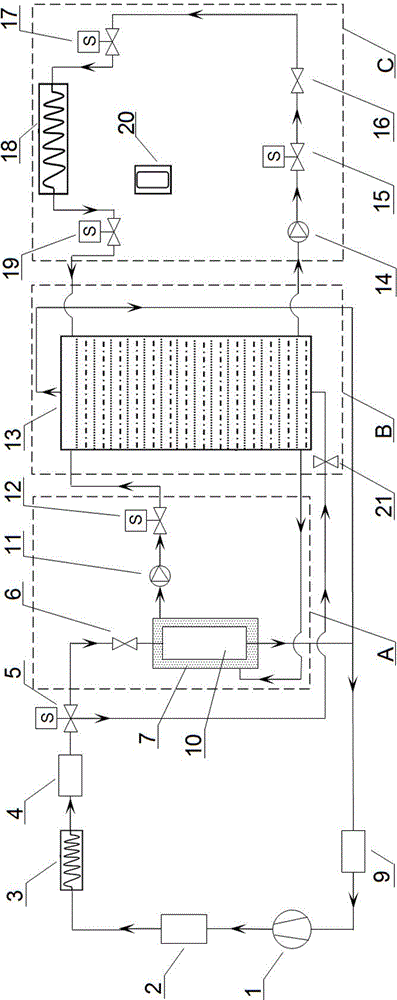

Embodiment 2

[0048] like Figure 4 As shown, the separate production of cold water for the single compressor two-stage dynamic parallel refrigeration cold storage air conditioner is as follows:

[0049] A. Compression and condensation: Compressor 1 compresses the refrigerant sent by gas-liquid separator Ⅱ9 into a compressed gas with a temperature of 45°C and a pressure of 1.8 MPa, and then condenses it into a gas with a temperature of At 35°C and a pressure of 1.8 MPa, the liquid flows into the liquid receiver 4, and the flow direction of the refrigerant and the flow rate of the flow in each direction are controlled by the three-way solenoid valve I5;

[0050] B. Primary refrigeration: control the three-way solenoid valve Ⅰ5 to throttle all the refrigerant through the throttle valve Ⅰ6 into a refrigerant with a temperature of 7°C and a pressure of 0.6MPa, and flow into the evaporator 7 to absorb heat and cool down to a temperature of 12°C , gas with a pressure of 0.8 MPa, the evaporator 7...

Embodiment 3

[0055] like Figure 4 As shown, the separate ice production of the two-stage dynamic parallel refrigeration storage air conditioner with a single compressor is as follows:

[0056] A. Compression and condensation: Compressor 1 compresses the refrigerant sent by gas-liquid separator Ⅱ9 into a compressed gas with a temperature of 35°C and a pressure of 1.2MPa, and then condenses it into a gas with a temperature of At 25°C and a pressure of 1.2MPa, the liquid flows into the liquid receiver 4, and controls the flow direction and flow velocity of the refrigerant in all directions through the three-way solenoid valve I5;

[0057] B. Primary refrigeration: do not open the opening of the three-way solenoid valve I5 to the evaporator 7, so that cold water is not produced;

[0058] C. Secondary ice making: control the three-way solenoid valve I5 to throttle all the refrigerant after compression and condensation to 0-1°C refrigerant through the throttle valve III21, and flow into the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com