Halbach array disk-type motor

An array disk and array technology, applied in the field of Halbach array disk motors, can solve the problems of unusable electromagnetic fields, low utilization rate of magnetic energy, insufficient heat dissipation, etc., and achieve a design suitable for popularization and use, simple in structure, and low in cost and weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

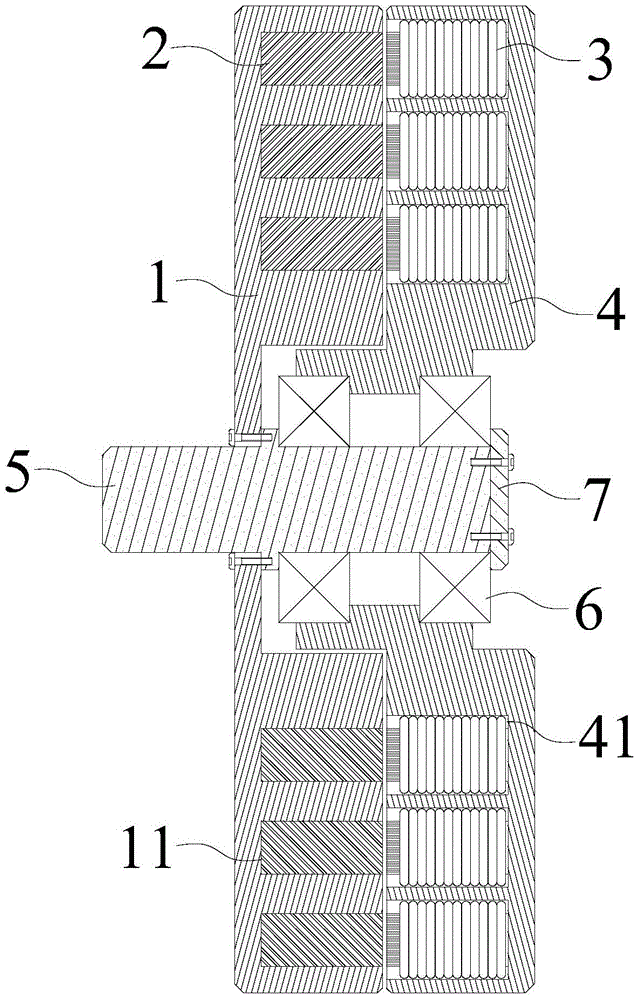

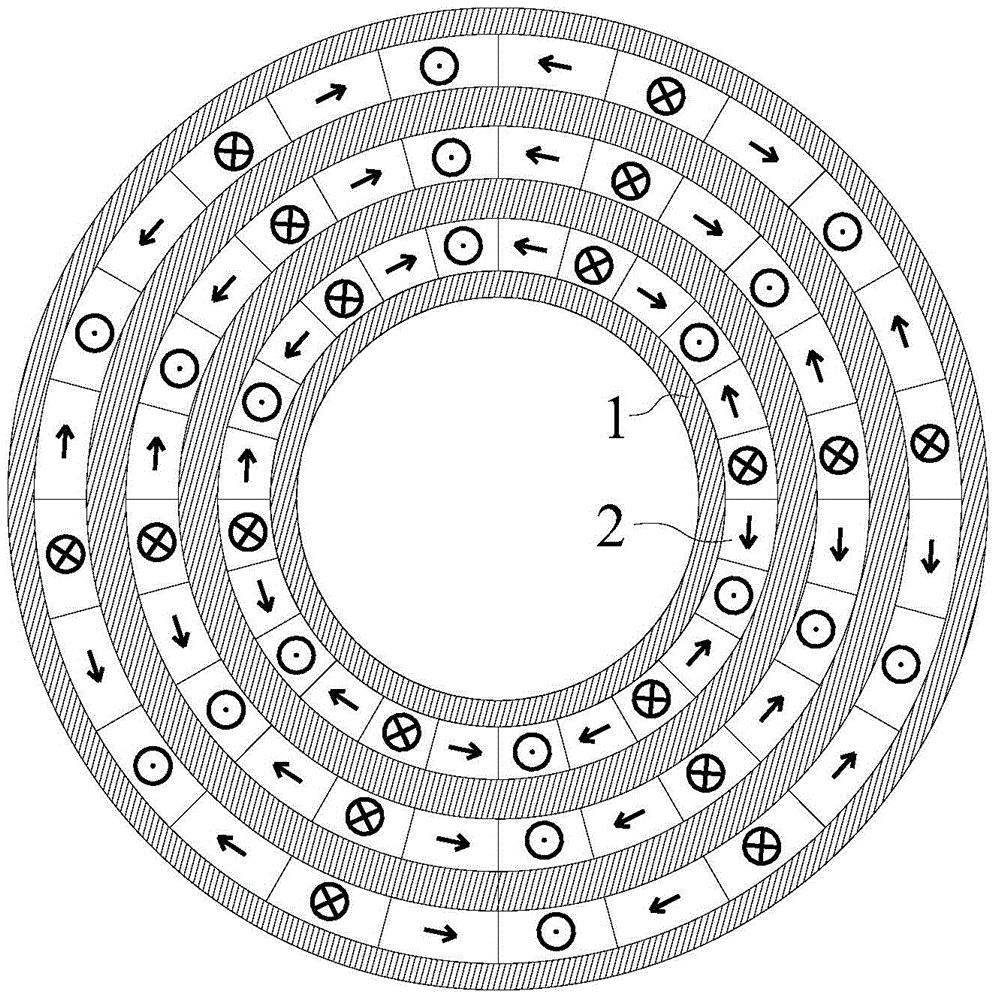

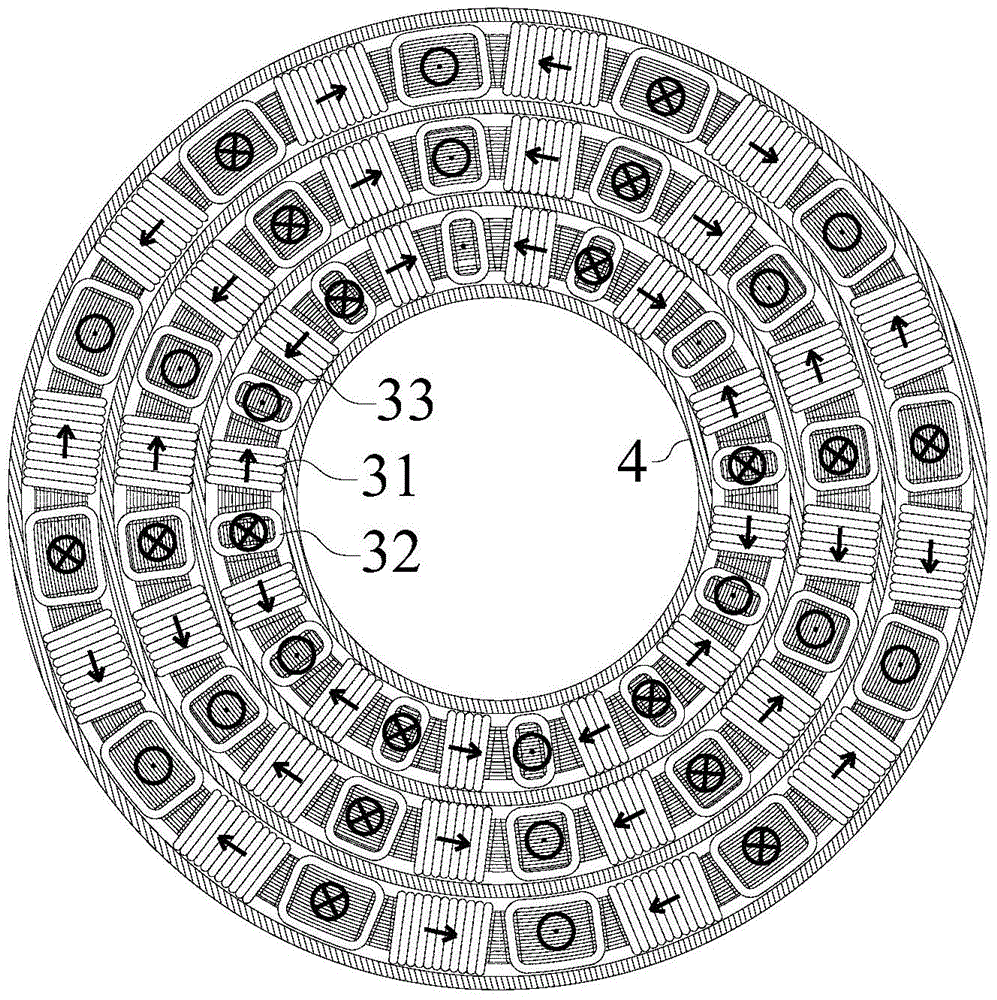

[0028] like Figure 1-4 As shown, the Halbach array disc motor of the present invention includes a rotor, a stator, a fixed shaft 5 connecting the rotor and the stator in series, and a commutation circuit, the stator is connected to the fixed shaft bearing, and the fixed shaft is provided with a boss that is stuck against the bearing , the inner hole of the stator fixed plate is provided with a three-stage stepped hole, the end of the fixed shaft is fixed with a bearing baffle 7, and two bearings 6 are arranged in the three-stage stepped hole and are respectively sandwiched between the bearing baffle and the boss , the boss of the fixed shaft is fixedly connected with the rotor through screws to support the rotor and enh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com