LED package structure and technology employing glass fluorescence sheet

A technology of LED packaging and fluorescent sheets, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of easy occurrence of defects, non-curing, and broken gold wires, so as to improve production efficiency, product yield and consistency, The effect of simplifying LED packaging steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

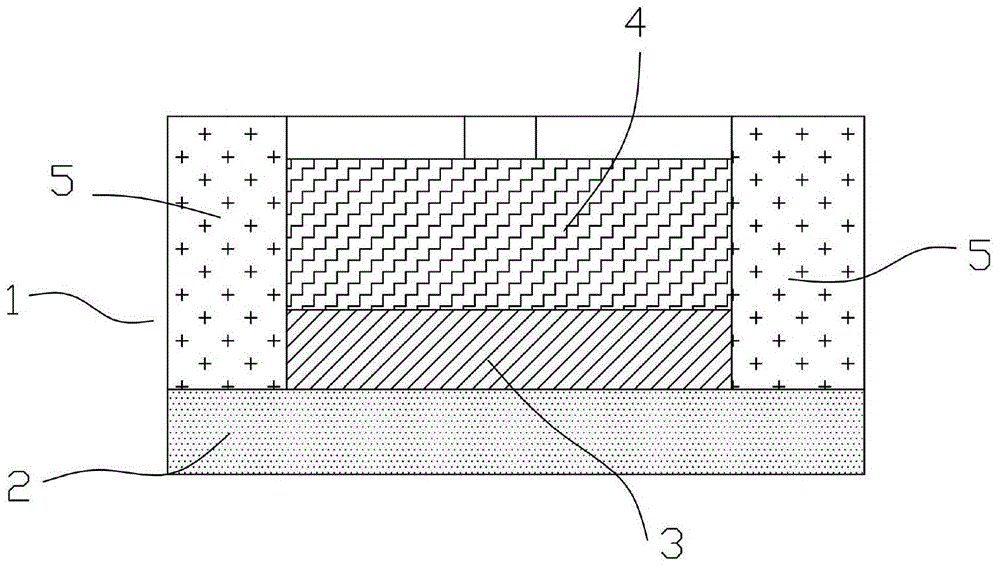

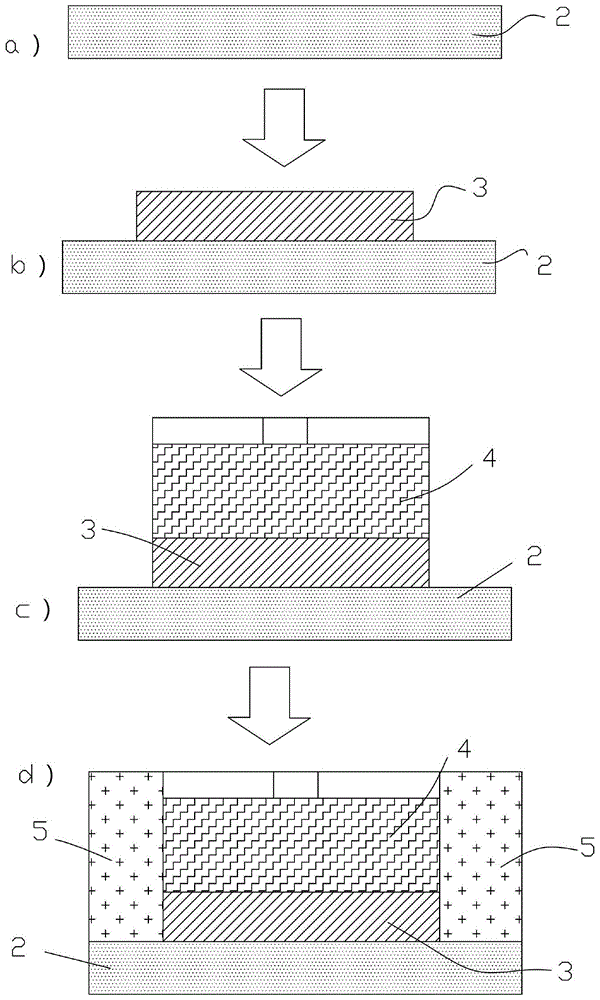

[0028] Such as figure 1 As shown, the LED packaging structure 1 using a glass fluorescent sheet includes a glass fluorescent sheet 2 coated with a crystal-bonding glue 3 , and an LED chip 4 is fixed above the crystal-bonding glue 3 . The LED chip 4 The die-bonding glue 3 is flip-chip mounted, and the gaps between the LED chips 4 are filled with filling glue 5 . It should be pointed out that, when coating the die-bonding glue 3 , it is necessary to use a patterned mask plate or mask sheet to realize the patterned coating of the die-bonding glue. The filler here can act as an optical reflection or block light, and the corresponding material can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com