Plant soil loosening device

A technology for rippers and plants, applied in the fields of application, soil preparation machinery, agricultural machinery and implements, etc., can solve the problems of leaving more unrippled areas, difficult access of motor rippers, and large loosening area, etc. High utilization rate of fertilization, beneficial to irrigation and fertilization, and the effect of improving air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

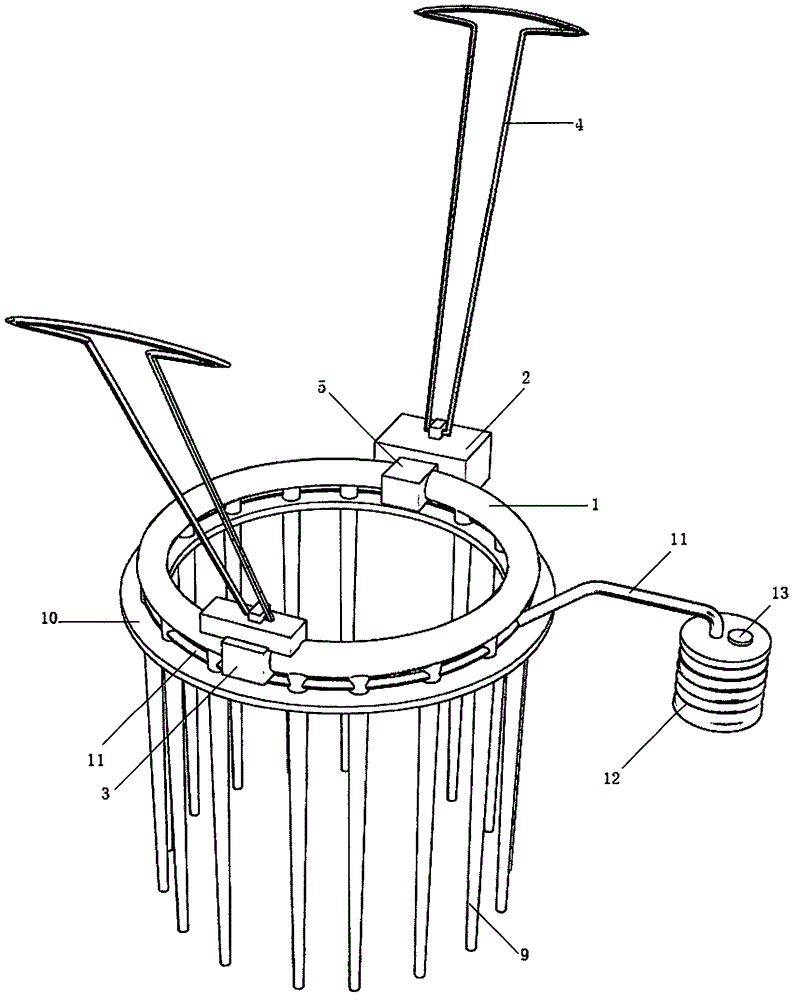

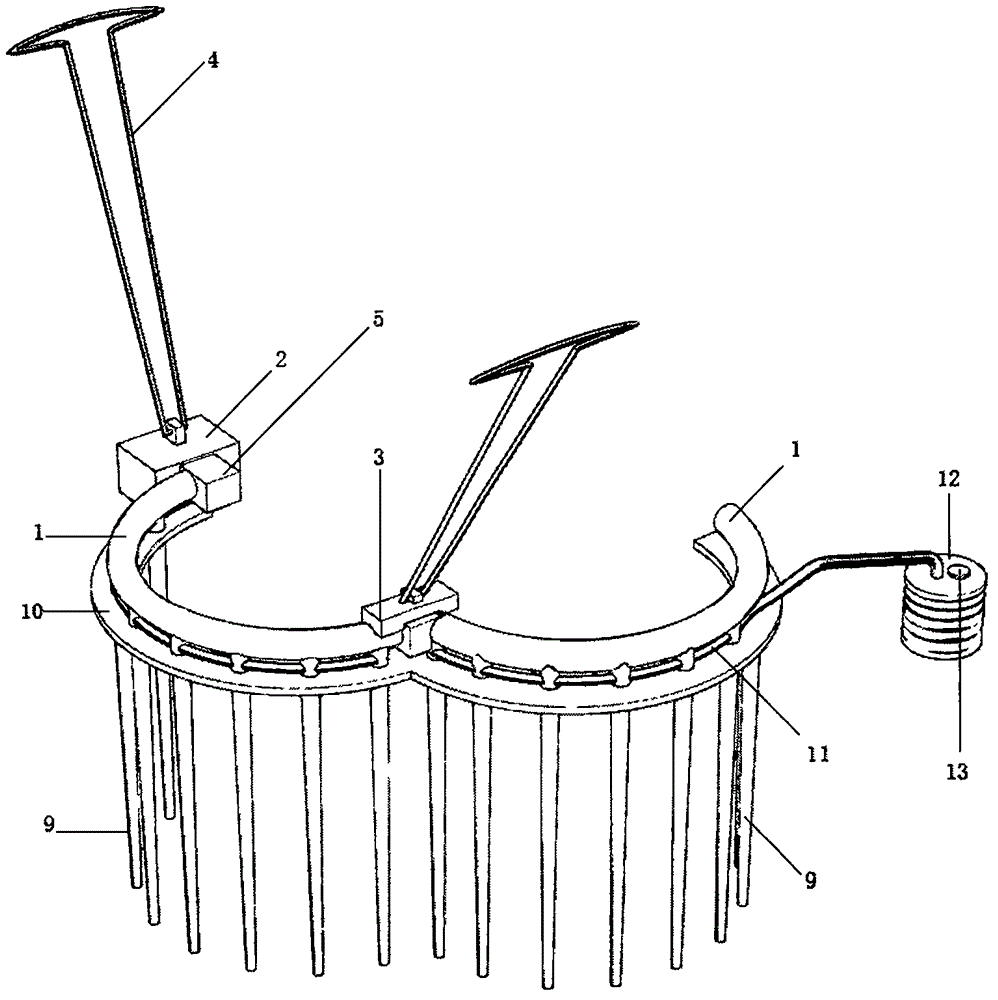

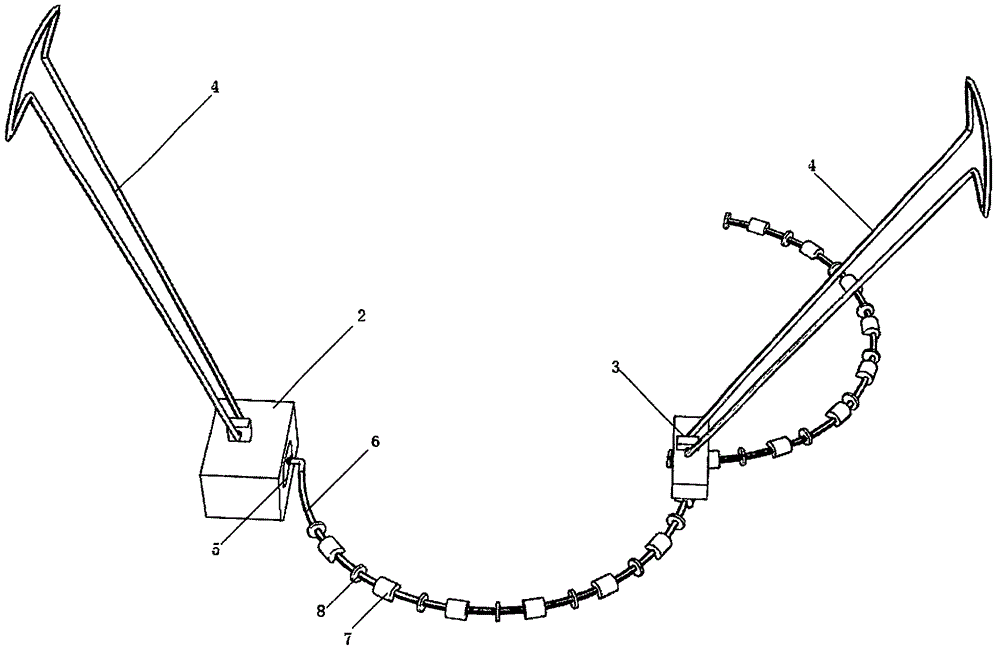

[0016] The plant ripper includes two symmetrically arranged vibrating half-rings 1; one end of the two vibrating half-rings 1 is connected by a rotating shaft and a fixed block 2 is installed on the rotating shaft, and the other end is plugged and fitted with a fixed block B installed on the socket. 3; A fixed block 2 and B fixed block 3 are equipped with a handle 4; A drive motor 5 is installed in the A fixed block 2; the output end of the drive motor 5 is connected to a flexible shaft 6; the flexible shaft 6 passes through two The vibration half-ring 1 circles around in the two vibration half-rings 1; the eccentric rotor 7 is evenly installed on the flexible shaft 6; between the adjacent eccentric rotors 7, the flexible shaft 6 is rotated and connected to the inner wall of the vibration half-ring 1 The supporting wheel 8; the bottom of each vibrating half-ring 1 is evenly equipped with a vertically arranged loosening drill 9; the bottom of each vibrating half-ring 1 is corres...

Embodiment 2

