Wind power generation system having flywheel and one-pole dc magnetic driver

A wind power generation system and flywheel technology, applied in wind power generation, wind turbines, wind turbine combinations, etc., can solve the problems of low total efficiency of variable frequency motor + frequency converter, lower power quality, and unstable wind power generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

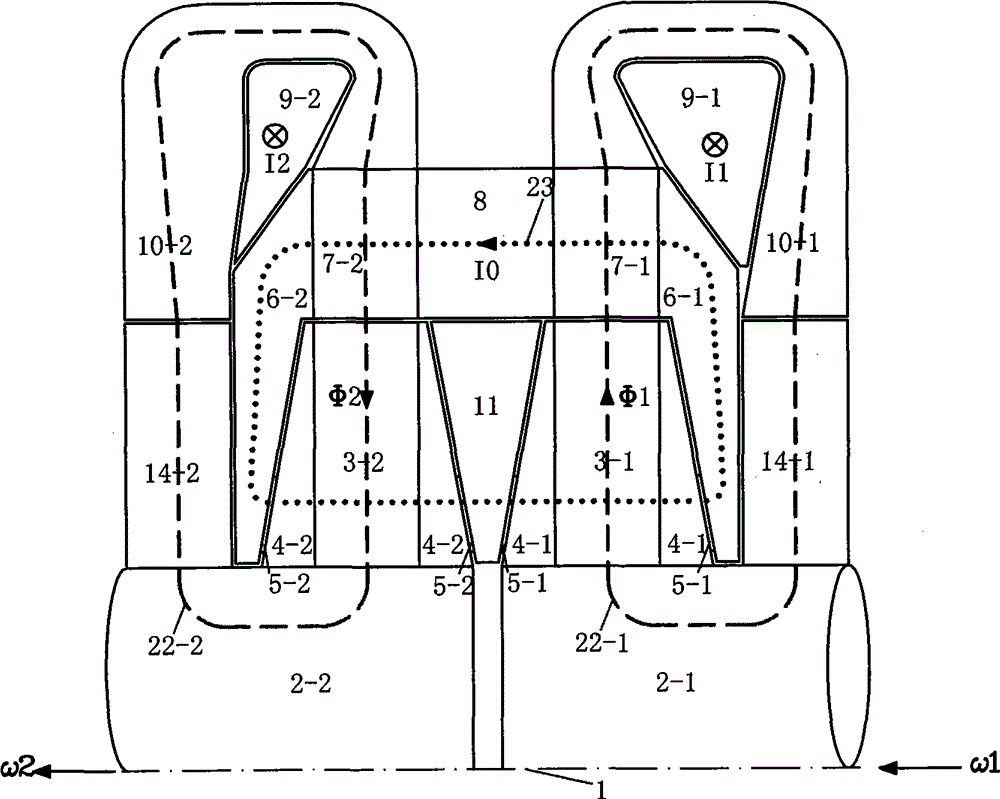

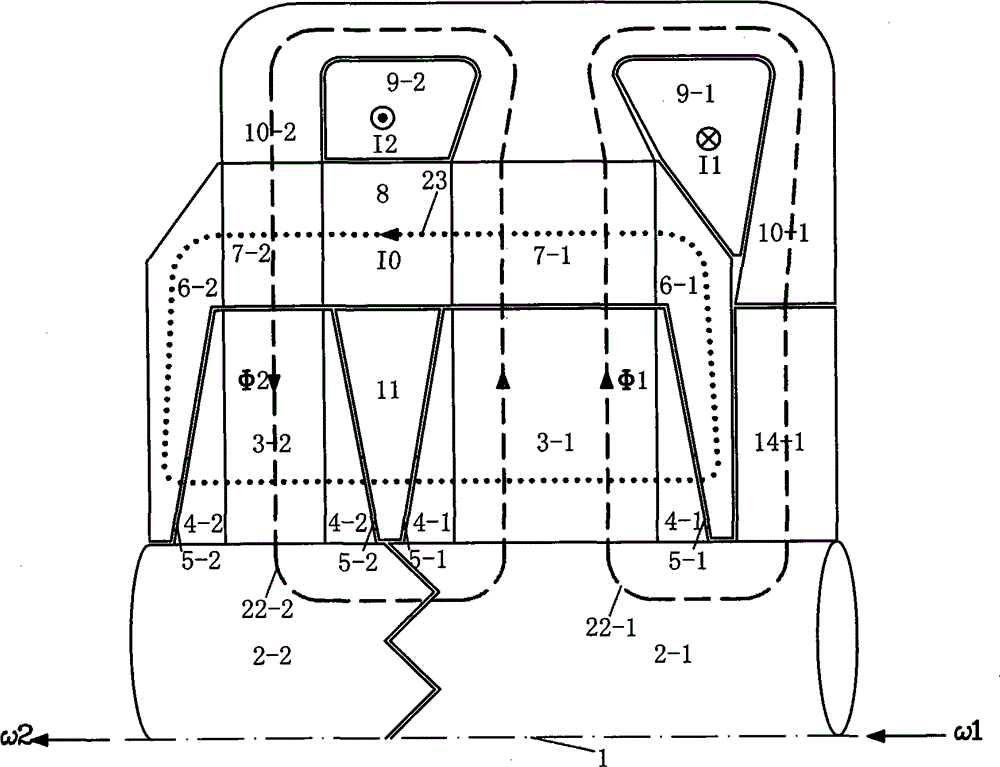

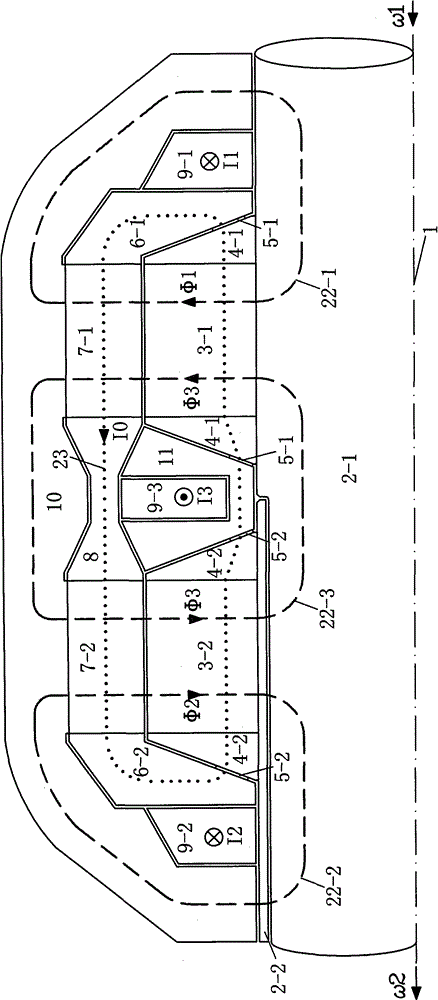

[0265] A 1.5MW wind power system with flywheel and HET ( Figure 21 ) The specific embodiment is as follows.

[0266] The system includes: a horizontal shaft variable-pitch blade rotor, a horizontal speed-up gearbox connected to the rotor shaft, a unipolar DC electromagnetic transmission (HETw) connected to the output shaft of the gearbox and indirectly connected to the generator shaft, A horizontal synchronous generator, a suspended flexible flywheel device, a unipolar DC electromagnetic transmission (HETf) connecting the flywheel shaft and the generator shaft, a mechanical brake device at the wind rotor shaft, and a yaw drive active pair Wind mechanism, a nacelle, a tower, and control and ancillary systems.

[0267] The wind rotor adopts three airfoil profile blades, the maximum value of wind energy utilization coefficient Cp is 0.47, and the corresponding optimal tip speed ratio is 7, and the rated design point applies the optimal tip speed ratio and the maximum Cp value. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com