Routing-free LED packaging structure and preparation method therefor

An LED packaging, wire-free technology, applied in electrical components, electric solid devices, circuits, etc., can solve the problems of complex preparation process, limited by wire bonding conditions and wire yield, and high cost, and achieves simple packaging process, Improve the yield of packaging products and enhance the effect of chip light-emitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

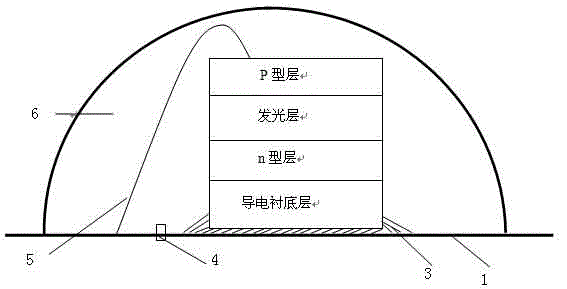

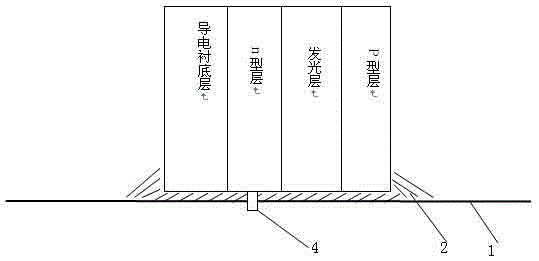

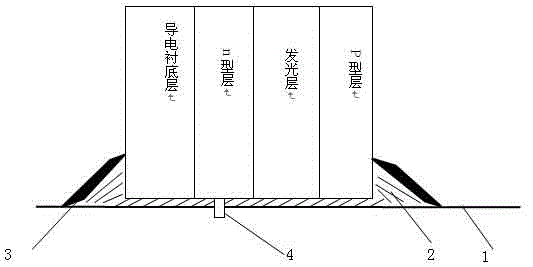

[0024] The wire-free LED packaging structure of the present invention is as follows: Figure 4 As shown, it includes an LED chip and a die-bonding substrate 1. The LED chip is placed sideways on the die-bonding substrate 1, and the two are bonded by insulating die-bonding glue 2. The side of the side-turned LED chip is also coated with insulating die-bonding. Glue, coating conductive silver glue 3 on both sides parallel to the direction of each conductive layer of the LED chip, the conductive silver glue 3 electrically connects the LED chip and the die-bonding substrate 1, and the die-bonding substrate 1 is provided with an insulating partition 4 to connect the The die-bonding substrate 1 is electrically disconnected to form positive and negative poles, which are respectively connected with the conductive silver glue 3 on the two sides of the LED chip. The package structure is suitable for LED chips with a vertical structure.

[0025] The preparation steps of the above-mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com