[0020] The difference between this embodiment and embodiment 1 is: on the basis of embodiment 1, each soil ripper 9 inside of the plant ripper is a hollow cavity; the side wall of each ripper 9 is evenly opened with The through hole through which the hollow cavity is connected; the hollow cavity of each soil loosening drill 9 is connected with a hose 11; the end of the hose 11 is connected with a compression capsule 12; the upper part of the compression capsule 12 is equipped with a sealing cover 13.

[0021] This embodiment inherits the operation mode of the embodiment. The soil loosening drill 9 penetrates into the soil when loosening the soil. At this time, the soil looseness is good, which is conducive to irrigation and fertilization, and the utilization rate of irrigation and fertilization is high. At this time, pour water or a mixture of water and fertilizer into the compressed capsule body 12, then press down the compressed capsule body 12, and the liquid enters the soi...

Embodiment 3

[0023] The difference between this embodiment and embodiment 2 is that: on the basis of embodiment 2, the outer wall of each ripper 9 of the plant ripper and the inner wall of the hollow cavity are coated with polytetrafluoroethylene coating.

[0024] This embodiment inherits the operation method of Embodiment 2. The polytetrafluoroethylene coating has strong non-stickiness and corrosion resistance, which can prevent the soil from adhering to the loosening drill 9, and can also prevent the deposition of fertilizing materials from blocking the through hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com