Conductive particle and preparation method thereof, conductive adhesive and display apparatus

A technology of conductive particles and conductive adhesives, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, conductive adhesives, cable/conductor manufacturing, etc., can solve the problems of difficult processing of carbon materials and large changes in conductivity, etc. Achieve the effect of avoiding agglomeration problems and improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

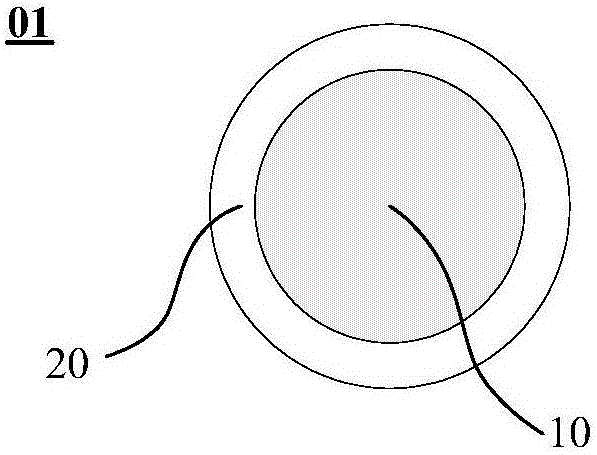

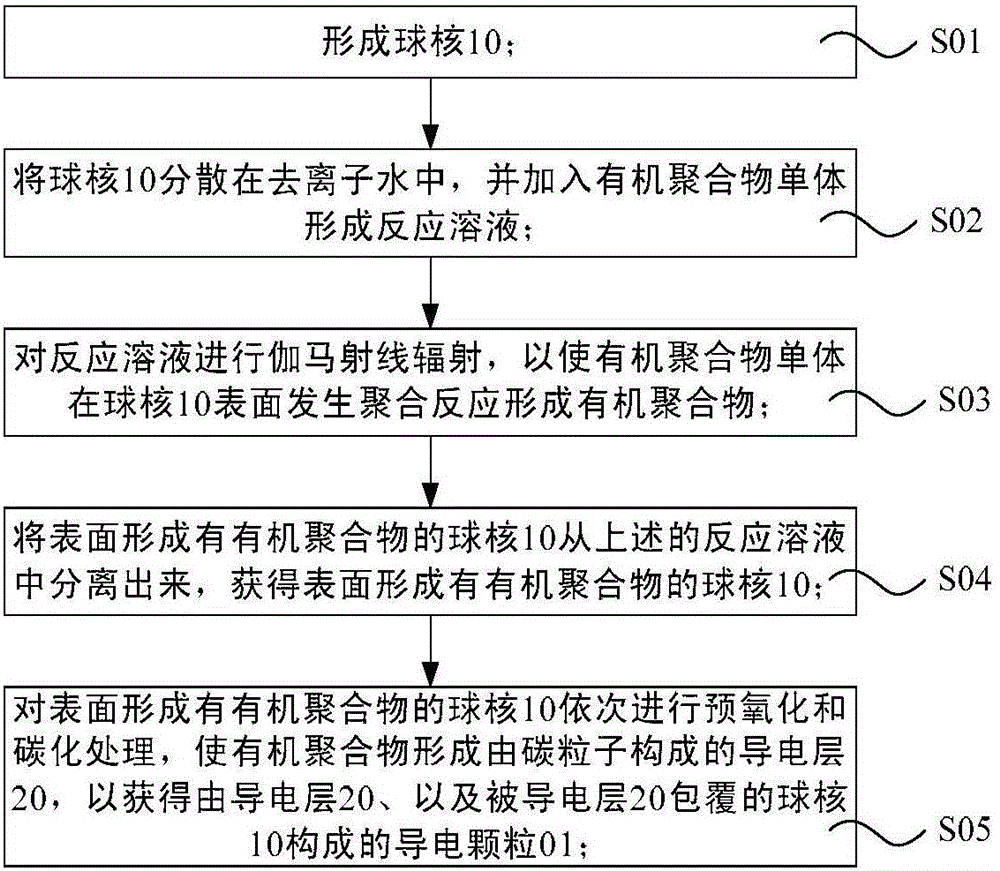

[0045] Embodiments of the present invention provide a figure 1 The preparation method of the conductive particle 01 shown, such as figure 2 Shown, this preparation method comprises:

[0046] S01, forming a spherical core 10;

[0047] S02, dispersing the spherical core 10 in deionized water, and adding organic polymer monomers to form a reaction solution;

[0048] S03, irradiating the reaction solution with gamma (γ) rays, so that the organic polymer monomer undergoes a polymerization reaction on the surface of the ball core 10 to form an organic polymer;

[0049] S04, separating the core 10 with the organic polymer formed on the surface from the above reaction solution to obtain the core 10 with the organic polymer formed on the surface;

[0050] S05. Carry out preoxidation and carbonization treatment sequentially on the core 10 formed with an organic polymer on the surface, so that the organic polymer forms a conductive layer 20 composed of carbon particles, so as to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com